Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Bottle and Glass Inspector interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Bottle and Glass Inspector so you can tailor your answers to impress potential employers.

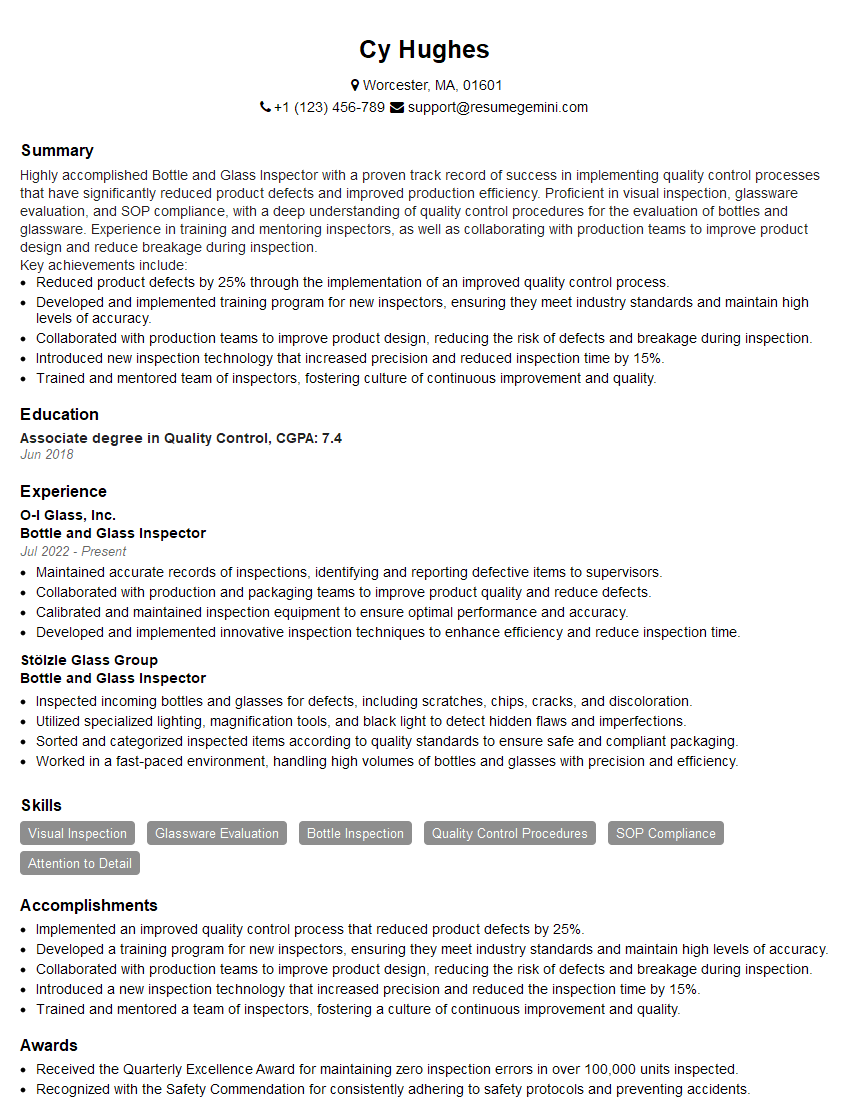

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bottle and Glass Inspector

1. Describe the process of inspecting bottles for defects using an automated inspection machine.

The automated inspection machine utilizes high-resolution cameras and sensors to thoroughly examine each bottle. The machine checks for:

- Structural defects such as cracks, chips, and deformities

- Contaminants like dirt, glass fragments, or foreign objects

- Correct measurements and dimensions

- Color variations or irregularities

2. How do you determine the acceptability of bottles based on inspection results?

: Criteria for Acceptability

- Conformance to established quality standards and specifications

- Absence of any defects or imperfections that could compromise product safety

Subheading: Inspection Outcomes

- Approved: Bottles meet all criteria and are deemed fit for use

- Rejected: Bottles fail to meet criteria and are removed from the production line

- Quarantined: Bottles require further inspection or testing

3. What types of defects are you trained to identify, and how do you classify them based on severity?

I am trained to identify the following types of defects:

- Structural defects: cracks, chips, and deformities

- Cosmetic defects: scratches, scuffs, and discoloration

- Contamination: dirt, glass fragments, and foreign objects

Defects are classified based on severity as follows:

- Critical defects: render the bottle unusable

- Major defects: significantly affect the bottle’s quality

- Minor defects: have minimal impact on the bottle’s functionality

4. How do you ensure consistent and accurate inspection results between different inspectors?

To ensure consistency and accuracy, we follow standardized inspection procedures and utilize:

- Calibration and maintenance of inspection equipment

- Regular training and certification of inspectors

- Double-checking and cross-referencing of inspection results

- Independent audits and quality checks

5. How do you handle situations where defects are identified during the inspection process?

When defects are identified, I follow the following steps:

- Record the type and severity of the defect

- Flag the defective bottles for removal from the production line

- Notify the supervisor or quality control team

- Document the inspection findings and corrective actions taken

6. What are the safety protocols you follow while inspecting bottles?

To ensure safety, I adhere to the following protocols:

- Wearing appropriate personal protective equipment (PPE), such as gloves and safety glasses

- Handling bottles with care to avoid breakage or injury

- Maintaining a clean and organized inspection area

- Following proper ergonomic practices to prevent strain or injury

7. How do you stay up-to-date with advancements in bottle inspection technology?

To stay current with advancements in technology, I:

- Attend industry conferences and training workshops

- Read technical journals and articles on inspection techniques

- Network with other professionals in the field

- Seek opportunities for professional development

8. How do you handle the repetitive nature of the inspection process?

To maintain focus and accuracy during the repetitive inspection process, I:

- Break down the task into smaller, manageable chunks

- Take regular breaks to rest my eyes and mind

- Listen to music or podcasts to stay engaged

- Stay hydrated and maintain a healthy posture

9. How do you contribute to the overall quality control process in the manufacturing facility?

My role as a Bottle and Glass Inspector contributes to the overall quality control process in the following ways:

- Identifying and removing defective bottles from the production line

- Providing feedback to the production team to improve product quality

- Participating in quality improvement initiatives and programs

- Maintaining accurate records and documentation

10. What are your expectations for this role, and how do you plan to add value to our team?

As a Bottle and Glass Inspector, I expect to:

- Contribute to maintaining a high level of product quality

- Work diligently and efficiently to meet production targets

- Collaborate with the team to resolve issues and improve processes

- Stay informed about industry best practices and advancements

I believe I can add value to the team through:

- My technical skills and experience in bottle inspection

- My attention to detail and commitment to quality

- My ability to work independently and as part of a team

- My willingness to learn and grow professionally

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bottle and Glass Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bottle and Glass Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bottle and Glass Inspectors perform visual inspections of containers like bottles and jars to ensure they meet quality and safety standards. Let’s explore their crucial responsibilities in detail:

1. Inspect Containers for Defects

Inspectors meticulously examine containers for cracks, chips, scratches, dents, and other imperfections. They utilize specialized equipment, such as magnifying glasses and strobe lights, to detect even the smallest flaws.

- Identify and mark defective containers clearly.

- Document the type and severity of defects for corrective actions.

2. Check for Glass Thickness and Clarity

Ensuring the structural integrity and visual clarity of containers is paramount. Inspectors measure glass thickness and inspect for bubbles, inclusions, and other anomalies using industry-standard gauges and optical devices.

- Calibrate and operate thickness gauges accurately.

- Inspect containers for any abnormalities that affect clarity and light transmission.

3. Verify Labeling and Packaging

Inspectors inspect labels for proper placement, adherence, and accuracy of information. They also verify that containers are packaged correctly to provide protection during storage and transportation.

- Ensure labels meet regulatory requirements and convey necessary information clearly.

- Inspect packaging materials for damage, contamination, or inadequate protection.

4. Maintain Quality Records

Inspectors document inspection findings meticulously and maintain accurate records. These records assist in identifying trends, improving processes, and ensuring traceability in case of recalls.

- Record inspection data accurately and consistently.

- Maintain organized records for easy retrieval and analysis.

Interview Tips

To ace the Bottle and Glass Inspector interview, thorough preparation is the key. Here are some essential tips to help you succeed:

1. Research the Company and Industry

Demonstrate your interest and understanding of the company’s business, product line, and industry trends. This shows that you are invested in the role and have a genuine curiosity about the field.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay informed about current practices.

2. Highlight Relevant Experience and Skills

Emphasize your prior experience in quality control, inspection, or manufacturing. Quantify your accomplishments and use specific examples to showcase your attention to detail, problem-solving abilities, and commitment to accuracy.

- Describe previous tasks involving visual inspection of products.

- Mention the use of inspection equipment and calibration procedures.

3. Show Enthusiasm and Attention to Detail

During the interview, convey your passion for quality and your meticulous nature. Let the interviewer know that you are eager to contribute to the company’s mission of providing safe and reliable products.

- Express your understanding of the importance of product safety.

- Share examples where your attention to detail helped prevent potential issues.

4. Prepare Answers to Common Questions

Anticipate questions about your experience, qualifications, and motivation for the role. Practice your answers beforehand to ensure they are concise, relevant, and highlight your strengths.

- Prepare to discuss your understanding of quality control principles.

- Be ready to provide examples of your problem-solving abilities in a manufacturing environment.

5. Ask Thoughtful Questions

Asking insightful questions demonstrates your interest in the position and the company. It also gives you an opportunity to clarify any doubts and show that you are engaged in the process.

- Inquire about the company’s quality control procedures.

- Ask about opportunities for professional development within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bottle and Glass Inspector interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!