Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Bottom Precipitator Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

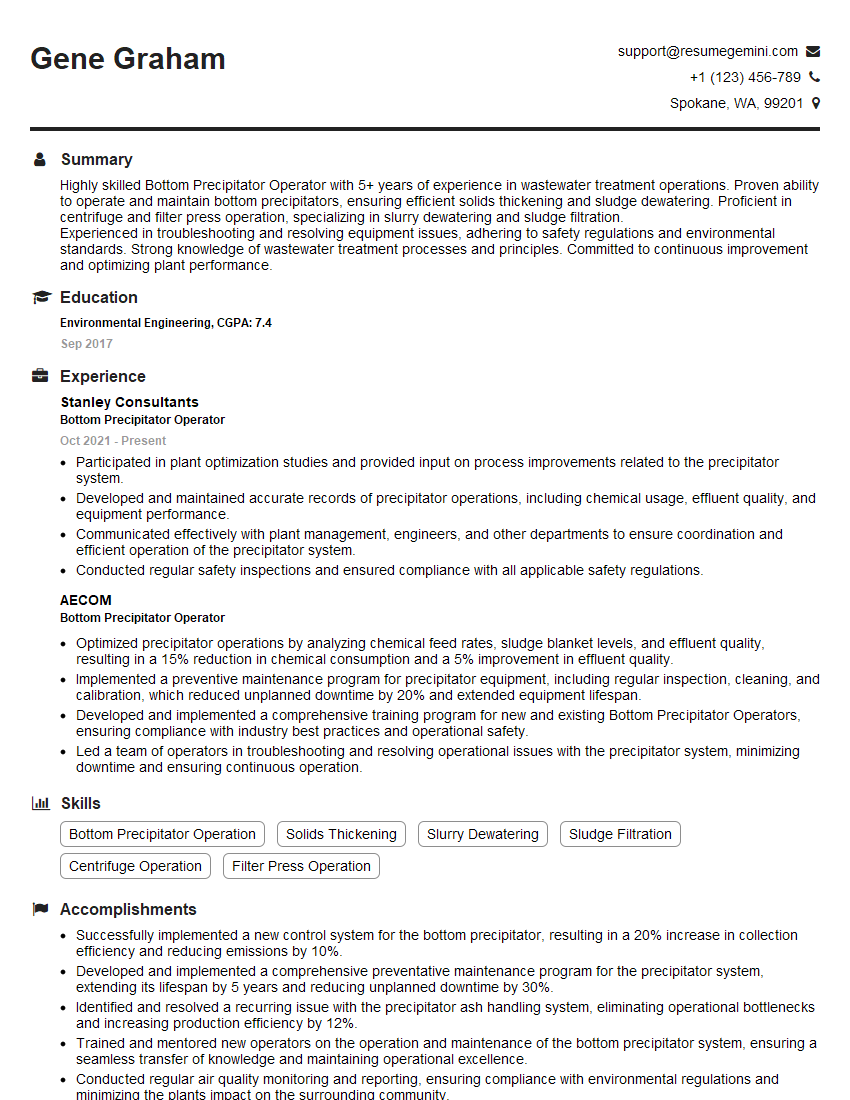

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bottom Precipitator Operator

1. Describe the primary responsibilities of a Bottom Precipitator Operator?

- Monitor and operate the bottom precipitator system to ensure efficient removal of particulate matter from flue gas

- Control and adjust equipment settings to maintain optimal operating conditions, such as temperature, flow rates, and chemical dosages

- Conduct routine inspections and maintenance of the precipitator equipment, including hoppers, electrodes, and rappers

- Troubleshoot and resolve any operational problems with the precipitator system

- Maintain accurate records of operating data and equipment performance

2. Explain the process of bottom ash removal from the precipitator?

- Ash accumulation: Ash particles are collected on the collection surfaces of the precipitator

- Rapping: Collected ash is loosened by rapping or vibrating the collection surfaces

- Hopper filling: Ash falls into the hopper at the bottom of the precipitator

- Ash removal: Ash is periodically removed from the hopper using a screw conveyor or other mechanical system

3. How do you ensure the proper functioning of the discharge electrodes in a bottom precipitator?

- Regular inspections: Visually inspect the electrodes for any damage or deformation

- Electrical testing: Conduct electrical resistance and insulation tests to identify any problems

- Cleaning: Remove any accumulated ash or debris from the electrodes

- Replacement: If necessary, replace damaged or worn electrodes

4. What are the common performance indicators used to evaluate the efficiency of a bottom precipitator, and how do you monitor them?

- Particulate matter removal efficiency: Measured using stack testing or continuous emissions monitoring systems (CEMS)

- Opacity: Measured using opacity monitors to determine the visibility of emissions

- Pressure drop: Measured across the precipitator to monitor air flow resistance

- Current draw: Monitored to ensure proper electrical operation of the electrodes

- Hopper level: Monitored to prevent overfilling and ash carryover

5. Describe the safety precautions necessary when working with a bottom precipitator?

- Electrical hazards: Wear proper protective equipment and follow lockout/tagout procedures when working near high-voltage components

- Confined space entry: Follow proper procedures for entering and exiting enclosed spaces, such as the precipitator hopper

- Falling hazards: Wear appropriate footwear and use fall protection equipment near elevated areas

- Dust exposure: Wear respirators and protective clothing to prevent inhalation of dust and particulates

- Hot surfaces: Be aware of hot surfaces and wear appropriate gloves and clothing to avoid burns

6. Explain how the performance of a bottom precipitator can be affected by changes in operating conditions?

- Gas flow rate: Increased flow can reduce residence time, lowering efficiency

- Temperature: Higher temperatures can increase ash resistivity, affecting collection

- Particulate load: Heavier ash loads can reduce efficiency and require more frequent cleaning

- Electrode voltage: Proper voltage is crucial for effective particle charging and collection

- Chemical additives: Injecting additives like ammonia can enhance particle collection

7. How do you troubleshoot a bottom precipitator that is experiencing reduced efficiency?

- Inspect discharge electrodes: Check for damage, fouling, or misalignment

- Clean collection plates: Remove any accumulated ash or debris to improve surface area

- Verify gas flow: Ensure proper flow rate and distribution within the precipitator

- Check electrical connections: Verify power supply and connections to the electrodes

- Examine hopper: Inspect for leaks, blockages, or overfilling that could affect ash removal

8. How do you optimize the operation of a bottom precipitator to achieve maximum efficiency and reliability?

- Regular maintenance: Perform scheduled inspections and repairs to maintain equipment integrity

- Monitoring and adjustments: Continuously monitor operating parameters and make adjustments to optimize performance

- Training and supervision: Ensure operators are well-trained and supervised to follow proper procedures

- Use of instrumentation: Utilize instruments like opacity monitors and CEMS to track performance and identify issues early

- Collaboration: Work closely with other plant personnel to address factors that may affect precipitator operation

9. Explain the different types of bottom precipitator designs?

- Plate-type: Uses parallel plates as collection surfaces for particles

- Tubular-type: Employs vertical or horizontal tubes as collecting elements

- Baghouse-type: Utilizes fabric filter bags to capture particulate matter

- Dry electrostatic precipitator (ESP): Collects particles using electrostatic forces without using water

- Wet electrostatic precipitator (WESP): Combines electrostatic collection with water scrubbing to enhance particulate removal

10. Describe the environmental regulations and standards that apply to bottom precipitator operation?

- Clean Air Act: Sets limits on particulate matter emissions from industrial sources

- EPA regulations: Specific requirements for precipitator design, operation, and monitoring

- State and local regulations: May have additional or more stringent requirements

- Permit requirements: Facilities must obtain permits that outline emission limits and monitoring protocols

- Compliance monitoring: Regular testing and reporting ensures compliance with regulations

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bottom Precipitator Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bottom Precipitator Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bottom Precipitator Operators are responsible for the safe and efficient operation of bottom precipitators, which remove particulate matter from industrial exhaust gases.

1. Monitor and Control Precipitator Operation

Operators monitor and control the operation of precipitators, including the electrical power supply, gas flow rate, and particulate collection efficiency.

- Adjust precipitator settings to maintain optimal operating conditions.

- Monitor alarms and other indicators to identify and respond to operational issues.

2. Maintain and Repair Precipitator Equipment

Operators perform routine maintenance on precipitators, including cleaning, greasing, and replacing worn parts.

- Clean and inspect precipitator components, such as electrodes, plates, and rappers.

- Repair or replace damaged components to ensure proper operation.

3. Troubleshoot and Resolve Problems

Operators troubleshoot and resolve problems with precipitators, including electrical faults, gas leaks, and particulate buildup.

- Identify the source of problems using diagnostic tools and procedures.

- Repair or replace faulty components to restore precipitator operation.

4. Ensure Compliance with Environmental Regulations

Operators ensure that precipitators comply with environmental regulations for particulate emissions.

- Test and calibrate precipitators to meet regulatory requirements.

- Maintain records and documentation to demonstrate compliance.

Interview Tips

To ace an interview for a Bottom Precipitator Operator position, candidates should prepare by researching the company, the industry, and the specific role.

1. Research the Company and Industry

Learn about the company’s history, products/services, and environmental performance.

- Review the company’s website, annual reports, and sustainability reports.

- Understand the industry’s environmental regulations and challenges.

2. Review Job Description and Key Responsibilities

Thoroughly review the job description and identify the key responsibilities of the Bottom Precipitator Operator role.

- Prepare examples of your experience and skills that align with each responsibility.

- Quantify your accomplishments whenever possible, using specific metrics.

3. Practice Common Interview Questions

Prepare for common interview questions, such as:

- “Tell me about your experience operating and maintaining precipitators.”

- “How do you ensure that precipitators meet environmental regulations?”

- “What are your strengths and weaknesses as a Precipitator Operator?”

4. Highlight Transferable Skills

If you lack direct experience as a Bottom Precipitator Operator, emphasize transferable skills from other roles, such as:

- Industrial equipment operation and maintenance

- Electrical troubleshooting

- Environmental compliance and monitoring

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bottom Precipitator Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!