Feeling lost in a sea of interview questions? Landed that dream interview for Bottle Washing Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Bottle Washing Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

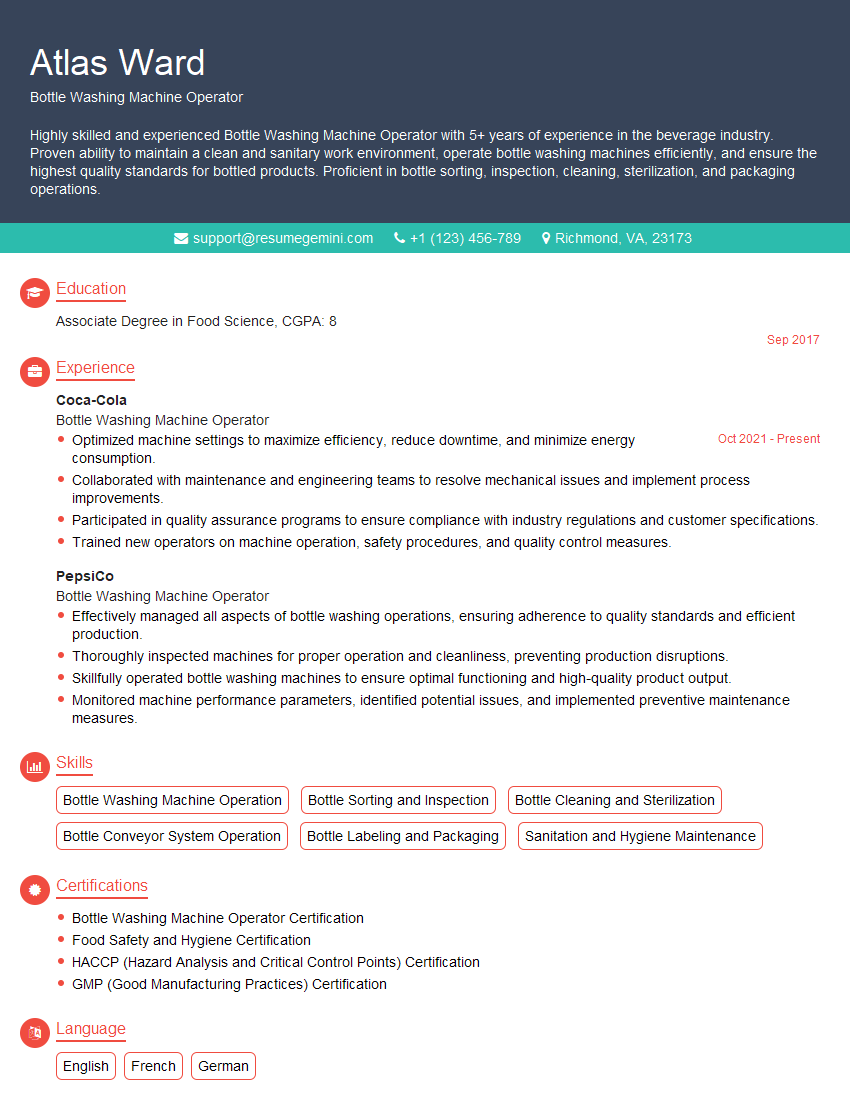

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bottle Washing Machine Operator

1. What are the critical safety measures to be followed while operating a bottle washing machine?

- Always wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and earplugs, to prevent injuries from chemicals, flying glass, or loud noises.

- Ensure the machine is properly grounded to prevent electrical shock.

- Never reach into the machine while it is running to prevent entanglement or injury from moving parts.

- Inspect the machine regularly for any damage or leaks, and report any issues promptly to ensure safe operation.

- Follow all manufacturer’s instructions and safety guidelines to prevent accidents or machine malfunctions.

2. Describe the steps involved in setting up and calibrating a bottle washing machine.

Pre-Setup

- Read the manufacturer’s instructions carefully to understand the setup process.

- Gather necessary tools and equipment, such as wrenches, screwdrivers, and cleaning agents.

- Ensure the machine is placed on a level surface and connected to the appropriate power supply.

Setup

- Assemble the machine according to the manufacturer’s instructions, ensuring all components are securely fastened.

- Connect the water and drain lines to the machine, ensuring they are properly sealed to prevent leaks.

- Fill the chemical tanks with the appropriate cleaning agents and adjust the concentrations as per manufacturer’s specifications.

Calibration

- Run a series of test bottles through the machine to check the wash quality and adjust the settings accordingly.

- Use a pH meter to verify the cleaning agent concentrations and adjust them to the optimal level.

- Calibrate the temperature sensors to ensure the water temperature is within the specified range.

3. Explain the principles of operation of a bottle washing machine.

- Soaking: Bottles are submerged in a cleaning solution to loosen dirt and contaminants.

- Washing: High-pressure jets of water or cleaning solution are used to remove loose contaminants.

- Rinsing: Bottles are rinsed multiple times with clean water to remove residual chemicals.

- Sterilization: Bottles are exposed to a sanitizing agent, such as hot water or chemicals, to kill microorganisms.

- Drying: Bottles are blown dry using hot air or forced air to remove moisture.

4. What are the different types of bottle washing machines and their specific applications?

- Single-End Machines: Designed for low to medium volume operations, these machines wash bottles one at a time.

- Rotary Machines: Ideal for high-volume production, these machines continuously rotate bottles through the washing process.

- Tunnel Machines: Suitable for large-scale operations, these machines convey bottles through a series of wash zones on a conveyor belt.

- In-Line Machines: Integrated into a production line, these machines automatically wash bottles before filling.

- Specialty Machines: Designed for specific applications, such as washing bottles with unique shapes or sizes.

5. Describe the maintenance procedures required for a bottle washing machine.

- Daily: Clean filters, inspect nozzles, and check chemical levels.

- Weekly: Calibrate temperature sensors, lubricate moving parts, and inspect seals and gaskets.

- Monthly: Deep clean the machine using specialized detergents, replace worn nozzles, and check electrical connections.

- Annually: Schedule a comprehensive inspection by a qualified technician to assess overall machine health and identify any potential issues.

6. How do you troubleshoot common problems encountered with bottle washing machines?

- Bottle breakage: Check for worn nozzles, improper water pressure, or excessive chemical concentration.

- Poor wash quality: Inspect nozzles for blockage, adjust chemical concentrations, or increase wash time.

- Leaking: Tighten loose connections, replace worn seals or gaskets, or inspect water lines for damage.

- Machine not starting: Check power supply, inspect electrical connections, or consult the manufacturer’s manual for specific troubleshooting steps.

- Excessive noise or vibration: Lubricate moving parts, check belt tension, or balance the machine to reduce vibrations.

7. What is the role of chemical detergents in the bottle washing process?

- Remove contaminants: Detergents contain surfactants that help break down and remove dirt, oil, and other contaminants.

- Sanitize: Sanitizing detergents contain antimicrobial agents that kill microorganisms and prevent contamination.

- Prevent scale buildup: Some detergents contain sequestering agents that bind to minerals in water, preventing them from forming scale deposits on the machine’s components.

- Lubricate: Certain detergents contain lubricating agents that help reduce wear and tear on the machine’s moving parts.

8. How do you ensure the quality of washed bottles meets industry standards?

- Visual inspection: Bottles are manually inspected for cleanliness and any visible defects.

- Microbial testing: Samples of washed bottles are periodically tested to ensure compliance with microbiological standards.

- Chemical residue testing: Bottles are tested for residual detergent levels to ensure they meet acceptable limits.

- Documentation: All quality control checks and results are documented to maintain traceability and demonstrate compliance.

9. What are the safety precautions to take when handling chemical detergents for bottle washing?

- Wear appropriate PPE, including gloves, safety glasses, and a mask to prevent contact with chemicals.

- Handle detergents in a well-ventilated area to avoid inhalation.

- Store detergents securely in designated areas to prevent spills or leaks.

- Follow manufacturer’s instructions for mixing and handling detergents to prevent chemical burns or exposure.

- Dispose of used detergents properly according to environmental regulations to avoid contamination.

10. How do you stay up-to-date on the latest advancements in bottle washing technology?

- Attend industry conferences and exhibitions.

- Read technical journals and publications.

- Network with other professionals in the industry.

- Participate in training programs offered by manufacturers or industry organizations.

- Stay informed about new regulations and standards related to bottle washing.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bottle Washing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bottle Washing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bottle Washing Machine Operators are responsible for maintaining the cleanliness of beverage or pharmaceutical containers. They operate automated machinery that cleans and sanitizes bottles and other containers. This ensures that the containers are free of contaminants and safe for use in packaging food and beverages.

1. Maintain and operate bottle washing machines

Operate and monitor bottle washing machines to ensure they are operating correctly. Troubleshoot malfunctions and perform routine maintenance, such as cleaning and lubrication.

- Monitor the machine’s performance

- Make adjustments to the machine’s settings

- Clean and sanitize the machine

- Repair and replace parts as needed

2. Inspect bottles for defects

Inspect bottles for cracks, dents, and other defects. Remove damaged bottles from the line.

- Visually inspect bottles

- Use a lightbox or other tool to detect defects

- Remove damaged bottles from the line

3. Load and unload bottles

Load bottles into the washing machine and unload them when they are clean.

- Load bottles into the machine

- Unload bottles from the machine

- Stack bottles on pallets or conveyors

4. Clean and sanitize work area

Clean and sanitize the work area to prevent contamination.

- Sweep and mop the floor

- Wipe down surfaces

- Dispose of waste

Interview Tips

Preparing for an interview can be stressful, but by following these tips, you can increase your chances of success.

1. Research the company and the position

Before the interview, take some time to learn about the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job.

- Visit the company’s website

- Read the job description

- Talk to people who work at the company

2. Practice your answers to common interview questions

There are common interview questions that are asked in almost every interview. By practicing your answers to these questions, you can feel more confident and prepared during the interview.

- “Tell me about yourself.”

- “Why are you interested in this job?”

- “What are your strengths and weaknesses?”

- “Why should we hire you?”

3. Prepare questions to ask the interviewer

Asking questions at the end of the interview shows that you are interested in the job and the company. It also gives you an opportunity to learn more about the company culture and the position you are applying for.

- “What is the company culture like?”

- “What are the biggest challenges facing the company?”

- “What are the opportunities for advancement?”

- “What is the next step in the hiring process?”

4. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows that you are respectful of the interviewer’s time and that you are serious about the job.

- Wear business attire

- Arrive on time

- Be polite and respectful

- Make eye contact

- Be enthusiastic and positive

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Bottle Washing Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.