Are you gearing up for an interview for a Bottle Labeler position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Bottle Labeler and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

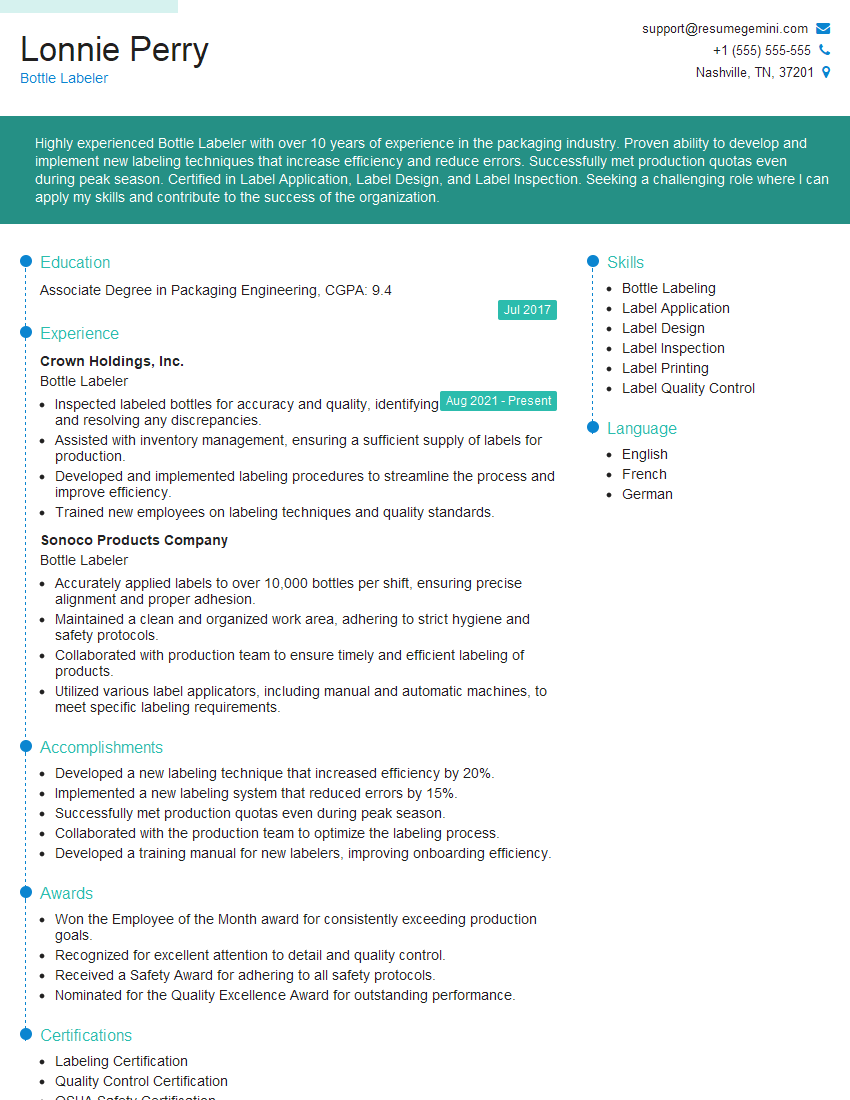

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bottle Labeler

1. Explain the process of applying labels to bottles using a bottle labeling machine?

- Remove any existing labels from the bottles.

- Inspect the bottles for any damage or contamination.

- Load the bottles into the labeling machine.

- Set the machine’s parameters, such as the label speed and tension.

- Start the labeling process.

- Inspect the labeled bottles for any defects.

- Unload the labeled bottles from the machine.

2. What are the different types of bottle labeling machines?

Rotary Labeling Machine

- High-speed labeling.

- Suitable for various bottle shapes and sizes.

Inline Labeling Machine

- Labels bottles as they move through the machine.

- Ideal for high-volume production lines.

Shrink Sleeve Labeling Machine

- Applies a heat-shrinkable sleeve to the bottle.

- Creates a tamper-evident and attractive label.

3. What are the common problems that can occur during bottle labeling?

- Wrinkled or misaligned labels

- Bubbles or creases in the labels

- Labels peeling off the bottles

- Label jams in the machine

4. How do you troubleshoot a bottle labeling machine?

- Check the machine’s settings and ensure they are correct.

- Inspect the labels and bottles for any defects.

- Clean the machine’s labeling head and other components.

- Lubricate the machine’s moving parts.

- Refer to the machine’s manual for specific troubleshooting tips.

5. What are the safety precautions that should be taken when operating a bottle labeling machine?

- Wear appropriate safety gear, including gloves and safety glasses.

- Keep the work area clean and free of debris.

- Be aware of the machine’s moving parts and avoid contact.

- Follow the machine’s operating instructions carefully.

- Report any malfunctions or accidents to the supervisor immediately.

6. What are the different types of labels that can be applied to bottles?

- Paper labels

- Plastic labels

- Shrink sleeve labels

- Pressure-sensitive labels

- In-mold labels

7. What factors should be considered when choosing a bottle labeling machine?

- The type of bottles being labeled

- The speed of the labeling process

- The accuracy of the labeling

- The cost of the machine

- The availability of maintenance and support

8. What are the different types of label applicators?

- Wipe-on label applicators

- Roll-on label applicators

- Pressure-sensitive label applicators

- Automatic label applicators

9. What are the advantages and disadvantages of using a bottle labeling machine?

Advantages:

- Increased labeling speed and efficiency

- Improved label quality and accuracy

- Reduced labor costs

- Increased production capacity

Disadvantages:

- Upfront cost of the machine

- Complexity of the machine

- Maintenance and repair costs

10. What are the latest trends in bottle labeling technology?

- Increased use of automation

- Development of more efficient and accurate labeling machines

- Increased use of sustainable and eco-friendly labeling materials

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bottle Labeler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bottle Labeler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bottle Labelers are responsible for ensuring that bottles are labeled correctly and efficiently. Their duties include:

1. Preparing Bottles for Labeling

Bottle Labelers must first prepare bottles for labeling. This includes checking the bottles for damage, removing any existing labels, and applying adhesive to the bottles.

- Inspecting bottles for defects or damage

- Removing old labels or adhesive residue

- Applying adhesive to bottles using a brush or roller

2. Labeling Bottles

Once the bottles are prepared, Bottle Labelers must apply labels to them. This involves carefully aligning the labels with the bottles and pressing them down to ensure they adhere properly.

- Selecting the correct label for each bottle

- Aligning labels with bottles and applying pressure

- Inspecting labeled bottles for accuracy and quality

3. Inspecting Labeled Bottles

After the bottles are labeled, Bottle Labelers must inspect them to ensure that the labels are applied correctly and that there are no defects. This may involve checking for wrinkles, tears, or misalignments.

- Checking labels for wrinkles, tears, or misalignments

- Inspecting bottles for proper adhesion and legibility

- Rejecting bottles with defective labels

4. Maintaining Equipment

Bottle Labelers are also responsible for maintaining the equipment they use, which may include label applicators, conveyors, and other machinery. This involves cleaning, lubricating, and making minor repairs as needed.

- Cleaning and lubricating label applicators and conveyors

- Performing basic maintenance and repairs on equipment

- Reporting any equipment problems to supervisors

Interview Tips

Preparing for an interview for a Bottle Labeler position can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, and it will also help you tailor your answers to the interviewer’s questions.

- Visit the company’s website and social media pages

- Read industry publications and news articles

- Talk to people who work at the company, if possible

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, regardless of the position you are applying for. It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and clearly.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What are your salary expectations?

3. Prepare Questions to Ask the Interviewer

Asking questions at the end of an interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the company and the role you would be playing. Some good questions to ask include:

- What are the biggest challenges facing the company right now?

- What are the company’s goals for the next year?

- What is the company culture like?

4. Dress Professionally and Be Punctual

First impressions matter, so it is important to dress professionally for your interview. You should also be punctual and arrive on time for your interview. This shows that you are respectful of the interviewer’s time and that you are serious about the position.

- Wear a suit or business casual attire

- Make sure your clothes are clean and pressed

- Arrive for your interview on time

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bottle Labeler interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.