Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Bow Making Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Bow Making Machine Operator so you can tailor your answers to impress potential employers.

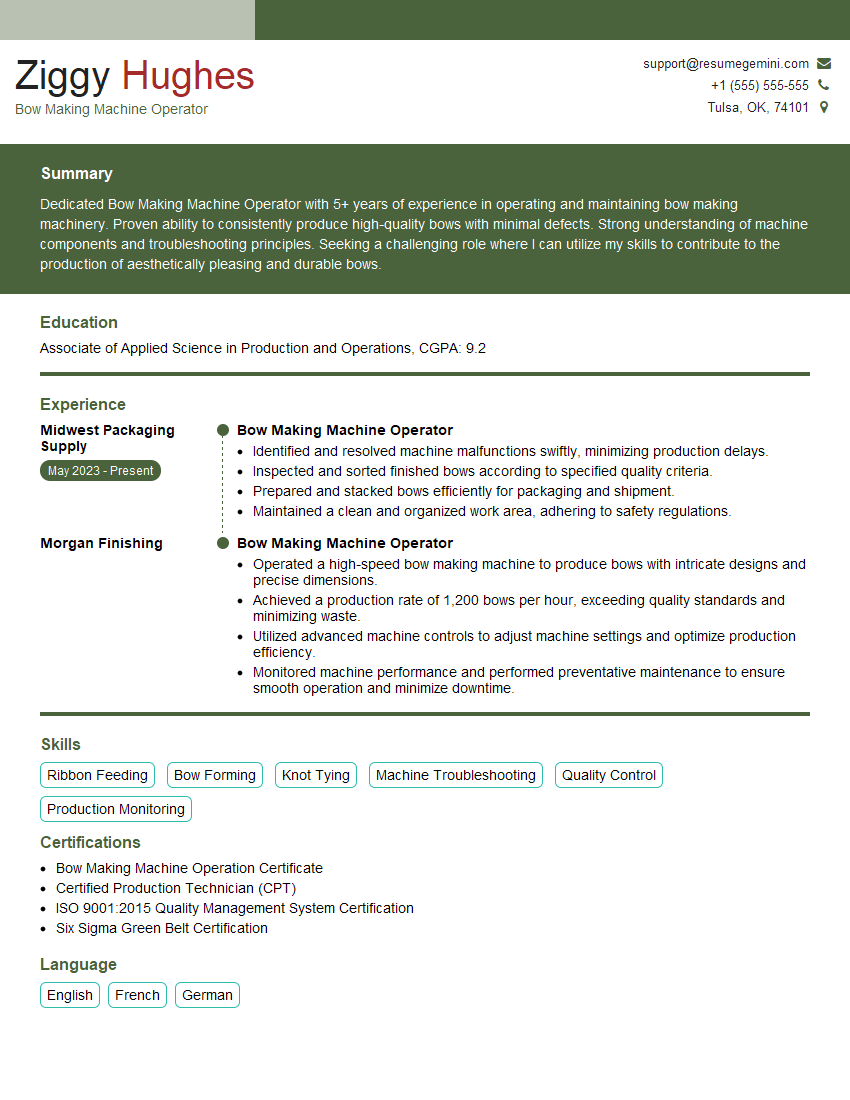

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bow Making Machine Operator

1. Explain the process of setting up and operating a bow making machine?

- Secure the machine to a stable surface and connect it to an appropriate power source.

- Load the machine with the necessary materials (wood blanks, glue, etc.).

- Adjust the machine settings according to the desired bow specifications.

- Start the machine and monitor its operation, making adjustments as needed.

2. What are the different types of bows made using the machine and their applications?

- Recurve bows: Known for their power and speed, these bows are popularly used for target shooting, hunting, and other recreational activities.

- Longbows: Traditional bows with a simple design, longbows are often used for target shooting and historical reenactments.

- Compound bows: Advanced bows with a system of pulleys and cams, compound bows offer increased power and accuracy compared to traditional bows.

- Crossbows: Bows mounted on a stock, crossbows are designed for hunting and self-defense, as they can be cocked and held without continuous effort.

3. How do you ensure the accuracy and precision of the bows produced using the machine?

- Properly maintain and calibrate the machine to minimize errors.

- Use high-quality materials and follow precise manufacturing processes.

- Conduct regular inspections and quality control checks to identify and correct any deviations.

- Monitor machine performance data to identify trends and make adjustments as necessary.

4. Describe the safety precautions that need to be observed while operating a bow making machine?

- Wear appropriate safety gear, including eye protection, gloves, and a dust mask.

- Keep the work area clean and organized to prevent accidents.

- Do not operate the machine if it shows any signs of damage or malfunction.

- Follow all manufacturer’s guidelines and safety instructions.

5. What troubleshooting techniques do you use when the bow making machine encounters problems?

- Identify the source of the problem by observing the machine’s behavior and error messages.

- Consult the machine’s manual and documentation for troubleshooting guidance.

- Check for any loose connections, blockages, or damaged components.

- Perform necessary repairs or adjustments to restore the machine’s functionality.

6. How do you maintain and clean the bow making machine to ensure its longevity?

- Regularly clean the machine using appropriate cleaning agents and solvents.

- Lubricate moving parts to reduce friction and wear.

- Inspect and replace worn or damaged components promptly.

- Follow the manufacturer’s recommended maintenance schedule.

7. How do you keep up with the latest advancements in bow making technology?

- Attend industry trade shows and conferences.

- Read technical articles and publications.

- Network with other professionals in the field.

- Take advantage of training and certification programs offered by manufacturers.

8. What is your experience with using different types of wood for bow making?

- Hardwoods: Dense and durable, hardwoods like oak, maple, and hickory are ideal for bows that require strength and durability.

- Softwoods: Lighter and more flexible, softwoods like pine and cedar are suitable for bows that prioritize speed and maneuverability.

- Exotic woods: Offer unique aesthetic qualities and properties, exotic woods like bubinga, purpleheart, and cocobolo enhance the appearance and performance of bows.

9. How do you handle customer inquiries and requests related to bow making?

- Listen attentively to customer needs and requirements.

- Provide expert advice and recommendations based on their preferences and objectives.

- Communicate clearly and effectively, explaining the process and options available.

- Follow up promptly and address any additional questions or concerns.

10. What are your future career goals in the field of bow making?

In the future, I aspire to become a master bow maker, renowned for creating bows of exceptional quality and craftsmanship. I aim to specialize in crafting custom bows tailored to the unique needs of archers, whether they are professional competitors, avid hunters, or recreational enthusiasts. Additionally, I am interested in exploring the potential of new materials and technologies to push the boundaries of bow design and performance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bow Making Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bow Making Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bow Making Machine Operators are responsible for operating and maintaining bow making machines to produce bows for various applications such as musical instruments, hair accessories, and decorative items.

1. Machine Operation

Initiate, monitor, and adjust machine settings and parameters to ensure optimal bow making process.

- Calculate and input material dimensions and specifications into machine controls.

- Perform regular calibration and maintenance to ensure machine accuracy and efficiency.

2. Material Handling

Load, unload, and inspect raw materials and finished bows to ensure adherence to quality standards.

- Identify and sort materials based on type, size, and specifications.

- Conduct visual and tactile inspections to ensure bows meet required dimensions, shape, and finish.

3. Quality Control

Inspect and assess bows to verify adherence to specified quality criteria.

- Utilize measuring tools and gauges to ensure bows meet dimensional specifications.

- Identify and address any deviations or defects in the bow making process.

4. Machine Maintenance

Perform routine and preventative maintenance on bow making machines to ensure optimal performance.

- Lubricate, clean, and inspect machine components to prevent breakdowns.

- Identify and troubleshoot any mechanical or electrical issues that may arise.

Interview Tips

To ace an interview for a Bow Making Machine Operator position, it’s crucial to showcase your technical proficiency, attention to detail, and commitment to quality.

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry trends. This demonstrates interest and enthusiasm for the role.

2. Quantify your Experience

When describing your previous experience, use specific numbers and metrics to quantify your achievements. This helps the interviewer assess your impact on the organization.

3. Highlight your Technical Skills

Emphasize your expertise in operating and maintaining bow making machines, including your knowledge of machine controls, calibration, and troubleshooting.

4. Demonstrate Quality Orientation

Showcase your commitment to quality by highlighting your attention to detail, ability to identify defects, and experience in implementing quality control measures.

5. Prepare for Common Questions

Anticipate and prepare for common interview questions, such as: “Tell me about your experience with bow making machines,” or “How do you ensure the quality of your work?”

6. Ask Thoughtful Questions

Engage with the interviewer by asking thoughtful questions about the company’s bow making process, industry advancements, or opportunities for professional development.

7. Professional Appearance and Attitude

Dress professionally and arrive on time for the interview. Maintain a positive attitude and enthusiasm throughout the conversation to create a favorable impression.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bow Making Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.