Are you gearing up for an interview for a Box Annealer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Box Annealer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

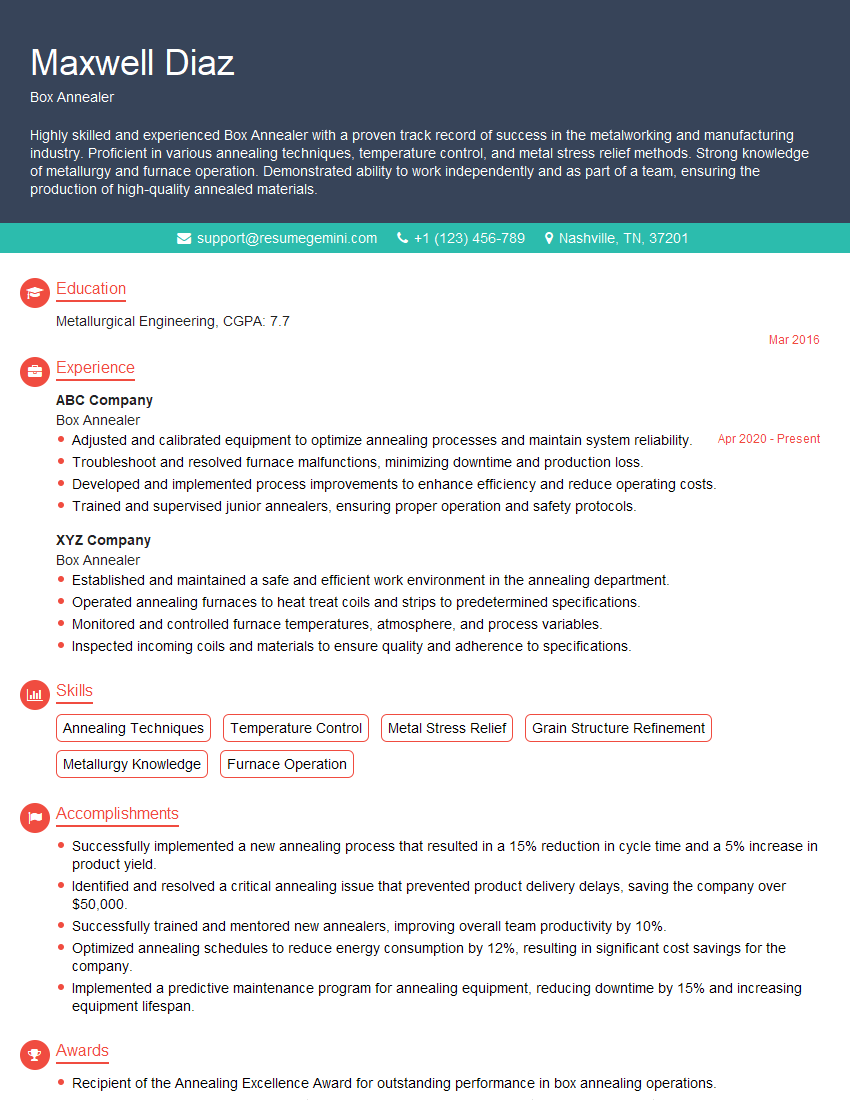

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Box Annealer

1. What methods are employed to test the hardness of the annealed material?

To test the hardness of annealed materials, various methods are commonly employed:

- Rockwell Hardness Test: This widely used non-destructive method measures the depth of indentation created by a diamond or hardened steel ball under a specific load. The resulting hardness value is expressed in Rockwell Hardness (HR) numbers.

- Vickers Hardness Test: Another non-destructive method, the Vickers test utilizes a diamond indenter with a square pyramidal shape. The resulting indentation’s diagonal length is measured and converted into Vickers Hardness (HV) numbers, providing a precise and accurate measure of surface hardness.

- Brinell Hardness Test: Utilizing a hardened steel ball indenter, the Brinell test measures the diameter of the indentation created under a specified load. The resulting hardness value is expressed in Brinell Hardness (HB) numbers, typically suitable for testing softer materials.

2. What factors influence the choice of annealing temperature for a given material?

Desired Material Properties:

- The target hardness, strength, and ductility of the annealed material.

- The specific material’s composition and microstructure.

Process Parameters:

- Annealing time and duration.

- Heating and cooling rates.

- Atmosphere composition.

Equipment Capabilities:

- The maximum temperature and temperature uniformity of the annealing furnace.

3. Explain the process of continuous annealing.

Continuous annealing involves passing a continuously moving metal strip or wire through a series of controlled heating and cooling zones within an annealing furnace:

- Heating Zone: The metal is heated to the desired annealing temperature, allowing for the recrystallization and softening of the material.

- Soaking Zone: The metal is held at the annealing temperature for a specific duration to ensure uniform heating and complete recrystallization.

- Cooling Zone: The metal is cooled at a controlled rate to prevent the formation of a hard and brittle microstructure.

Continuous annealing offers advantages such as high production rates, consistent material properties, and reduced energy consumption.

4. Discuss the role of grain size in the properties of annealed materials.

Grain size significantly impacts the properties of annealed materials:

- Strength: Finer grain sizes generally result in higher strength due to increased grain boundary area, which hinders dislocation movement.

- Ductility: Finer grain sizes typically enhance ductility as grain boundaries provide more paths for dislocation movement, allowing for greater plastic deformation.

- Toughness: Smaller grain sizes can improve toughness by increasing the material’s resistance to crack propagation.

5. How can the surface quality of annealed materials be improved?

- Mechanical Finishing: Techniques like grinding, polishing, or shot peening can remove surface imperfections and improve surface smoothness.

- Chemical Treatments: Pickling or etching can remove surface oxides and contaminants, resulting in a cleaner and more uniform surface.

- Controlled Atmosphere Annealing: Annealing in a protective atmosphere can prevent surface oxidation and discoloration.

- Bright Annealing: This process involves annealing in a reducing atmosphere, such as hydrogen, to create a bright and shiny surface.

6. What are the typical applications of box annealing?

- Annealing of steel sheets for automotive components, appliances, and construction materials.

- Annealing of copper and aluminum alloys for electrical conductors, heat exchangers, and aerospace applications.

- Annealing of stainless steel for cookware, surgical instruments, and chemical processing equipment.

7. Explain the purpose of using a protective atmosphere during box annealing.

A protective atmosphere, such as nitrogen or hydrogen, is used during box annealing to:

- Prevent Oxidation: The atmosphere minimizes the contact of the annealed material with oxygen, reducing surface oxidation and discoloration.

- Control Decarburization: In the case of steel annealing, a protective atmosphere helps maintain the carbon content of the material by preventing decarburization (loss of carbon from the surface).

- Improve Surface Quality: By reducing oxidation and decarburization, the protective atmosphere contributes to a cleaner and brighter surface finish.

8. Describe the steps involved in the box annealing process.

- Loading: The material to be annealed is placed in a protective box or container.

- Purging: The box is purged with a protective gas to remove air and moisture.

- Heating: The box is heated to the desired annealing temperature in a controlled atmosphere furnace.

- Soaking: The material is held at the annealing temperature for a specific duration to achieve uniform heating and complete recrystallization.

- Cooling: The box is cooled at a controlled rate to prevent the formation of a hard and brittle microstructure.

- Unloading: Once cooled, the material is removed from the box.

9. What are the benefits of using a box annealing furnace over other annealing methods?

- Protective Atmosphere: Box annealing allows for the use of a protective atmosphere, which minimizes oxidation and decarburization.

- Uniform Heating: The enclosed nature of the box ensures uniform heating of the material, resulting in consistent properties.

- Batch Processing: Box annealing is suitable for batch processing, making it ideal for smaller production runs or specialized applications.

10. Explain the importance of proper furnace maintenance for box annealing.

- Temperature Control: Regular calibration and maintenance of the furnace ensure accurate temperature control, which is crucial for achieving the desired annealing results.

- Atmosphere Purity: Maintaining the integrity of the protective atmosphere prevents contamination and ensures the material’s surface quality.

- Equipment Reliability: Proper maintenance minimizes downtime and ensures the smooth operation of the furnace, maximizing productivity.

- Safety: Regular inspections and maintenance help identify potential hazards and ensure a safe working environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Box Annealer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Box Annealer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Box Annealer is responsible for operating and maintaining annealing furnaces used in the heat treatment of metals, primarily in the steel industry. Their key job responsibilities include:

1. Furnace Operation

Operate annealing furnaces to heat and cool metal products according to specified temperature and time cycles.

- Monitor furnace temperatures, gas flows, and other process parameters to ensure proper annealing conditions.

- Load and unload metal products into and out of the furnace using appropriate handling equipment.

2. Quality Control

Conduct routine inspections and tests on annealed products to ensure they meet quality standards.

- Measure and verify product dimensions, hardness, and other properties.

- Identify and document any defects or non-conformances in the annealing process.

3. Maintenance and Troubleshooting

Maintain and troubleshoot annealing furnaces and related equipment to ensure optimal performance.

- Inspect and replace furnace components such as heating elements, thermocouples, and gas lines.

- Resolve equipment malfunctions and make necessary repairs to minimize downtime.

4. Safety and Compliance

Adhere to safety regulations and guidelines when operating annealing furnaces and handling metal products.

- Wear appropriate personal protective equipment (PPE) and follow established safety procedures.

- Maintain a clean and organized work area, ensuring compliance with environmental and health regulations.

Interview Tips

To ace an interview for a Box Annealer position, it’s crucial to prepare thoroughly and showcase your relevant skills and experience. Here are some interview prep tips to help you succeed:

1. Research the Company and Position

Gather information about the company, its industry, and the specific Box Annealer role. This will help you understand their business needs and tailor your answers accordingly.

- Visit the company website and LinkedIn page.

- Read industry news and articles related to annealing processes.

2. Highlight Relevant Experience and Skills

Emphasize your hands-on experience operating annealing furnaces, conducting quality control inspections, and troubleshooting equipment. Quantify your accomplishments with specific examples.

- Describe your role in maintaining the annealing process, specifying the types of furnaces you worked with.

- Provide examples of how you identified and resolved technical issues, resulting in improved furnace performance.

3. Demonstrate Safety Awareness and Attention to Detail

Stress your commitment to safety and your ability to work meticulously in a demanding environment.

- Explain your familiarity with industry safety regulations and your compliance with PPE protocols.

- Emphasize your ability to pay close attention to process parameters and detect even minor deviations.

4. Prepare for Technical Questions

Expect technical questions related to annealing processes, metallurgy, and furnace operation. Review basic concepts and be prepared to discuss your knowledge and experience in these areas.

- Describe the different stages of an annealing cycle and the effects on metal properties.

- Explain the principles of temperature control and heat distribution in annealing furnaces.

5. Practice Your Answers

Rehearse your answers to common interview questions and prepare questions to ask the interviewer. This will boost your confidence and allow you to articulate your thoughts clearly.

- Practice answering questions about your experience, skills, and why you’re interested in the role.

- Ask questions that demonstrate your interest in the company’s operations and commitment to safety.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Box Annealer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!