Are you gearing up for a career in Bottling Line Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Bottling Line Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

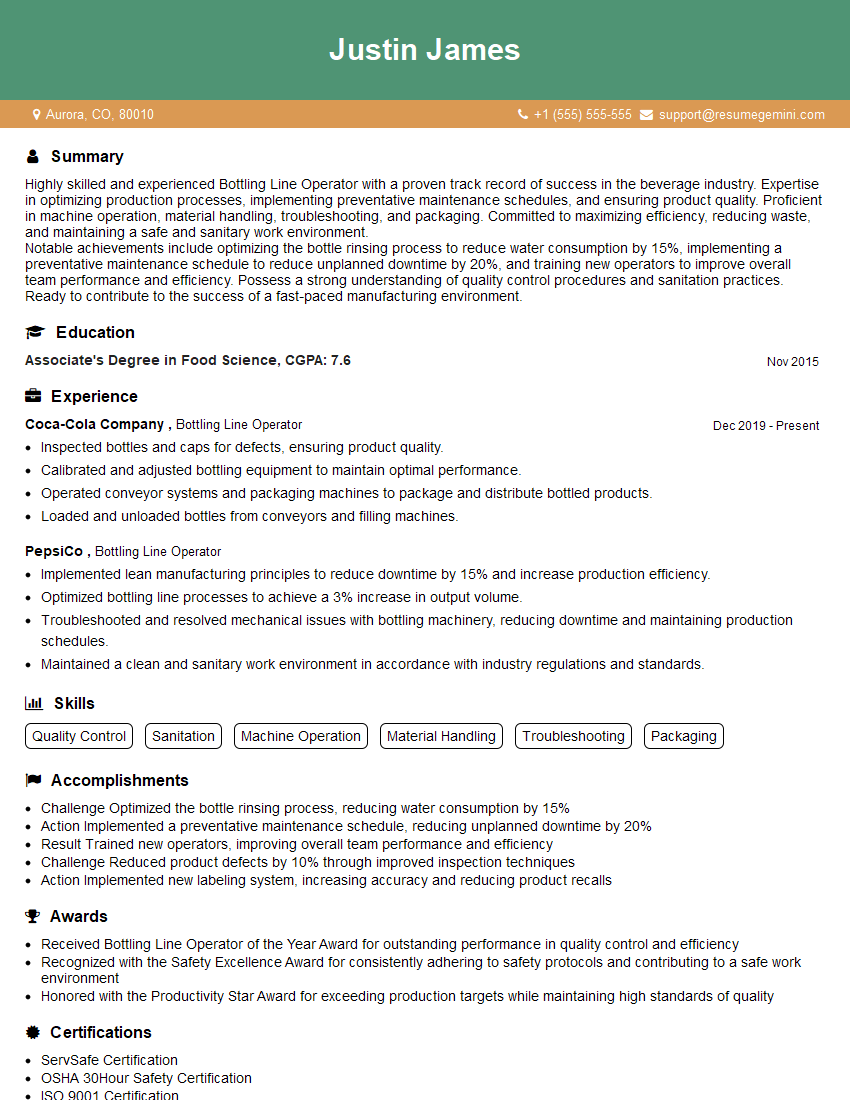

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bottling Line Operator

1. Explain the process of bottle inspection on the bottling line?

The process of bottle inspection on the bottling line involves several key steps to ensure the quality and safety of the bottles used for filling:

- Bottle Cleaning: Bottles are initially cleaned using a caustic solution to remove any dirt, debris, or contaminants.

- Visual Inspection: Bottles are then visually inspected for any defects, cracks, or chips that could compromise their integrity.

- Dimensional Inspection: Bottles are measured to ensure they meet the correct height, diameter, and volume specifications.

- Internal Pressure Testing: Bottles may undergo internal pressure testing to verify their strength and resistance to breakage.

- Sanitization: Bottles are sanitized using a chemical solution to eliminate any remaining microorganisms or bacteria.

2. How do you maintain and calibrate the filling equipment on the bottling line?

Daily Maintenance

- Clean and inspect filling nozzles.

- Check and adjust filling levels.

- Lubricate moving parts.

Weekly Calibration

- Calibrate filling volumes using standard weights.

- Test and adjust filling speeds.

- Verify accuracy of sensors and controls.

3. What are the key safety procedures you follow when operating the bottling line?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and earplugs.

- Follow lockout/tagout procedures when servicing or cleaning equipment.

- Be aware of pinch points and moving machinery.

- Maintain a clean and organized work area.

- Report any hazards or potential safety issues immediately.

4. How do you troubleshoot common bottling line problems, such as leaks or bottle jams?

- Leaks: Identify the source of the leak (e.g., filling nozzle, valve, hose) and tighten or replace the faulty component.

- Bottle Jams: Check for blockages in the conveyor system or filling machine. Remove any stuck bottles and inspect for damage.

- Incorrect Filling Levels: Adjust the filling machine settings or recalibrate the equipment.

- Labeling Issues: Inspect the labeling machine for alignment and proper functioning. Ensure the correct labels are being used.

5. How do you work effectively as part of a team on the bottling line?

- Communicate clearly and effectively with team members.

- Cooperate and assist with various tasks.

- Share knowledge and expertise.

- Support and cover for other team members when needed.

- Maintain a positive and collaborative work environment.

6. What is your experience with quality control procedures on the bottling line?

- Monitored product quality throughout the bottling process.

- Conducted random inspections of bottles for defects or contamination.

- Documented and reported quality control findings.

- Took corrective actions to ensure product standards were met.

7. How do you prioritize tasks and manage your time effectively on a fast-paced bottling line?

- Set priorities based on urgency and importance.

- Create a daily task list and allocate time accordingly.

- Delegate tasks when possible.

- Utilize time-saving techniques and eliminate unnecessary distractions.

- Communicate regularly with team members to adjust priorities as needed.

8. What are some of the challenges you have faced as a Bottling Line Operator and how did you overcome them?

Challenge: Bottle Jams

Solution: Identified the cause of the jams (e.g., equipment malfunction, damaged bottles) and implemented corrective measures.

Challenge: Inaccurate Filling Levels

Solution: Recalibrated the filling equipment, ensuring precise filling volumes.

9. What motivates you to perform your role as a Bottling Line Operator to the best of your ability?

- Ensuring product quality and safety for consumers.

- Contributing to the smooth and efficient operation of the bottling line.

- Working as part of a team and supporting my colleagues.

- Taking pride in my work and meeting production targets.

10. Why are you interested in this Bottling Line Operator position at our company?

- Your company’s reputation for producing high-quality beverages.

- The opportunity to contribute my skills and experience to your bottling line operations.

- The chance to learn from experienced professionals and advance my career.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bottling Line Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bottling Line Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bottling Line Operators play a crucial role in the production of bottled beverages, ensuring efficient and seamless operations. Their key responsibilities include:

1. Machine Operation and Maintenance

Operate and monitor bottling machines, including conveyors, fillers, cappers, and labelers.

- Adjust machine settings to ensure optimal performance.

- Perform routine maintenance and troubleshooting to prevent downtime.

2. Product Quality Control

Inspect bottles and beverages for defects, contamination, and adherence to quality standards.

- Conduct visual and functional inspections.

- Adjust filling parameters to achieve desired product specifications.

3. Production Monitoring and Optimization

Monitor production lines to ensure smooth and efficient operation.

- Identify bottlenecks and implement solutions to improve productivity.

- Maintain production records and report any anomalies or deviations.

4. Sanitation and Safety

Maintain a clean and hygienic work environment.

- Follow established sanitation protocols.

- Adhere to all safety regulations and wear appropriate personal protective equipment.

Interview Tips

Preparing thoroughly for your Bottling Line Operator interview is essential to showcase your skills and impress the hiring manager. Consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s mission, products, and industry standing.

- Visit the company website and read industry news.

- Identify the specific responsibilities of the Bottling Line Operator position.

2. Highlight Relevant Experience and Skills

Emphasize your experience in operating bottling equipment and maintaining a clean and safe work environment.

- Quantify your accomplishments using specific metrics and examples.

- Showcase your ability to identify and resolve problems quickly and efficiently.

3. Demonstrate Technical Proficiency

Be prepared to discuss your understanding of bottling machinery, sanitation practices, and quality control procedures.

- Explain the troubleshooting steps you take when encountering machine malfunctions.

- Describe the quality standards you adhere to and how you ensure compliance.

4. Showcase Your Work Ethic and Commitment

Highlight your reliability, attention to detail, and ability to work as part of a team.

- Share examples of how you maintained a high level of productivity and quality.

- Explain how you prioritize safety and cleanliness in your work environment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bottling Line Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!