Are you gearing up for a career in Boring Machine Operator Helper? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Boring Machine Operator Helper and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

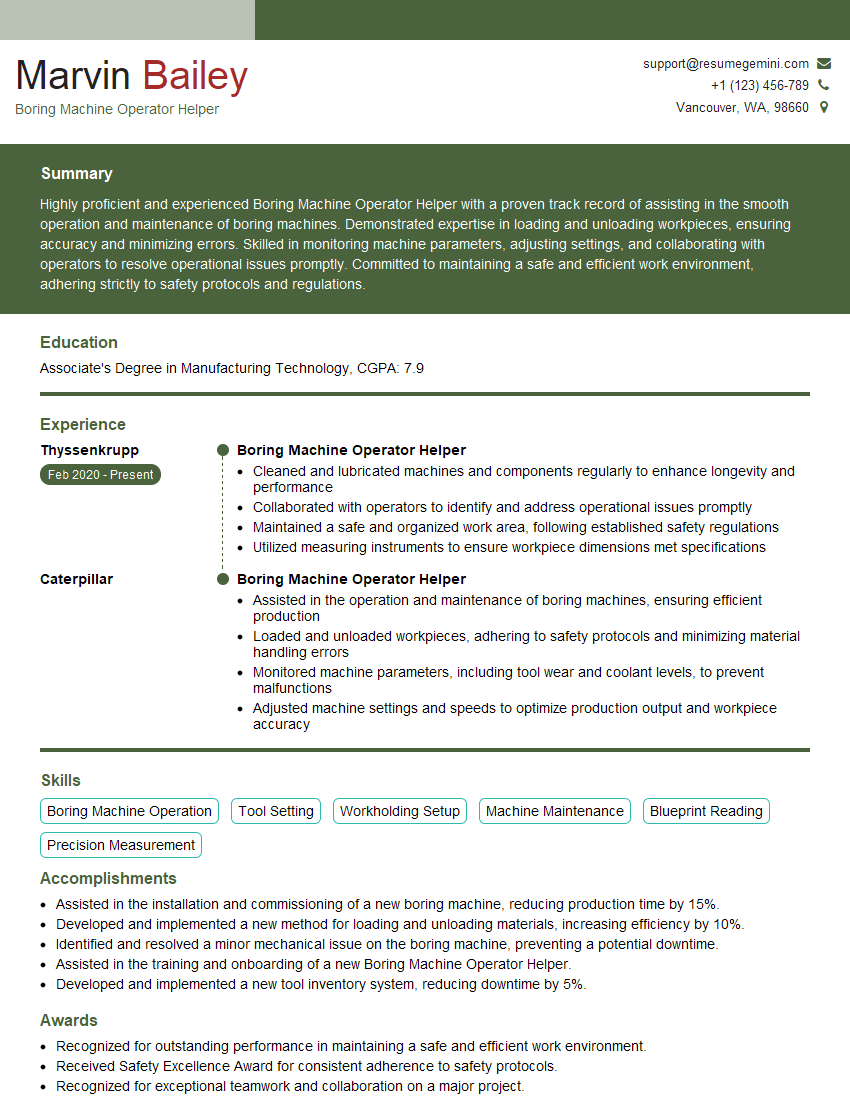

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Boring Machine Operator Helper

1. If the boring machine is vibrating excessively, what could be the possible causes and what steps would you take to troubleshoot and resolve the issue?

- Loose Boring Bar: Check if the boring bar is securely tightened in the tool holder. Loose connections can cause vibrations.

- Unbalanced Workpiece: Ensure that the workpiece is properly centered and balanced on the machine table.

- Worn Bearings: Inspect the bearings on the boring machine for wear or damage.

- Misaligned Tooling: Check if the boring bar or other tooling is misaligned. Improper alignment can lead to excessive vibrations.

2. How do you ensure the accuracy and precision of the boring operation?

Tool Setup and Calibration

- Properly calibrate the boring machine.

- Use sharp and properly sized boring bars.

Process Control

- Maintain consistent cutting speed and feed rate.

- Regularly check the bore diameter and depth with precision measuring instruments.

3. Describe the steps involved in setting up and operating a boring machine.

- Mount the workpiece securely on the machine table.

- Select the appropriate boring bar and tool insert.

- Set the cutting speed, feed rate, and depth of cut.

- Start the boring operation and monitor the process.

- Use coolant or cutting fluid to reduce friction and improve tool life.

4. How do you determine the correct cutting parameters (speed, feed, depth of cut) for a specific boring operation?

- Material Properties: Consider the hardness, machinability, and thermal properties of the workpiece material.

- Boring Bar Characteristics: Take into account the diameter, length, and material of the boring bar.

- Machine Capabilities: Refer to the machine’s specifications for maximum spindle speed and feed rate.

- Experience and Manufacturer’s Recommendations: Utilize knowledge gained from previous operations and consult manufacturer’s guidelines.

5. Explain the difference between rough boring and finish boring.

- Rough Boring: Removes the majority of material, leaving a rough surface finish.

- Finish Boring: Provides the final precise dimensions and desired surface finish.

- Tooling: Rough boring typically uses larger tools, while finish boring employs smaller, more precise tools.

- Cutting Parameters: Rough boring involves higher material removal rates, while finish boring uses slower speeds and feeds for increased accuracy.

6. How do you measure the bore diameter and ensure it meets the required specifications?

- Bore Gauge: Use a bore gauge to measure the inner diameter of the bore.

- Micrometer: Measure the diameter of the boring bar and subtract twice the tool radius to calculate the bore diameter.

- Coordinate Measuring Machine (CMM): For high-precision measurements, utilize a CMM.

7. Discuss the importance of coolant and lubrication in boring operations.

- Heat Reduction: Coolant removes heat generated during cutting, preventing tool wear and workpiece distortion.

- Lubrication: Reduces friction between the tool and workpiece, improving tool life and surface finish.

- Chip Removal: Coolant helps flush away chips, preventing clogging and ensuring smooth cutting.

8. Describe the safety precautions you observe while operating a boring machine.

- Proper Clothing: Wear appropriate safety gear, including gloves, safety glasses, and ear protection.

- Guarding: Ensure that all guards and safety devices are in place and operational.

- Machine Setup: Verify that the workpiece and tooling are securely mounted.

- Emergency Stop: Familiarize yourself with the emergency stop button and know when to use it.

- Chip Handling: Dispose of chips properly to prevent tripping or flying debris.

9. How do you maintain and troubleshoot common problems with boring machines?

Maintenance

- Regularly clean and lubricate the machine.

- Check and replace worn or damaged parts.

- Calibrate the machine to ensure accuracy.

Troubleshooting

- Excessive Vibration: Check for loose components, unbalanced workpiece, or worn bearings.

- Poor Surface Finish: Examine the tool for wear, adjust cutting parameters, or check for coolant issues.

- Inaccurate Bore Diameter: Verify the tool setup, cutting parameters, and machine calibration.

10. How do you stay up-to-date with the latest advancements and best practices in boring operations?

- Training: Attend industry workshops and seminars.

- Technical Publications: Read trade journals and research papers.

- Online Resources: Utilize websites and forums dedicated to boring technology.

- Consult with Experts: Network with experienced machinists and engineers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Boring Machine Operator Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Boring Machine Operator Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Boring Machine Operator Helpers are crucial members of manufacturing teams, assisting skilled operators in the precise operation of boring machines. Their primary responsibilities include:

1. Machine Operation Assistance

Assists in setting up, operating, and monitoring boring machines, ensuring that they perform optimally and produce accurate parts.

- Loads and unloads workpieces and fixtures into the machine.

- Adjusts workpiece positioning and clamps to ensure proper alignment.

2. Tool and Material Handling

Prepares and handles tools and materials, keeping the work area organized and efficient.

- Inspects and maintains cutting tools, ensuring they are sharp and in good condition.

- Orders and stocks raw materials, such as bar stock and cutting fluids.

3. Quality Control

Conducts basic quality checks on finished parts, identifying any deviations from specifications.

- Measures parts using measuring tools, such as calipers and micrometers.

- Reports any defects or irregularities to the operator for further inspection.

4. Machine and Workspace Maintenance

Assists in cleaning and maintaining the boring machine and surrounding workspace.

- Removes chips and debris from the machine and work area.

- Lubricates and greases machine components to prevent wear and tear.

Interview Tips

To prepare for an interview for a Boring Machine Operator Helper position, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry. Research the specific role and its responsibilities, ensuring you understand the company’s expectations.

- Visit the company website and read about their mission, values, and history.

- Review the job description thoroughly, paying attention to the key responsibilities.

2. Highlight Relevant Experience and Skills

Emphasize your experience in manufacturing settings and any specific skills related to boring machine operations. For example, mention if you have worked as a machinist or machine operator.

- Provide specific examples of your attention to detail and precision work.

- Discuss your ability to work in a team environment and take direction from supervisors.

3. Show Enthusiasm and Motivation

Express your interest in the position and the manufacturing industry. Demonstrate your enthusiasm for learning new skills and contributing to the team.

- Share your eagerness to develop your career in manufacturing.

- Explain why you are particularly drawn to the role of a Boring Machine Operator Helper.

4. Ask Thoughtful Questions

During the interview, ask questions that show your engagement and interest in the company and position. This is an opportunity to demonstrate your understanding of the industry and your commitment to the role.

- Ask about the company’s growth plans and their investment in new technologies.

- Inquire about the training and development opportunities available for employees.

5. Follow Up Professionally

After the interview, send a thank-you note to the interviewer expressing your appreciation for their time and consideration. This is an opportunity to reiterate your interest in the position and highlight any additional qualifications you may have.

- Proofread your email carefully for any errors.

- Consider sending a personalized message to each interviewer if there were multiple.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Boring Machine Operator Helper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!