Are you gearing up for a career in Bottom Saw Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Bottom Saw Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

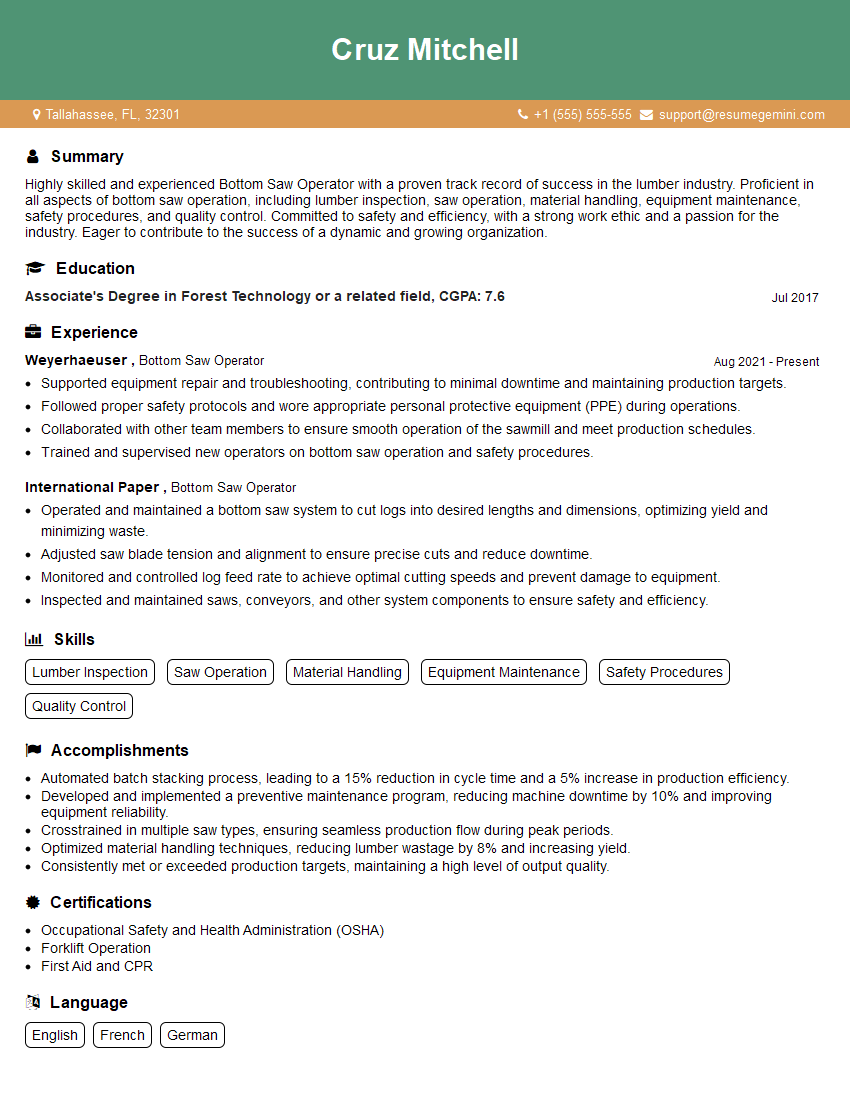

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bottom Saw Operator

1. Describe the key responsibilities of a Bottom Saw Operator.

As a Bottom Saw Operator, I would be primarily responsible for operating and maintaining bottom saws used in the production process. My key responsibilities would include:

- Set up and operate bottom saws to cut logs into specified lengths and dimensions.

- Monitor the sawing process and make adjustments as needed to ensure accurate and efficient cutting.

- Inspect and maintain bottom saws regularly to ensure optimal performance and safety.

- Troubleshoot and resolve any operational issues that may arise with the bottom saws.

- Adhere to safety protocols and maintain a clean and organized work area.

2. Explain the process of setting up a bottom saw for a specific cutting job.

Equipment Preparation

- Ensure the saw is securely mounted and properly aligned.

- Inspect saw blades for sharpness and replace if necessary.

- Set up the feed mechanism and adjust the feed rate.

Material Preparation

- Measure and mark the logs according to the desired cut specifications.

- Position the logs on the feed table and secure them properly.

Machine Settings

- Select the appropriate saw blade speed and feed rate for the material being cut.

- Set the blade depth and angle of cut as per the job requirements.

3. How do you maintain the accuracy and efficiency of a bottom saw?

Maintaining the accuracy and efficiency of a bottom saw requires regular maintenance and calibration:

- Blade Maintenance: Sharpen or replace saw blades regularly to ensure clean and precise cuts.

- Alignment Checks: Verify the alignment of the saw blade, feed table, and fence to ensure accurate cutting.

- Lubrication: Lubricate moving parts and bearings to reduce friction and extend equipment life.

- Feed Rate Adjustment: Optimize feed rate based on the material being cut to achieve desired cut quality and efficiency.

- Regular Inspections: Conduct routine inspections to identify any potential issues or signs of wear and tear.

4. Describe your experience in troubleshooting and resolving bottom saw issues.

During my previous role as a Bottom Saw Operator, I encountered various operational issues and developed a systematic approach to troubleshooting and resolution:

- Blade Problems (e.g., dullness, breakage): Check blade condition and sharpness, adjust tension, and replace if necessary.

- Feed System Malfunctions: Inspect feed rollers, belts, and motors for any damage or misalignment, and make necessary adjustments.

- Alignment Issues: Verify the alignment of saw blade, fence, and feed table using precision measuring tools, and make adjustments as required.

- Material Handling Problems: Ensure logs are properly secured on the feed table, adjust feed rate, and consider using additional support devices if necessary.

- Electrical Faults: Check for loose connections, faulty wiring, or tripped circuit breakers, and consult with an electrician if needed.

5. Explain the safety precautions you follow when operating a bottom saw.

Safety is paramount when operating a bottom saw. I strictly adhere to the following precautions:

- Personal Protective Equipment: Wear appropriate safety gear including gloves, eye protection, earplugs, and a dust mask.

- Machine Guarding: Ensure all guards and shields are in place and functional to prevent contact with moving parts.

- Material Handling: Handle logs carefully, use proper lifting techniques, and secure them firmly on the feed table.

- Blade Maintenance: Inspect blades regularly for damage and sharpness, replace or sharpen as needed, and never operate with a damaged blade.

- Electrical Safety: Check electrical connections regularly, avoid contact with exposed wires, and report any electrical issues promptly.

6. Describe your experience in using different types of bottom saws.

I have worked with various types of bottom saws in my previous roles, including:

- Horizontal Bottom Saws: Used for cutting logs into specific lengths, primarily in sawmills and lumber production facilities.

- Vertical Bottom Saws: Suitable for more precise cuts, often found in furniture manufacturing and woodworking shops.

- CNC-Controlled Bottom Saws: Computer-controlled machines that offer automated cutting and increased precision.

7. How do you handle situations where the bottom saw is not performing optimally?

When the bottom saw is not performing optimally, I take the following steps:

- Inspect the Machine: Check for any visible issues with the saw, such as loose belts, damaged blades, or misalignment.

- Troubleshoot the Problem: Identify the potential cause of the issue by considering factors like blade condition, feed rate, and material characteristics.

- Resolve the Issue: Implement corrective actions such as blade replacement, adjustment of feed rate, or recalibration of the machine.

- Monitor Performance: After resolving the issue, I monitor the saw’s performance to ensure it is operating correctly and producing the desired results.

8. What are the key performance indicators (KPIs) you use to measure your effectiveness as a Bottom Saw Operator?

- Production Output: Number of logs cut per hour or shift.

- Cut Accuracy: Percentage of logs cut within specified dimensions.

- Machine Uptime: Percentage of time the bottom saw is operational and available for use.

- Material Waste: Amount of material lost due to inaccurate cuts or improper handling.

- Safety Compliance: Adherence to safety protocols and absence of accidents or incidents.

9. How do you stay up-to-date with the latest industry advancements in bottom saw technology?

To stay abreast of industry advancements in bottom saw technology, I engage in the following activities:

- Attend Trade Shows and Exhibitions: Visit industry events to learn about new equipment and technologies.

- Read Industry Publications: Subscribe to magazines and journals that cover advancements in sawmilling and woodworking.

- Attend Training Programs: Participate in workshops and seminars offered by equipment manufacturers or industry organizations.

- Network with Peers: Connect with other Bottom Saw Operators and industry professionals to exchange knowledge and experiences.

10. How do you handle situations where you need to prioritize multiple tasks while operating a bottom saw?

To effectively prioritize multiple tasks while operating a bottom saw, I employ the following strategies:

- Task Prioritization: Assess the importance and urgency of each task and determine their order of execution.

- Time Management: Allocate specific time slots for different tasks to ensure timely completion.

- Delegation: If possible, delegate certain tasks to other team members to free up my time for more critical operations.

- Effective Communication: Communicate my priorities to colleagues and supervisors to minimize interruptions and ensure a smooth workflow.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bottom Saw Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bottom Saw Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bottom Saw Operators are responsible for the safe and efficient operation of bottom saws used in a variety of industries, including lumber, construction, and manufacturing. Below are some of their key responsibilities:

1. Machine Operations

Bottom Saw Operators are responsible for setting up, operating, and maintaining bottom saws. This includes ensuring the saw is properly adjusted, lubricated, and equipped with sharp blades. They must also be able to identify and troubleshoot any problems that may arise during operation.

- Monitor saw blades for wear and tear.

- Change saw blades when necessary.

- Lubricate and maintain saw equipment.

2. Material Handling

Bottom Saw Operators are responsible for handling materials both before and after they are cut. They must be able to load and unload materials onto the saw table, and they must also be able to remove cut pieces from the table safely.

- Position materials on the saw table.

- Secure materials on the saw table.

- Remove cut pieces from the saw table.

- Inspect materials for defects.

3. Quality Control

Bottom Saw Operators are responsible for ensuring that the materials they cut meet quality standards. They must be able to identify and correct any defects that may occur during the cutting process.

- Inspect cut pieces for accuracy.

- Measure cut pieces to ensure they meet specifications.

- Reject or rework cut pieces that do not meet specifications.

4. Safety

Bottom saws are powerful machines, and Bottom Saw Operators must be able to operate them safely at all times. They must be familiar with all safety procedures and must be able to follow them consistently.

- Wear appropriate safety gear.

- Follow all safety procedures.

- Report any safety hazards.

Interview Tips

Preparing for an interview for a Bottom Saw Operator position can be daunting, but with the right preparation, you can increase your chances of success. Here are some tips to help you prepare:

1. Research the Company and the Position

Before you go to your interview, take the time to research the company and the specific position you are applying for. This will help you to understand the company’s culture, values, and goals, and it will also help you to tailor your answers to the specific requirements of the position.

- Visit the company’s website.

- Read articles about the company in trade publications.

- Talk to people who work at the company.

- Review the job description carefully.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- Use the STAR method to answer interview questions.

- Prepare specific examples of your skills and experience.

- Practice your answers with a friend or family member.

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time, or even a few minutes early. This shows that you are respectful of the interviewer’s time and that you are serious about the position.

- Wear clean, pressed clothes.

- Choose clothes that are appropriate for the company culture.

- Arrive at the interview location at least 10 minutes early.

4. Be Enthusiastic and Positive

Interviewers are looking for candidates who are enthusiastic about the position and who are positive about their abilities. Be sure to show your enthusiasm and positivity throughout the interview. This will make you more likeable and it will also increase your chances of success.

- Smile and make eye contact with the interviewer.

- Speak clearly and confidently.

- Be passionate about the position and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bottom Saw Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.