Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Bottom Cementer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

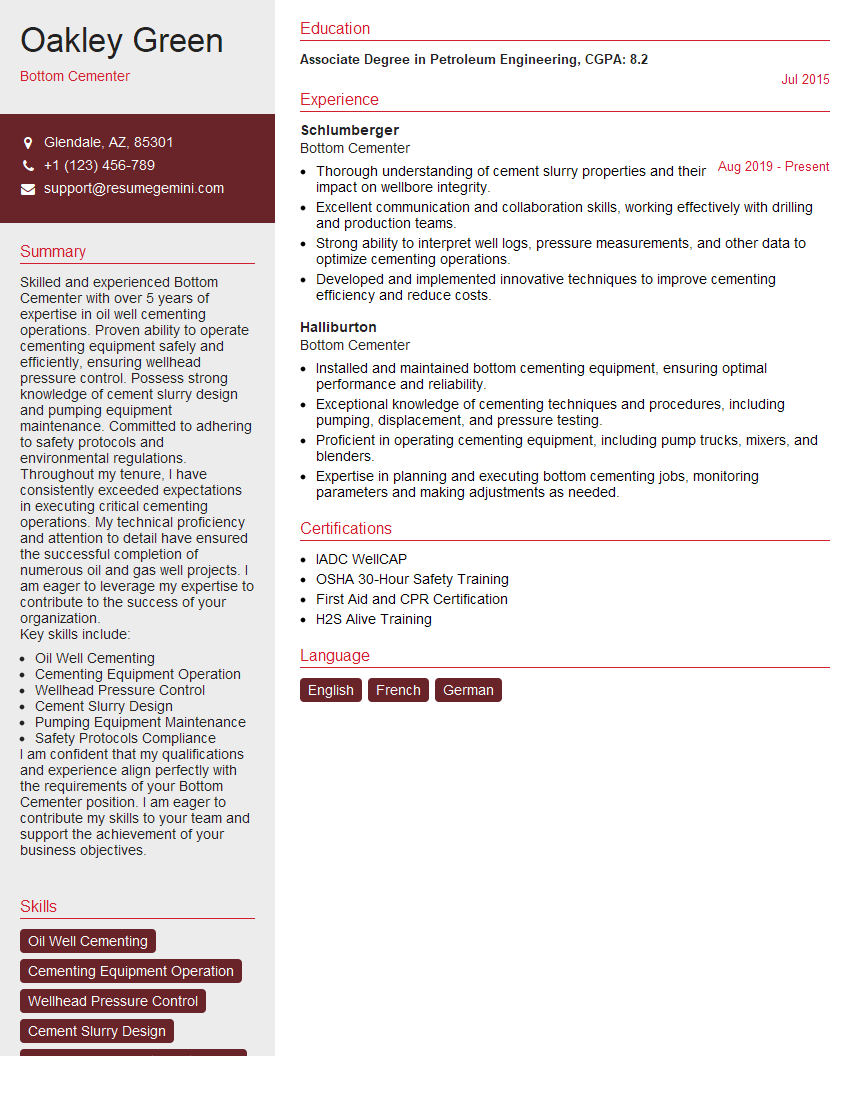

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bottom Cementer

1. Explain the process of cementing a bottom?

The process of cementing a bottom involves the following steps:

- Inspect the bottom to ensure it is clean and free of any debris or damage.

- Apply a thin layer of cement to the bottom using a trowel.

- Spread the cement evenly over the bottom, making sure to fill in any gaps or cracks.

- Smooth the cement using a trowel to create a level surface.

- Allow the cement to dry for the specified amount of time before using the bottom.

2. What are the different types of cement that can be used for bottom cementing?

The different types of cement that can be used for bottom cementing include:

- Portland cement

- Masonry cement

- Hydraulic cement

- Epoxy cement

Portland cement

- Most common type of cement used for bottom cementing

- Strong and durable

- Relatively inexpensive

Masonry cement

- Designed for use with masonry materials such as brick and stone

- More flexible than Portland cement

- Can be used in both interior and exterior applications

Hydraulic cement

- Sets quickly and can be used in wet or underwater applications

- More expensive than Portland cement

- Not as strong as Portland cement

Epoxy cement

- Two-part epoxy that creates a strong and durable bond

- Can be used to repair or patch damaged bottoms

- More expensive than other types of cement

3. How do you prepare a bottom for cementing?

To prepare a bottom for cementing, you need to:

- Clean the bottom to remove any dirt, grease, or other contaminants.

- Roughen the surface of the bottom to improve adhesion.

- Wet the bottom to help the cement bond.

4. What are the safety precautions that should be taken when working with cement?

When working with cement, it is important to take the following safety precautions:

- Wear gloves to protect your hands from skin irritation.

- Wear a dust mask to protect your lungs from inhaling cement dust.

- Wear eye protection to protect your eyes from flying cement particles.

- Avoid contact with skin and eyes.

- If cement gets on your skin, wash it off immediately with soap and water.

- If cement gets in your eyes, flush them with clean water for 15 minutes and seek medical attention.

- Keep cement away from children and pets.

5. What are the most common problems that can occur when cementing a bottom?

The most common problems that can occur when cementing a bottom include:

- The cement not adhering to the bottom

- The cement cracking or chipping

- The cement not drying properly

- The cement causing efflorescence

6. How do you troubleshoot and resolve problems that occur when cementing a bottom?

To troubleshoot and resolve problems that occur when cementing a bottom, you need to:

- Inspect the bottom to identify the problem.

- Take steps to correct the problem, such as cleaning the bottom, roughening the surface, or wetting the bottom.

- Re-apply the cement and allow it to dry completely.

7. What are the different tools and equipment that are used for bottom cementing?

The different tools and equipment that are used for bottom cementing include:

- Trowel

- Float

- Edger

- Sponge

- Bucket

- Safety glasses

- Dust mask

- Gloves

8. What are the different techniques that can be used to create different finishes on a cemented bottom?

The different techniques that can be used to create different finishes on a cemented bottom include:

- Troweling

- Floating

- Edging

- Stamping

- Scoring

9. What are the different factors that can affect the drying time of cement?

The different factors that can affect the drying time of cement include:

- The type of cement

- The amount of water used

- The temperature

- The humidity

- The thickness of the cement

10. What are the different ways to protect a cemented bottom from damage?

The different ways to protect a cemented bottom from damage include:

- Sealing the bottom with a clear sealant

- Applying a protective coating to the bottom

- Covering the bottom with a rubber mat

- Using the bottom only for its intended purpose

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bottom Cementer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bottom Cementer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bottom Cementers play a crucial role as they are responsible for ensuring a proper seal between the casing and the wellbore. Their duties involve prepping the casing, mixing and applying cement, and monitoring the cementing process to achieve optimal results.

1. Casing Preparation

Bottom Cementers begin by carefully preparing the casing to ensure a secure bond with the cement.

- Inspecting the casing for any damage, defects, or imperfections that could compromise the seal.

- Cleaning and roughening the casing surface to enhance adhesion between the casing and cement.

2. Cement Mixing and Pumping

After casing preparation, Bottom Cementers are responsible for mixing and pumping the cement slurry into the wellbore.

- Mixing cement according to specifications, ensuring proper proportions of cement, water, and additives.

- Pumping the cement slurry into the wellbore through the casing, displacing the drilling fluid.

3. Cementing Process Monitoring

Throughout the cementing process, Bottom Cementers monitor various parameters to ensure proper cement placement and setting.

- Tracking cement volume and pressure to monitor slurry placement and detect any potential issues.

- Observing cement returns to the surface to assess the displacement of drilling fluid and cement flow.

4. Curing and Finishing

Once the cement is in place, Bottom Cementers oversee the curing and finishing process.

- Monitoring cement temperature and pressure to ensure proper curing and setting.

- Performing pressure tests to verify the integrity of the cement seal.

- Trimming excess cement to prepare for subsequent drilling or completion operations.

Interview Tips

Preparing thoroughly for an interview is crucial. By following these tips and showcasing your skills and experience, you’ll increase your chances of making a strong impression.

1. Research the Company and Position

Gather information about the company’s culture, values, and specific requirements for the Bottom Cementer position. This knowledge will help you tailor your answers to demonstrate your alignment with the company’s goals.

2. Practice Common Interview Questions

Anticipate common interview questions related to your experience, technical skills, and problem-solving abilities. Prepare concise and engaging answers that highlight your strengths and qualifications.

3. Highlight Your Technical Expertise

Emphasize your understanding of cementing principles, techniques, and equipment. Provide specific examples of your involvement in successful cementing operations.

4. Showcase Safety and Environmental Awareness

The oil and gas industry prioritizes safety and environmental protection. Demonstrate your commitment to these aspects by describing your adherence to safety regulations and environmental best practices.

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your interest and engagement. It’s an opportunity to gain insights into the role, the company’s culture, and potential career growth.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bottom Cementer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!