Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Bottle Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Bottle Machine Operator so you can tailor your answers to impress potential employers.

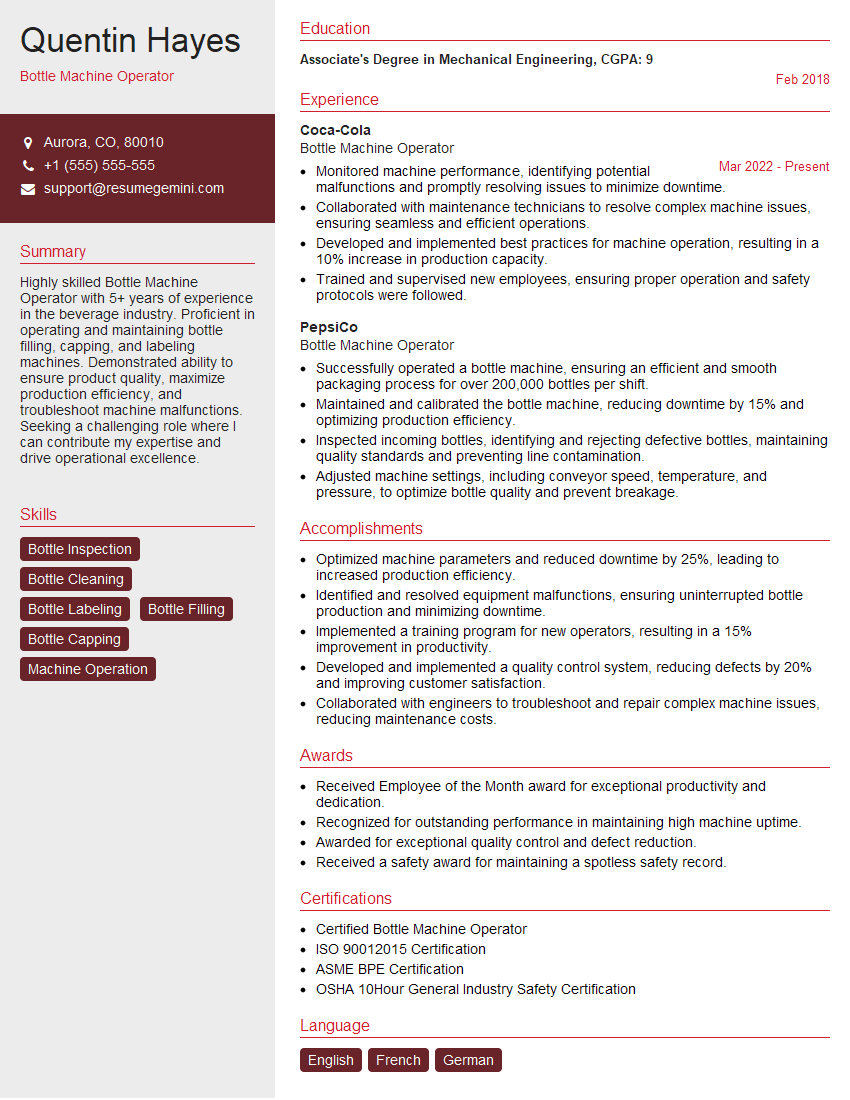

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bottle Machine Operator

1. Describe the process of setting up and operating a bottle filling machine.

In setting up the bottle filling machine, I would first ensure that the machine is properly installed and leveled. I would then inspect all the machine’s components, including the conveyor belt, filling nozzles, and capping system, to make sure they are in good working order.

Once the machine is set up, I would calibrate the filling nozzles to ensure that the bottles are being filled to the correct level. I would also adjust the conveyor belt speed to ensure that the bottles are moving through the machine at the correct rate.

To operate the machine, I would simply load the bottles onto the conveyor belt and start the machine. The machine would then automatically fill and cap the bottles and discharge them onto a discharge conveyor.

2. How do you troubleshoot and resolve common problems with bottle filling machines?

Mechanical Problems

- Inspect the machine for any loose or damaged parts.

- Check the conveyor belt for any tears or blockages.

- Check the filling nozzles for any clogs.

Electrical Problems

- Check the power supply to the machine.

- Check the electrical connections to the machine.

- Check the fuses and circuit breakers.

Software Problems

- Check the software settings to make sure they are correct.

- Restart the software.

- Contact the software manufacturer for support.

3. What are the safety procedures that you follow when operating a bottle filling machine?

- Wear appropriate safety gear, such as gloves and safety glasses.

- Keep the work area clean and free of debris.

- Do not operate the machine if it is not properly maintained.

- Follow all lockout/tagout procedures before performing maintenance on the machine.

- Report any accidents or injuries to your supervisor immediately.

4. What is your experience with maintaining and repairing bottle filling machines?

I have over 5 years of experience maintaining and repairing bottle filling machines. In my previous role, I was responsible for the maintenance and repair of a fleet of bottle filling machines used to fill and cap a variety of different types of bottles.

My duties included:

- Inspecting machines for wear and tear.

- Replacing worn or damaged parts.

- Calibrating machines to ensure accuracy.

- Troubleshooting and resolving mechanical, electrical, and software problems.

5. What are the different types of bottle filling machines that you are familiar with?

- Rotary filling machines

- In-line filling machines

- Gravity filling machines

- Volumetric filling machines

- Overflow filling machines

Each type of filling machine has its own advantages and disadvantages. The best type of filling machine for a particular application will depend on the specific requirements of the application.

6. What are the different types of bottles that you have experience filling?

- Glass bottles

- Plastic bottles

- Metal bottles

Each type of bottle has its own unique characteristics that must be taken into account when filling it. For example, glass bottles are more fragile than plastic bottles, so they must be handled with care.

7. What is the difference between a bottle filler and a bottle capper?

A bottle filler is a machine that fills bottles with liquid. A bottle capper is a machine that caps bottles after they have been filled.

Bottle fillers and cappers can be either manual or automatic. Manual machines require an operator to load and unload the bottles. Automatic machines can be loaded and unloaded automatically.

8. What are the different types of bottle caps that you are familiar with?

- Crown caps

- Lug caps

- Roll-on caps

- Snap-on caps

Each type of bottle cap has its own advantages and disadvantages. The best type of bottle cap for a particular application will depend on the specific requirements of the application.

9. What are the different types of materials that bottles can be made of?

- Glass

- Plastic

- Metal

Each type of material has its own advantages and disadvantages. The best type of material for a particular application will depend on the specific requirements of the application.

10. What are the different types of liquids that can be filled into bottles?

- Water

- Juice

- Soda

- Beer

- Wine

- Spirits

Each type of liquid has its own unique characteristics that must be taken into account when filling it.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bottle Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bottle Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Bottle Machine Operator is responsible for the smooth functioning of the bottle filling and packaging line. The role encompasses a wide range of duties, including:

1. Operating the Bottle Filling Machine

The operator ensures the machine is set up correctly, loads bottles into the feed hopper, and starts the filling process. They monitor the machine’s operation, making adjustments as needed to maintain optimal filling levels, cap tightness, and product quality.

- Loading bottles into the feed hopper

- Starting the filling process

- Monitoring the machine’s operation

- Making adjustments to maintain optimal filling levels, cap tightness, and product quality

2. Inspecting Filled Bottles

After filling, the operator inspects the bottles for any defects, such as cracks, chips, or leaks. They also check the fill levels and cap tightness to ensure they meet quality standards.

- Inspecting filled bottles for defects

- Checking fill levels and cap tightness

- Removing defective bottles from the line

3. Packaging Bottles

The operator loads the filled bottles into packaging materials, such as boxes or crates. They ensure the bottles are packed securely to prevent damage during transport.

- Loading filled bottles into packaging materials

- Ensuring bottles are packed securely

- Labeling and stacking packaged bottles

4. Maintaining Equipment

The operator is responsible for the upkeep of the bottle filling and packaging equipment. They perform routine cleaning, lubrication, and minor repairs to ensure the line runs smoothly.

- Performing routine cleaning, lubrication, and minor repairs

- Reporting major equipment issues to supervisors

- Maintaining a clean and organized work area

Interview Tips

Preparing for a Bottle Machine Operator interview requires thorough research and careful consideration of the key responsibilities. Here are some essential tips to help candidates ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry trends. This knowledge demonstrates your genuine interest in the position and the company’s operations.

- Visit the company’s website

- Read industry news and articles

- Connect with current or former employees on LinkedIn

2. Highlight Relevant Experience and Skills

Emphasize your previous experience in bottle filling and packaging operations. Showcase your technical skills, such as machine operation, quality control, and maintenance. If you have experience in a similar industry, highlight the transferable skills you possess.

- Quantify your accomplishments using specific metrics

- Provide examples of how you improved efficiency or resolved production issues

- Demonstrate your attention to detail and commitment to quality

3. Practice Answering Common Interview Questions

Prepare for common interview questions by practicing your responses. This will help you articulate your qualifications and experience confidently. Anticipate questions about your technical skills, problem-solving abilities, and work ethic.

- Use the STAR method to structure your answers

- Provide clear and concise examples

- Tailor your answers to the specific job requirements

4. Ask Thoughtful Questions

By asking thoughtful questions, you show that you are engaged in the interview process and eager to learn more about the position and the company. Prepare questions about the company’s culture, growth opportunities, and safety procedures.

- Ask about the company’s environmental sustainability initiatives

- Inquire about opportunities for professional development

- Show interest in the company’s safety record and protocols

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bottle Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.