Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Boring Mill Set Up Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Boring Mill Set Up Operator so you can tailor your answers to impress potential employers.

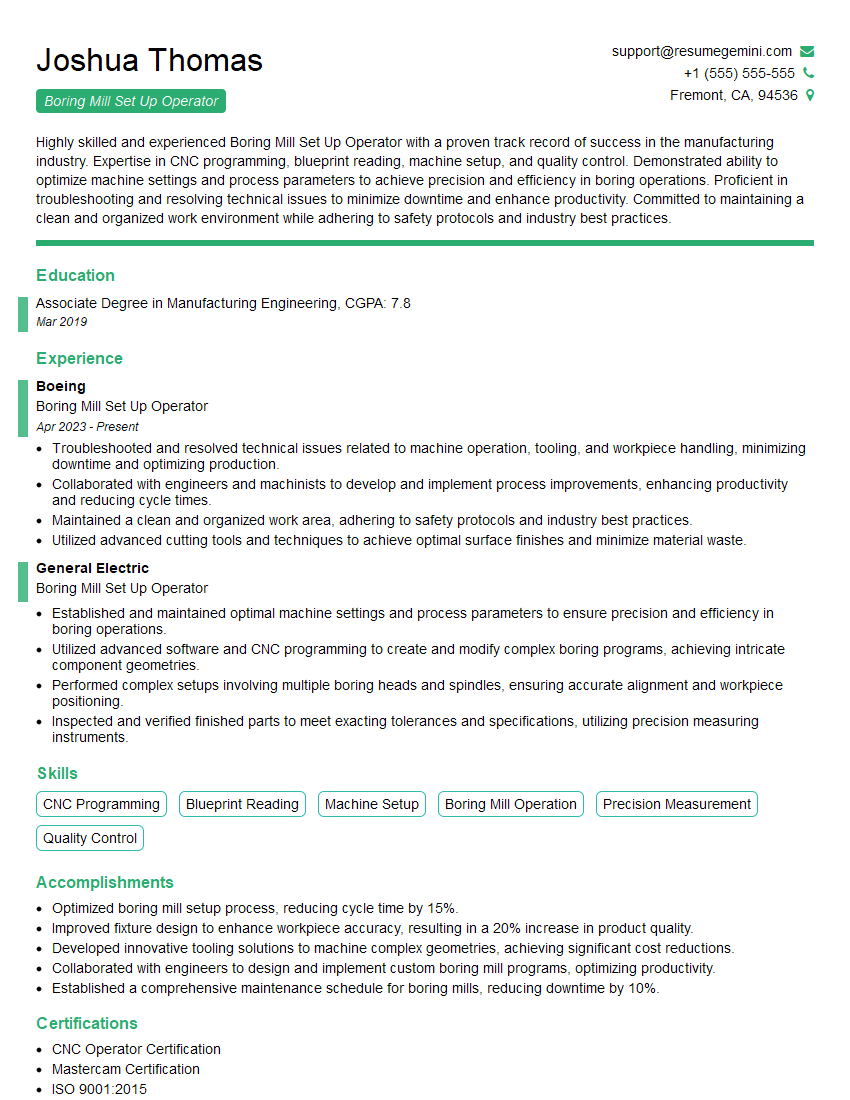

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Boring Mill Set Up Operator

1. Which types of Boring Mills you have operated before? Vertical or Horizontal?

I have worked on both vertical and horizontal boring mills.

2. Define role of Boring Mill Set-Up Operator?

Job Description

- set up and operate a boring mill

- control the movements of the table

- spindle and boring head

- select the correct tooling

- monitor the progress of the machining operation

- make adjustments as needed

- inspect the finished product

Responsibilities

- follow safety procedures

- maintain a clean and organized work area

- troubleshoot any problems that may arise

- work with other members of the production team

3. What skills are required to be a successful Boring Mill Set-Up Operator?

The skills required to be a successful Boring Mill Set-Up Operator include:

- Ability to read and interpret blueprints

- Knowledge of machining processes

- Experience with setting up and operating boring mills

- Strong attention to detail

- Ability to work independently and as part of a team

- Good communication and interpersonal skills

4. How to ensure that the machine table, spindle and other parts are in good condition?

To ensure that the machine table, spindle and other parts are in good condition, I would perform the following checks:

- Inspect the table for any signs of damage or wear

- Check the spindle for any signs of play or vibration

- Inspect the other parts of the machine for any signs of damage or wear

5. Explain “Boring Mill Set-Up”?

Boring Mill Set-Up involves the following steps:

- Mounting the workpiece on the table

- Aligning the workpiece with the spindle

- Selecting the correct tooling

- Setting the feed and speed rates

- Starting the machining operation

6. How to plan, set-up and operate boring mill for high volume component production?

Planning

- Determine the production requirements

- Select the appropriate boring mill

- Order the necessary tooling

- Develop a set-up plan

Set-up

- Mount the workpiece on the table

- Align the workpiece with the spindle

- Select the correct tooling

- Set the feed and speed rates

Operation

- Start the machining operation

- Monitor the progress of the operation

- Make adjustments as needed

- Inspect the finished product

7. How to maintain a boring mill?

To maintain a boring mill, I would perform the following tasks:

- Clean the machine regularly

- Lubricate the moving parts

- Inspect the machine for any signs of damage or wear

- Perform any necessary repairs

8. What safety precautions should be taken when operating a boring mill?

The safety precautions that should be taken when operating a boring mill include:

- Always wear appropriate safety gear

- Never operate the machine if you are tired or under the influence of drugs or alcohol

- Keep your hands away from the moving parts of the machine

- Be aware of the location of the emergency stop button

9. Explain the potential hazards associated with operating a boring mill and how to avoid them?

The potential hazards associated with operating a boring mill include:

- Cuts and lacerations

- Eye injuries

- Repetitive stress injuries

- Noise-induced hearing loss

To avoid these hazards, it is important to take the following precautions:

- Always wear appropriate safety gear

- Never operate the machine if you are tired or under the influence of drugs or alcohol

- Keep your hands away from the moving parts of the machine

- Be aware of the location of the emergency stop button

10. What are some common problems that can occur when operating a boring mill and how to troubleshoot them?

Some common problems that can occur when operating a boring mill include:

- The machine is not cutting properly

- The machine is making excessive noise

- The machine is vibrating excessively

- The machine is overheating

To troubleshoot these problems, it is important to:

- Check the cutting tool

- Check the machine settings

- Check the workpiece

- Check the machine for any signs of damage or wear

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Boring Mill Set Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Boring Mill Set Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Boring Mill Set Up Operators play a crucial role in manufacturing by setting up and operating boring mills to perform precision machining operations. Their primary responsibilities include:

1. Machine Preparation and Setup

Thoroughly studying blueprints and work orders to understand the required machining operations

- Selecting and installing appropriate cutting tools and fixtures

- Establishing machine parameters, including spindle speed, feed rates, and coolant settings

- Performing trial cuts and adjustments to ensure optimal performance

2. Machine Operation

Skilfully operating boring mills to execute machining processes with precision and efficiency

- Monitoring machine operation and adjusting parameters as needed to maintain accuracy

- Inspecting machined parts and verifying their conformance to specifications

- Making necessary adjustments to tools and settings based on inspection results

3. Tool Maintenance

Ensuring that cutting tools are sharp and in good working condition

- Sharpening or replacing dull tools as required

- Inspecting and maintaining tool holders and fixtures

4. Quality Control

Conducting thorough inspections of machined parts to ensure they meet quality standards

- Using precision measuring instruments to verify dimensions and tolerances

- Identifying and correcting any non-conformances

Interview Preparation Tips

To ace the interview for a Boring Mill Set Up Operator position, candidates should:

1. Research the Company and Position

Demonstrating knowledge of the company’s operations and the specific role will show interest and preparation.

- Visit the company website to learn about their products, services, and work culture.

- Carefully review the job description to identify the essential qualifications and responsibilities.

2. Highlight Relevant Skills and Experience

Emphasizing skills and experiences that are directly relevant to the job requirements will increase the chances of a successful interview.

- Quantify accomplishments using specific metrics whenever possible.

- Share examples of successfully setting up and operating boring mills, ensuring precision and quality in machining operations.

3. Prepare for Common Interview Questions

Anticipating common interview questions and preparing well-thought-out answers will demonstrate confidence and professionalism.

- Practice answering questions about experience with different types of boring machines, cutting tools, and quality control techniques.

- Consider questions about safety protocols, problem-solving abilities, and attention to detail.

4. Ask Informed Questions

Asking thoughtful questions during the interview indicates engagement and interest in the position.

- Inquire about the company’s production processes and quality standards.

- Ask about opportunities for professional development and advancement within the company.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Boring Mill Set Up Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Boring Mill Set Up Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.