Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Bottling Room Worker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

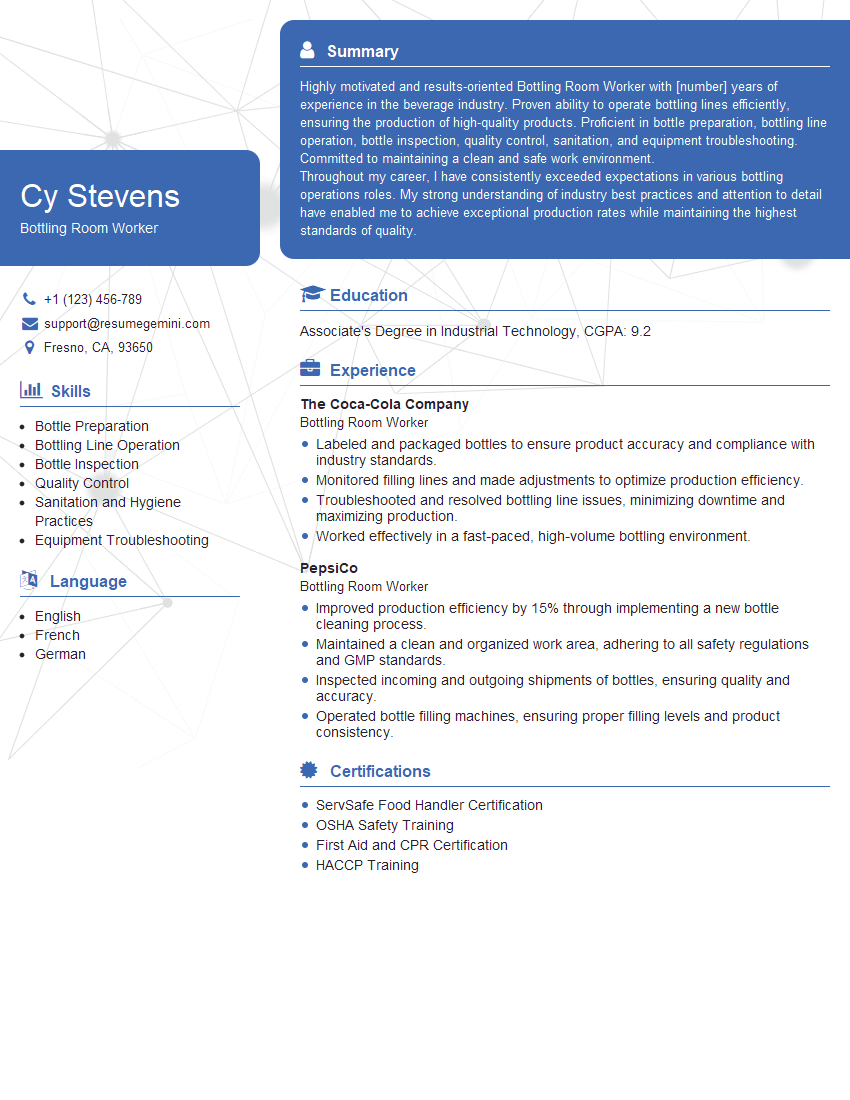

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bottling Room Worker

1. What are the different types of bottles used in the bottling process?

There are various types of bottles used in the bottling process, including:

- Glass bottles: These are the most common type of bottles used for beverages and are made from recycled or new glass.

- Plastic bottles: These are lightweight and shatter-resistant, making them popular for soft drinks, water, and other beverages.

- Aluminum cans: These are lightweight and recyclable, and are commonly used for beer, soda, and energy drinks.

- PET bottles: These are made from polyethylene terephthalate and are lightweight and shatter-resistant, making them suitable for various beverages.

2. Describe the process of filling a bottle on a bottling line.

The process of filling a bottle on a bottling line typically involves the following steps:

- Bottle Cleaning: Bottles are cleaned and inspected before filling to remove any impurities or contaminants.

- Bottle Rinsing: Bottles are rinsed with water or a sanitizing solution to further clean and remove any residual contaminants.

- Filling: The bottle is filled with the desired beverage using a filling valve that controls the volume and pressure.

- Capping: Once filled, the bottle is capped using a capping machine that applies a seal or closure to prevent leakage.

- Labeling: Labels are applied to the bottle providing information such as brand, product details, and ingredients.

3. What are the common causes of bottle breakage in the bottling process?

There are several common causes of bottle breakage in the bottling process, including:

- Impact or collision: Bottles can break if they hit or collide with each other or with other objects during handling or transportation.

- Excessive pressure: Bottles can break if the internal pressure from the beverage exceeds the strength of the bottle.

- Thermal shock: Sudden changes in temperature can cause bottles to break, particularly if they are filled with hot or cold liquids.

- Structural defects: Bottles with structural defects or weaknesses can be more prone to breakage.

4. What are the different types of conveyors used in a bottling plant?

There are various types of conveyors used in a bottling plant, including:

- Chain conveyors: These consist of a series of chains that move in a loop, carrying bottles or other items along the line.

- Belt conveyors: These use a continuous belt that moves bottles or items along a flat surface.

- Roller conveyors: These consist of rotating rollers that support and move bottles or items.

- Screw conveyors: These use a spiral-shaped screw that moves bottles or items along a trough or tube.

- Pneumatic conveyors: These use compressed air to transport bottles or items through tubes or pipes.

5. What are the safety precautions that should be taken when working in a bottling plant?

To ensure safety in a bottling plant, it’s crucial to adhere to the following precautions:

- Wear appropriate safety gear: This includes safety glasses, sturdy shoes, and gloves to protect against potential hazards.

- Be aware of your surroundings: Pay attention to moving machinery, conveyor belts, and potential tripping hazards.

- Follow proper lifting techniques: Use proper posture and techniques when lifting heavy objects to avoid injuries.

- Use equipment safely: Ensure that you are trained and authorized to operate machinery and equipment correctly.

- Report any hazards or accidents: Immediately report any unsafe conditions, spills, or accidents to a supervisor.

6. What are the different types of sensors used in a bottling line?

Various types of sensors are used in a bottling line to monitor and control different aspects of the process, including:

- Fill level sensors: These ensure that bottles are filled to the correct level.

- Pressure sensors: These monitor the pressure inside bottles to prevent overfilling or breakage.

- Temperature sensors: These measure the temperature of the beverage or filling environment.

- Proximity sensors: These detect the presence of bottles or other objects without physical contact.

- Vision sensors: These use cameras to inspect bottles for defects or contamination.

7. What are the maintenance tasks that need to be performed on bottling equipment?

To ensure the smooth operation of bottling equipment, regular maintenance tasks are essential, including:

- Cleaning and lubrication: Equipment should be cleaned and lubricated regularly to prevent buildup and wear.

- Inspection and adjustment: Regularly inspecting and adjusting components helps ensure optimal performance.

- Filter replacement: Filters in the filling and cleaning systems should be replaced as per the manufacturer’s recommendations.

- Calibration: Sensors and other measuring devices should be calibrated to ensure accuracy.

- Planned maintenance: Scheduled maintenance helps identify and address potential issues before they become significant problems.

8. What are the quality control procedures followed in a bottling plant?

To ensure the quality and safety of bottled beverages, various quality control procedures are followed, including:

- Raw material inspection: Incoming raw materials, such as bottles and beverages, are inspected for quality.

- In-process inspection: Bottles are inspected throughout the filling and packaging process to identify any defects or contamination.

- Finished product testing: Random samples of finished products are tested to ensure they meet the required quality standards.

- Microbiological testing: Regular testing is conducted to monitor for the presence of microorganisms or contaminants.

- Documentation and record-keeping: All quality control procedures and results are documented and maintained for traceability and regulatory compliance.

9. What are the environmental considerations in a bottling plant?

Bottling plants have environmental responsibilities to minimize their impact on the surroundings, including:

- Water conservation: Implementing water-saving measures in cleaning and rinsing processes.

- Wastewater treatment: Proper treatment of wastewater generated from the plant to prevent pollution.

- Energy efficiency: Using energy-efficient equipment and practices to reduce energy consumption.

- Recycling and waste management: Establishing recycling programs for materials such as bottles, cardboard, and plastic.

- Sustainable packaging: Exploring the use of recyclable or biodegradable packaging materials.

10. How do you handle working in a fast-paced environment with production targets?

In a fast-paced bottling plant environment, I thrive on the challenge of meeting production targets efficiently and accurately. I maintain a high level of focus and prioritize tasks effectively to ensure timely completion. By staying organized and working collaboratively with my team, we can collectively achieve the desired output without compromising quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bottling Room Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bottling Room Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bottling Room Workers are responsible for a variety of tasks in the bottling process, including:

1. Preparation

Prepare bottling equipment, including rinsing, sanitizing, and inspecting bottles and caps.

- Inspect incoming bottles and caps for defects.

- Rinse and sanitize bottles and caps using automated equipment or hand-washing techniques.

2. Filling

Fill bottles with product according to specifications.

- Operate bottling machines to fill bottles with the correct amount of product.

- Monitor filling levels and make adjustments as needed.

3. Capping

Apply caps to bottles and ensure they are properly sealed.

- Position caps on bottles using automated equipment or hand-held capping tools.

- Inspect capped bottles for leaks or other defects.

4. Labeling

Label bottles with product information and other required data.

- Apply labels to bottles using automated labelers or hand-held applicators.

- Ensure labels are properly aligned and securely attached.

5. Packaging

Pack finished bottles into cases, cartons, or other containers.

- Load cases or cartons with labeled bottles.

- Seal and stack cases or cartons for storage or shipping.

6. Sanitation

Maintain a clean and sanitary work area.

- Clean and sanitize equipment, work surfaces, and floors regularly.

- Follow established sanitation protocols to prevent contamination of products.

7. Safety

Follow established safety protocols to prevent accidents and injuries.

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs.

- Operate equipment safely and follow proper lifting techniques.

Interview Tips

To effectively prepare for an interview as a Bottling Room Worker, consider the following tips:

1. Research the company and position

Gather information about the company’s history, products, and industry standing. Learn about the specific responsibilities of the Bottling Room Worker role and how it aligns with your skills and experience.

- Check the company’s website and social media pages.

- Review online job boards and industry publications.

2. Practice answering common interview questions

Prepare responses to potential interview questions related to your experience, skills, and motivation. Consider using the STAR method to structure your answers: Situation, Task, Action, Result.

- Describe a time you faced a challenge on the job and how you overcame it.

- Explain how your previous experience has prepared you for the responsibilities of a Bottling Room Worker.

3. Prepare questions for the interviewer

Asking thoughtful questions at the end of the interview demonstrates your interest in the position and the company. It also gives you an opportunity to clarify any information or address any concerns.

- What are the most important qualities you’re looking for in a Bottling Room Worker?

- Can you describe the company’s growth plans and how this position fits into those plans?

4. Dress appropriately and arrive on time

First impressions matter, so it’s important to dress professionally and arrive for your interview on time. This shows that you respect the interviewer’s time and are serious about the position.

- Choose business casual attire, such as a button-down shirt, dress pants, or a skirt.

- Arrive at the interview location 10-15 minutes early to allow for any unexpected delays.

5. Be yourself and be confident

Authenticity and confidence are key to a successful interview. Be honest about your skills and experience, and don’t be afraid to show your enthusiasm for the position.

- Speak clearly and confidently, and make eye contact with the interviewer.

- Be enthusiastic and positive throughout the interview.

Next Step:

Now that you’re armed with the knowledge of Bottling Room Worker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Bottling Room Worker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini