Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Boring Mill Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

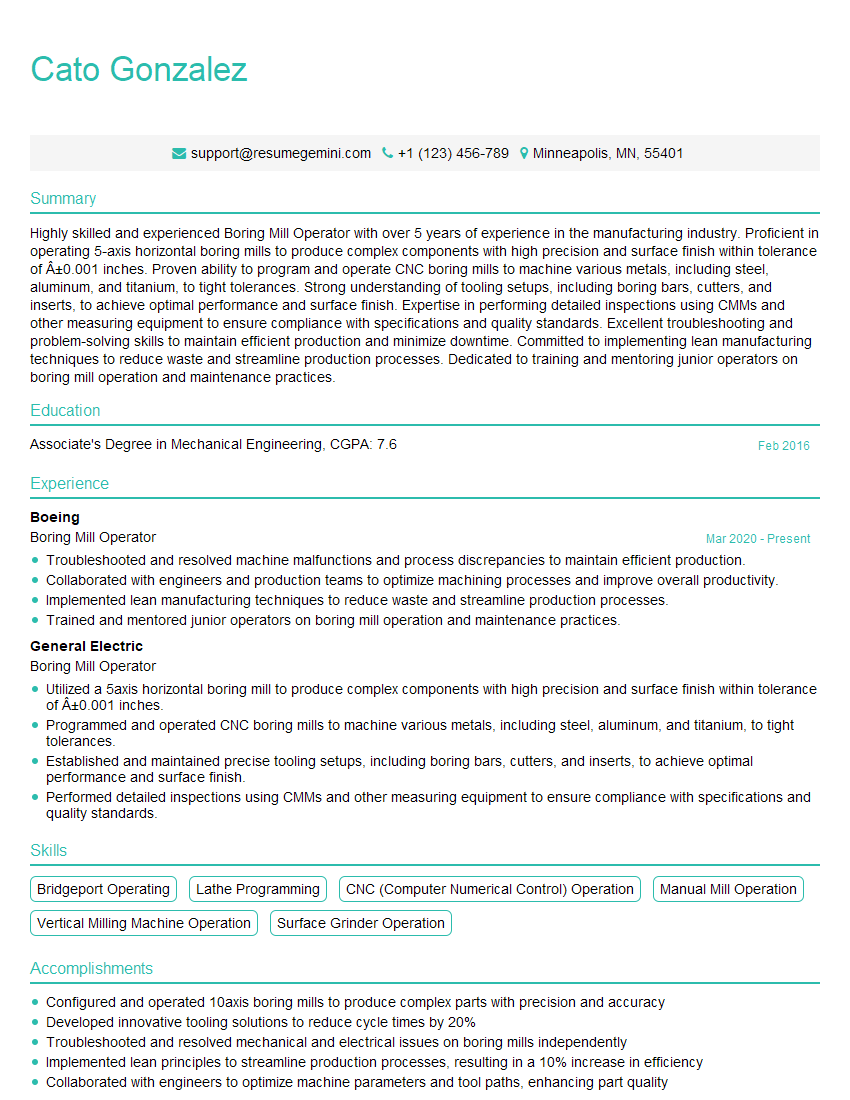

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Boring Mill Operator

1. Describe the critical steps involved in the boring process?

The critical steps involved in the boring process are:

- Understanding and interpreting the workpiece drawing.

- Selecting the appropriate tooling and work holding devices.

- Setting up the machine and aligning the workpiece.

- Establishing the correct spindle speed and feed rate.

- Boring the workpiece to the desired dimensions and tolerances.

- Checking the accuracy of the finished workpiece.

2. What types of cutting tools are used on a boring mill?

Single-point tools

- Boring bars

- Drills

- Reamers

Multi-point tools

- Boring heads

- Facing heads

- Fly cutters

3. How do you ensure that the workpiece is securely held during the boring process?

There are several methods that can be used to securely hold the workpiece during the boring process, including:

- Chucks

- Collets

- Vise

- Clamps

The appropriate method will depend on the size and shape of the workpiece, as well as the specific boring operation being performed.

4. What are the different types of boring machines?

The different types of boring machines include:

- Horizontal boring machines

- Vertical boring machines

- Jig boring machines

- CNC boring machines

5. What is the difference between a boring mill and a lathe?

A boring mill is a machine tool that is used to bore holes in metal. A lathe is a machine tool that is used to turn metal. The main difference between a boring mill and a lathe is the way that the workpiece is held. On a boring mill, the workpiece is held in a chuck or collet, and the cutting tool is moved against the workpiece. On a lathe, the workpiece is held between two centers, and the cutting tool is moved along the workpiece.

6. What are the safety precautions that must be taken when operating a boring mill?

The safety precautions that must be taken when operating a boring mill include:

- Wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs.

- Keeping the work area clean and free of debris.

- Ensuring that the machine is properly guarded.

- Never operating the machine while under the influence of drugs or alcohol.

- Following all manufacturer’s instructions for operating the machine.

7. What are the different types of materials that can be bored?

The different types of materials that can be bored include:

- Metals

- Plastics

- Wood

- Composites

8. What are the different types of finishes that can be achieved with boring?

The different types of finishes that can be achieved with boring include:

- Rough boring

- Semi-finish boring

- Finish boring

- Precision boring

9. What are the advantages of using a boring mill?

The advantages of using a boring mill include:

- High precision and accuracy

- Ability to bore large holes

- Can be used for a variety of operations, including boring, drilling, reaming, and facing

10. What are the disadvantages of using a boring mill?

The disadvantages of using a boring mill include:

- High cost

- Complex to operate

- Requires skilled operators

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Boring Mill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Boring Mill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Boring Mill Operator is responsible for operating and maintaining a boring mill machine, a specialized tool used for creating precise holes and cavities in metal workpieces. Their primary duties include:

1. Machine Operation

Setting up and operating the boring mill machine to perform precise boring, facing, and turning operations on metal workpieces.

2. Workpiece Preparation

Preparing and securing workpieces onto the boring mill table, ensuring proper alignment and stability during machining.

3. Tool Selection and Installation

Selecting and installing appropriate cutting tools, such as boring bars, facing heads, and inserts, based on workpiece specifications and machining requirements.

4. Measurement and Inspection

Using precision measuring instruments to verify the accuracy of workpiece dimensions and surface finishes, ensuring compliance with specified tolerances.

5. Machine Maintenance

Performing routine maintenance tasks on the boring mill machine, including cleaning, lubrication, and minor repairs, to maintain optimal performance.

Interview Tips

To effectively prepare for an interview as a Boring Mill Operator, follow these tips and hacks:

1. Research the Company and Position

Gather information about the company’s industry, products, and culture, as well as the specific requirements and expectations of the Boring Mill Operator role.

2. Highlight Relevant Experience and Skills

In your resume and during the interview, emphasize your experience in operating boring mill machines and your skills in workpiece preparation, tool selection, and measurement.

3. Demonstrate Precision and Attention to Detail

Emphasize your meticulous nature and ability to work with precision, ensuring the accuracy and quality of machined parts.

4. Showcase Problem-Solving Abilities

Provide examples of how you have successfully resolved machine malfunctions or identified and corrected errors in workpiece production.

5. Practice Common Interview Questions

Prepare answers to common interview questions related to your skills, experience, and motivation for pursuing the Boring Mill Operator position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Boring Mill Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.