Feeling lost in a sea of interview questions? Landed that dream interview for Box Fabricator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Box Fabricator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

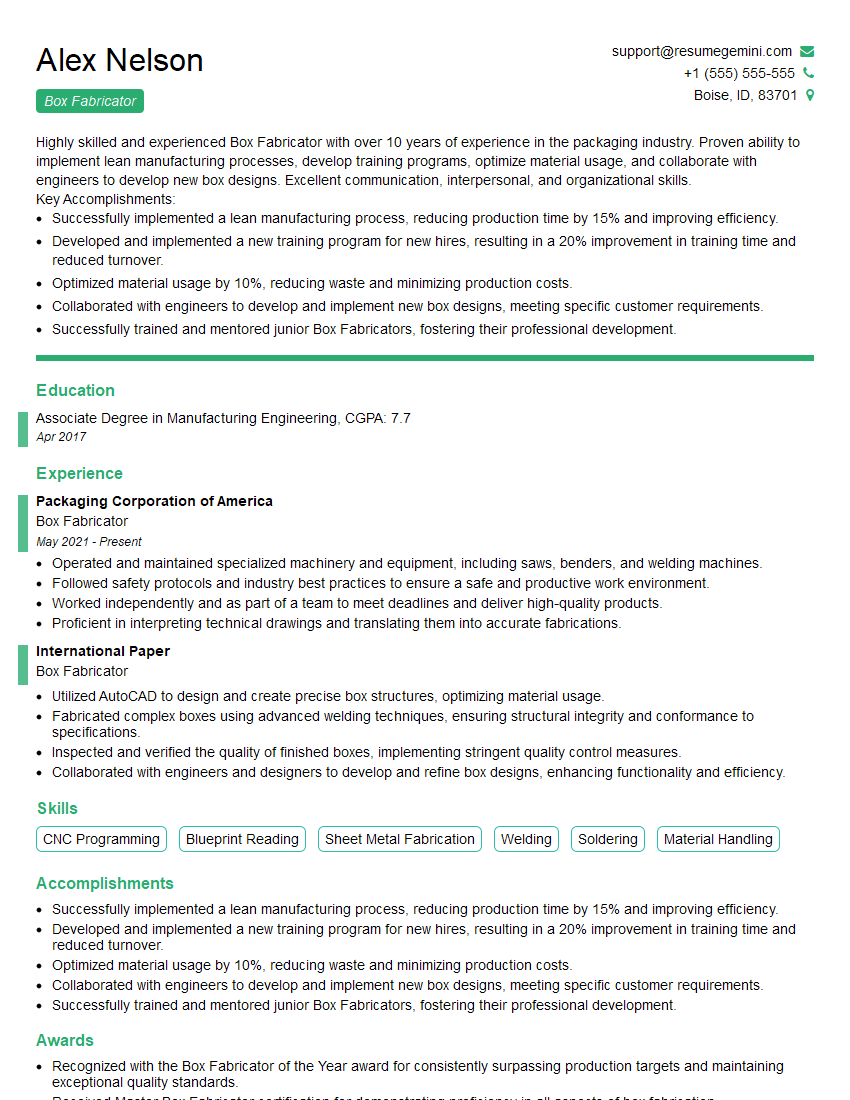

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Box Fabricator

1. Describe the process of bending metal sheets?

Metal bending involves shaping metal sheets into various forms using specialized machinery. The process typically involves the following steps:

- Sheet preparation: The metal sheet is first cleaned and prepared to ensure a smooth bending process.

- Bending: The sheet is placed on a bending machine and subjected to force to achieve the desired shape.

- Measuring and adjustment: The bent sheet is measured and adjusted to meet precise specifications.

- Finishing: The finished product undergoes finishing processes such as deburring, surface treatment, or painting.

2. Explain the different types of welding processes used in box fabrication and their applications.

MIG welding

- Metal Inert Gas (MIG) welding is a semi-automatic process that uses a continuously fed wire electrode shielded by an inert gas.

- Applications: Used for welding thin to medium-thickness metals, such as those used in box fabrication.

TIG welding

- Tungsten Inert Gas (TIG) welding is a manual process that uses a non-consumable tungsten electrode shielded by an inert gas.

- Applications: Precision welding of thin metals, such as those used in electronic enclosures.

Arc welding

- Arc welding uses an electric arc to melt and fuse metals together.

- Applications: Heavy-duty welding applications, such as welding thick metal plates.

3. What are the key factors to consider when designing a box for structural integrity?

Several factors must be considered to ensure the structural integrity of a box:

- Material selection: The type of material used, such as steel, aluminum, or plastic, impacts the box’s strength.

- Box dimensions: The size and shape of the box influence its ability to withstand external forces.

- Joint design: The type of joints used, such as welded, riveted, or bolted, affects the box’s resistance to bending and deformation.

- Load requirements: The box must be designed to withstand the anticipated static and dynamic loads.

4. How do you ensure the quality of your box fabrication process?

Ensuring quality in box fabrication involves implementing various measures:

- Raw material inspection: Inspecting incoming materials for defects or inconsistencies.

- Process control: Establishing and adhering to standardized production processes and guidelines.

- Quality checks: Regularly monitoring and testing products at different stages of production.

- Documentation: Maintaining detailed records of all quality-related activities and inspections.

5. Describe the importance of surface treatment in box fabrication and the different methods used.

Surface treatment is crucial in box fabrication for several reasons:

- Corrosion resistance: Coatings protect the metal from corrosion caused by environmental factors.

- Enhanced durability: Surface treatments increase the box’s overall durability and longevity.

- Improved appearance: Coatings can enhance the box’s aesthetic appeal.

Common surface treatment methods:

- Powder coating

- Electroplating

- Anodizing

6. Explain the role of jigs and fixtures in box fabrication.

Jigs and fixtures are essential tools in box fabrication as they:

- Precision: Ensure accuracy and consistency in component placement and assembly.

- Efficiency: Reduce production time by eliminating manual alignment and measurement.

- Repeatability: Allow for the production of identical boxes repeatedly.

7. What are the different types of materials used in box fabrication and their advantages and disadvantages?

Steel

- Advantages: Strong, durable, readily available, cost-effective.

- Disadvantages: Susceptible to corrosion, heavy.

Aluminum

- Advantages: Lightweight, corrosion-resistant, durable.

- Disadvantages: More expensive than steel, softer.

Plastic

- Advantages: Lightweight, corrosion-resistant, customizable.

- Disadvantages: Lower strength than metal, susceptible to heat deformation.

8. How do you stay up-to-date with the latest advancements in box fabrication technology?

To stay abreast of technological advancements, I engage in the following practices:

- Industry events: Attend trade shows and conferences to learn about new products and techniques.

- Online research: Regularly explore industry publications and online resources.

- Networking: Connect with professionals in the field to exchange knowledge and insights.

- Continuing education: Participate in workshops, seminars, or courses to enhance my skills.

9. Describe a challenging project you faced in box fabrication and how you overcame it.

In a previous project, I encountered a challenge while fabricating a complex box with intricate bends and angles. To overcome this:

- Design optimization: Collaborated with engineers to refine the design and identify potential issues.

- Custom tooling: Developed specialized tooling to achieve the precise bends required.

- Testing and iteration: Conducted multiple tests to validate the design and make necessary adjustments.

10. Why are you interested in this box fabrication position and how do your skills align with the job requirements?

I am eager to join this box fabrication position because it aligns well with my expertise and career aspirations. My skills and experience in:

- Metal fabrication: Proficient in various metalworking techniques, including bending, welding, and assembly.

- Quality control: Committed to maintaining high standards and ensuring the quality of products.

- Problem-solving: Adept at identifying and resolving challenges in the production process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Box Fabricator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Box Fabricator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Box Fabricator is responsible for creating and assembling boxes of various types and sizes, ensuring that they meet the required specifications and quality standards.

1. Production and Assembly

Interpet blueprints, drawings, and work orders to determine the specifications of the boxes to be fabricated.

- Select and cut appropriate materials, such as cardboard, corrugated fiberboard, or other materials, to the specified dimensions.

- Assemble and join the materials using adhesives, tapes, or other methods to create the desired boxes.

- Inspect and ensure the quality of the finished boxes, verifying their dimensions, shape, and strength.

2. Material Handling and Storage

Unload and receive raw materials, such as cardboard, paper, and adhesives, and store them appropriately.

- Maintain inventory of materials, ensuring sufficient supplies to meet production demands.

- Move and handle heavy materials and equipment safely, using proper techniques and equipment.

3. Machine Operation and Maintenance

Operate and maintain machines and equipment used in the fabrication process, such as cutters, presses, and conveyors.

- Monitor machines for proper functioning, identify and resolve any issues, and perform basic maintenance tasks.

- Clean and lubricate machinery regularly to ensure optimal performance and prevent breakdowns.

4. Safety and Compliance

Adhere to all safety regulations and guidelines, including the use of personal protective equipment and safe work practices.

- Maintain a clean and organized work area, following established procedures and housekeeping standards.

- Report any safety hazards or concerns to supervisors immediately.

Interview Tips

To prepare for an interview for a Box Fabricator position, it is important to demonstrate your skills and experience in the following areas:

1. Technical Skills

Highlight your expertise in operating fabricating machinery, handling materials, and assembling boxes.

- Provide specific examples of projects you have worked on, emphasizing your attention to detail and accuracy.

- Discuss your understanding of different materials and their properties, as well as your ability to work with them effectively.

2. Attention to Detail and Quality Control

Emphasize your commitment to producing high-quality boxes that meet customer specifications.

- Describe your approach to quality control, including your inspection methods and procedures.

- Share examples of projects where your attention to detail resulted in exceptional outcomes.

3. Safety and Compliance

Demonstrate your understanding of safety regulations and your commitment to working safely.

- Discuss your knowledge of specific safety protocols related to box fabrication.

- Provide examples of how you have proactively identified and resolved safety concerns in previous roles.

4. Physical Fitness

Acknowledge that the role requires physical stamina and ability to handle heavy materials.

- Describe your physical condition and your ability to perform the required tasks.

- If you have experience working in physically demanding environments, share relevant examples.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Box Fabricator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Box Fabricator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.