Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Bottle Gauger position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

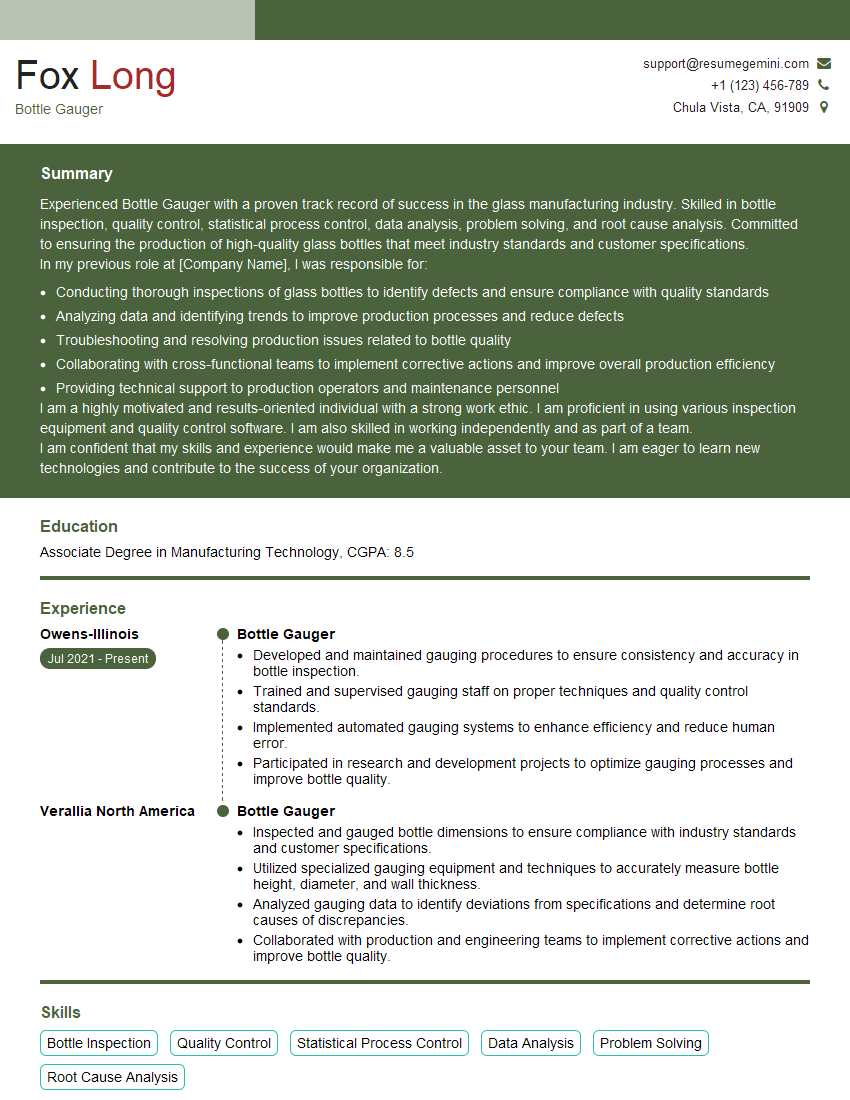

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bottle Gauger

1. What are the different types of bottle gauges and their uses?

- Surface Gauges: Measuring the radius of cylindrical surfaces.

- Taper Gauges: Determining the taper or angle of conical surfaces.

- Ring Gauges: Checking the diameter and roundness of cylindrical holes.

- Plug Gauges: Inspecting the diameter and cylindrical shape of internal surfaces.

- Thread Gauges: Evaluating the pitch, diameter, and shape of threads.

2. Explain the process of calibrating a bottle gauge.

Zeroing the Gauge

- Secure the gauge in a calibration fixture.

- Align the measuring face with a reference surface.

- Adjust the dial or digital readout to zero.

Checking Accuracy

- Use traceable gauge blocks or master standards.

- Measure the known dimension and compare it to the gauge reading.

- Adjust the gauge if necessary to ensure accuracy.

3. What are the common sources of error when using a bottle gauge?

- Incorrect calibration or wear on the gauge itself.

- Misalignment of the gauge with the surface being measured.

- Temperature variations affecting the thermal expansion of the gauge or workpiece.

- Operator error, such as improper handling or incorrect interpretation of readings.

- Contamination on the surface being measured or the gauge tip.

4. What are the factors to consider when selecting the appropriate bottle gauge for a specific application?

- Type of measurement required (diameter, taper, etc.).

- Size and accessibility of the area being measured.

- Desired accuracy and precision levels.

- Material and surface finish of the workpiece.

- Environmental conditions where the gauge will be used.

5. Explain how to use a bottle gauge to measure the diameter of a cylindrical workpiece.

- Calibrate the gauge before use.

- Hold the workpiece vertically.

- Align the gauge perpendicular to the workpiece.

- Gently contact the workpiece with the gauge tip.

- Record the reading on the dial or digital display.

6. What is the difference between a fixed and an adjustable bottle gauge?

- Fixed Gauges: Have a predetermined measurement range and cannot be adjusted.

- Adjustable Gauges: Allow for fine-tuning of the measurement range within specified limits.

7. What materials are typically used in the construction of bottle gauges?

- Hardened Steel: Provides durability and wear resistance.

- Tungsten Carbide: Offers exceptional hardness and abrasion resistance.

- Ceramic: Used for high-precision measurements, resistant to wear and corrosion.

- Composite Materials: Combining different materials for specific performance characteristics.

8. Describe the different readout systems commonly found on bottle gauges.

- Dial Gauges: Analog display with a rotating pointer and graduated scale.

- Digital Gauges: Electronic display showing the measured value directly in numerical format.

- LCD Gauges: Liquid crystal display providing high-resolution and customizable readouts.

- Laser Gauges: Non-contact measurement, using a laser beam to determine dimensions.

9. What are some best practices for maintaining the accuracy of bottle gauges?

- Regular calibration using traceable standards.

- Proper storage and handling to prevent damage.

- Cleaning and lubrication of moving parts as recommended.

- Using the gauge within its specified measurement range.

- Avoiding exposure to extreme temperatures or corrosive environments.

10. Explain how bottle gauges contribute to quality control in manufacturing processes.

- Ensuring dimensional accuracy of components and products.

- Preventing defective parts from entering production lines.

- Monitoring and maintaining process stability.

- Reducing scrap and rework costs.

- Complying with quality standards and regulations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bottle Gauger.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bottle Gauger‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Bottle Gauger is responsible for ensuring the accuracy and consistency of the filling process in a beverage production facility. They utilize specialized equipment to measure and verify the volume of liquid filled into bottles, ensuring compliance with industry standards and customer specifications.

1. Bottle Volume Measurement and Verification

Utilizes sophisticated gauging equipment to accurately measure the volume of liquid filled into bottles.

- Calibrates and maintains gauging equipment to ensure precision and accuracy.

- Inspects bottles for defects or abnormalities that may affect volume measurement.

2. Quality Control and Process Monitoring

Monitors the filling process to ensure it adheres to established quality standards and customer requirements.

- Inspects filled bottles for proper fill levels, headspace, and seal integrity.

- Conducts statistical process control (SPC) to identify and minimize variation in filling volumes.

3. Data Analysis and Reporting

Collects and analyzes data related to bottle volumes and filling process performance.

- Generates reports on volume measurement results, equipment performance, and process deviations.

- Identifies trends and patterns in data to improve filling accuracy and efficiency.

4. Troubleshooting and Maintenance

Troubleshoots and resolves issues related to bottle gauging equipment and the filling process.

- Performs routine maintenance and repairs on gauging equipment to ensure optimal operation.

- Collaborates with production and maintenance teams to identify and address root causes of filling process deviations.

Interview Tips

Preparing thoroughly for a Bottle Gauger interview can significantly increase your chances of success. Here are some key tips and hacks to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s background, products, and industry reputation. This will enable you to tailor your answers to the specific requirements of the role and demonstrate your interest in the company.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay updated on the latest trends.

2. Highlight Your Technical Skills

Emphasize your proficiency in using bottle gauging equipment and your understanding of quality control principles. Provide specific examples of your experience in these areas.

- Quantify your accomplishments whenever possible, using specific metrics.

- Use technical terms and concepts to demonstrate your expertise.

3. Showcase Your Problem-Solving Abilities

Interviewers will be interested in your ability to identify and resolve issues related to bottle gauging and the filling process. Share examples of how you have successfully solved problems in the past.

- Use the STAR method to structure your answers:

- Situation: Describe the situation or problem you encountered.

- Task: Explain the task you needed to accomplish.

- Action: Outline the specific actions you took to solve the problem.

- Result: Describe the positive outcomes of your actions.

4. Prepare for Common Interview Questions

Familiarize yourself with common interview questions related to bottle gauging and the filling process. This will help you prepare thoughtful and concise answers that showcase your knowledge and skills.

- Common questions include:

- Tell me about your experience in using bottle gauging equipment.

- How do you ensure the accuracy and consistency of filling volumes?

- What steps do you take to troubleshoot and resolve issues related to the filling process?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bottle Gauger interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.