Feeling lost in a sea of interview questions? Landed that dream interview for Bottle Inspector but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Bottle Inspector interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

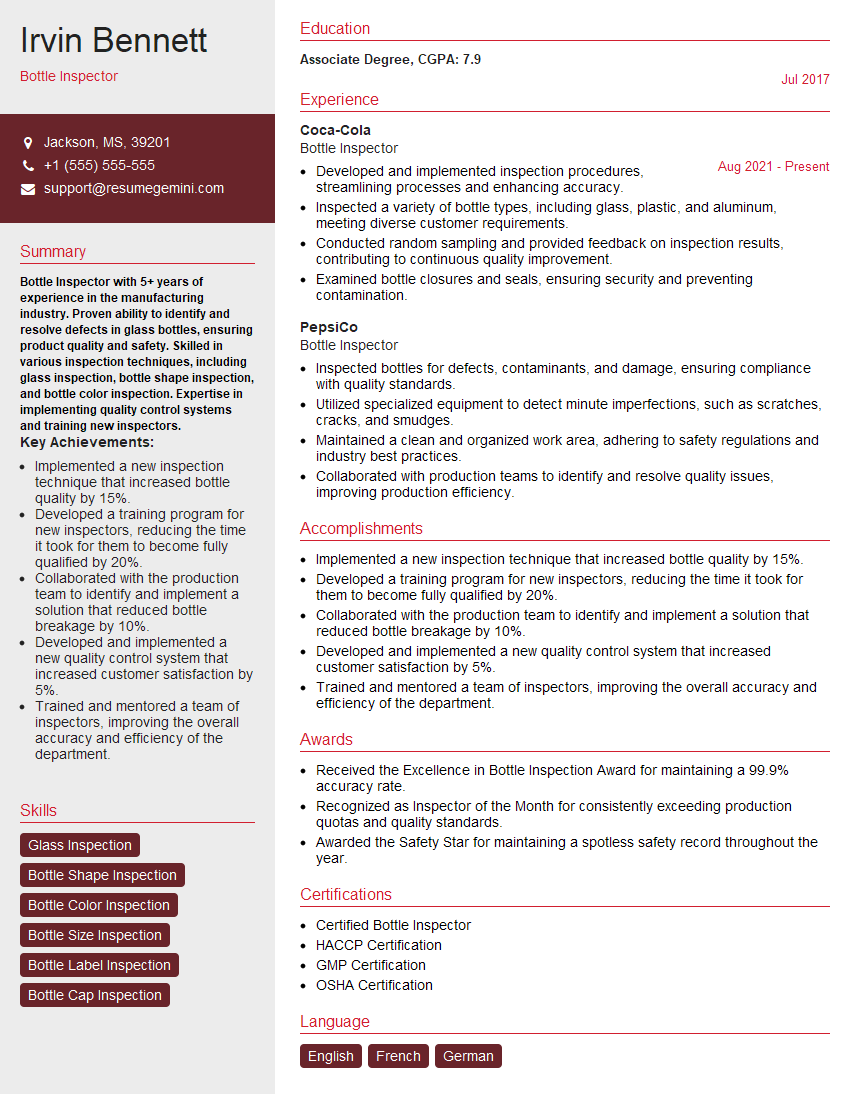

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bottle Inspector

1. What are the different types of bottle defects that you inspect for?

In my previous role, I was responsible for inspecting bottles for various defects, including:

- Scratches and abrasions on the glass surface

- Chips or cracks in the glass

- Uneven or distorted bottle shapes

- Incorrect or missing labels

- Foreign objects or contaminants inside the bottles

2. What is your preferred method for inspecting bottles?

Visual inspection

- I use my highly trained eye to carefully examine each bottle for any visible defects.

- I ensure proper lighting conditions to enhance visibility and minimize errors.

Automated inspection

- I am also proficient in using automated inspection machines.

- These machines use advanced sensors and cameras to detect defects that may be difficult to spot manually.

3. How do you ensure the accuracy of your inspections?

I prioritize accuracy in my inspections by:

- Maintaining a high level of concentration and attention to detail.

- Regularly calibrating and maintaining my inspection equipment.

- Following standardized inspection procedures to minimize errors.

- Consulting with other inspectors or supervisors to verify my findings.

4. What is your record-keeping process for defects you identify?

I meticulously document all defects identified during my inspections:

- I create detailed reports that include the type of defect, location, and severity.

- I use a computerized database to store and manage these records.

- I regularly review and analyze the inspection data to identify trends and areas for improvement.

5. How do you prioritize which bottles to inspect first?

I prioritize my inspections based on various factors:

- Bottle type: Certain bottle types, such as those used for pharmaceutical products, require more rigorous inspection.

- Production stage: Bottles at different stages of production may have different defect profiles.

- Time constraints: I allocate more time to inspect bottles with a higher risk of defects.

- Customer specifications: I prioritize inspections based on specific customer requirements.

6. Describe a situation where you identified a critical defect that could have had serious consequences.

In a previous inspection, I detected a subtle crack in a glass bottle intended for a carbonated beverage.

- I immediately quarantined the bottle and reported my findings to the production supervisor.

- This timely intervention prevented the defective bottle from reaching consumers, potentially avoiding serious safety hazards.

7. How do you stay updated on the latest inspection techniques and industry standards?

I actively pursue continuous learning to enhance my inspection skills:

- I attend industry conferences and workshops.

- I read technical literature and online resources.

- I network with other inspectors and experts in the field.

8. How do you handle situations where you encounter a defect that you are unsure about?

When faced with an uncertain defect:

- I consult with more experienced inspectors or supervisors for their insights.

- I seek additional training or resources to enhance my knowledge.

- I document the defect and quarantine the affected bottles until a clear determination can be made.

9. What are your strengths and weaknesses as a Bottle Inspector?

Strengths:

- Exceptional attention to detail and accuracy.

- Expertise in identifying various bottle defects.

- Strong analytical and problem-solving skills.

Weaknesses:

- Can be susceptible to fatigue during extended inspection sessions (Working on improving endurance).

10. Why are you interested in this Bottle Inspector position at our company?

I am eager to contribute my skills and experience to your esteemed organization.

- Your company’s reputation for quality and safety aligns with my values.

- I believe that my knowledge of bottle inspection can enhance your production processes.

- I am confident that I can add value to your team and contribute to the success of your operations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bottle Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bottle Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bottle Inspectors examine and inspect empty bottles, containers, and jars for defects, ensuring that these are clean and free from any impurities before they are filled with consumable products.

1. Visual Examination

Physically examine bottles for any visible defects such as chips, cracks, scratches, or other imperfections that may compromise the integrity or cleanliness of the container.

- Inspect bottles using a variety of methods, including manual visual inspection, automated equipment, or a combination of both.

- Pay attention to the color, clarity, and shape of the bottles to ensure they meet quality standards.

2. Sanitation and Hygiene

Ensure that bottles and containers are thoroughly cleaned and sanitized before filling. This may involve using specialized equipment or following established sanitation protocols.

- Follow strict hygiene practices to prevent contamination of products.

- Monitor the cleanliness of the production area and equipment to maintain a hygienic work environment.

3. Documentation and Reporting

Record and document inspection results, including any defects or issues identified during the inspection process. This may involve maintaining inspection logs or using automated systems.

- Accurately record data related to bottle quality, defects, and production.

- Report any deviations from standard operating procedures or quality specifications to supervisors.

4. Quality Control

Adhere to established quality control standards and procedures to ensure the accuracy and consistency of the inspection process.

- Participate in quality control programs and initiatives to maintain high standards.

- Work closely with other quality control personnel to identify and address any potential issues.

Interview Tips

Preparing for a job interview can be a daunting task. However, with the right strategies and a little bit of effort, you can increase your chances of success and ace the interview.

1. Research the Company and Position

Take the time to thoroughly research the company and the specific position you are applying for. This will demonstrate your interest in the opportunity and show the interviewer that you are serious about the role.

- Visit the company’s website and social media pages to learn about their mission, values, and recent projects.

- Read industry news and articles to stay up-to-date on the latest trends and developments in the field.

2. Practice and Prepare Your Answers

Practice your answers to common interview questions and prepare specific examples that highlight your skills and experience. This will help you feel more confident and prepared during the interview.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide concise and impactful examples.

- Consider the key job responsibilities for the position and prepare examples that demonstrate your proficiency in those areas.

3. Dress Professionally and Arrive on Time

First impressions matter. Dress appropriately for the interview and arrive on time to show the interviewer that you are respectful of their time.

- Choose clothing that is clean, pressed, and appropriate for the industry and company culture.

- Plan your route and give yourself ample time to get to the interview location, accounting for potential delays.

4. Be Enthusiastic and Positive

Convey your enthusiasm for the position and the opportunity to work for the company. A positive attitude and a willingness to learn will make a lasting impression.

- Smile, make eye contact, and engage with the interviewer in a friendly and professional manner.

- Highlight your passion for quality control and your commitment to maintaining high standards.

5. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview demonstrates your interest in the position and the company. This is also an opportunity to clarify any details and show that you are engaged in the conversation.

- Prepare a list of well-thought-out questions related to the role, the company, or the industry.

- Avoid asking questions that are easily answered by the job description or company website.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Bottle Inspector, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Bottle Inspector positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.