Are you gearing up for a career in Box Inspector? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Box Inspector and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

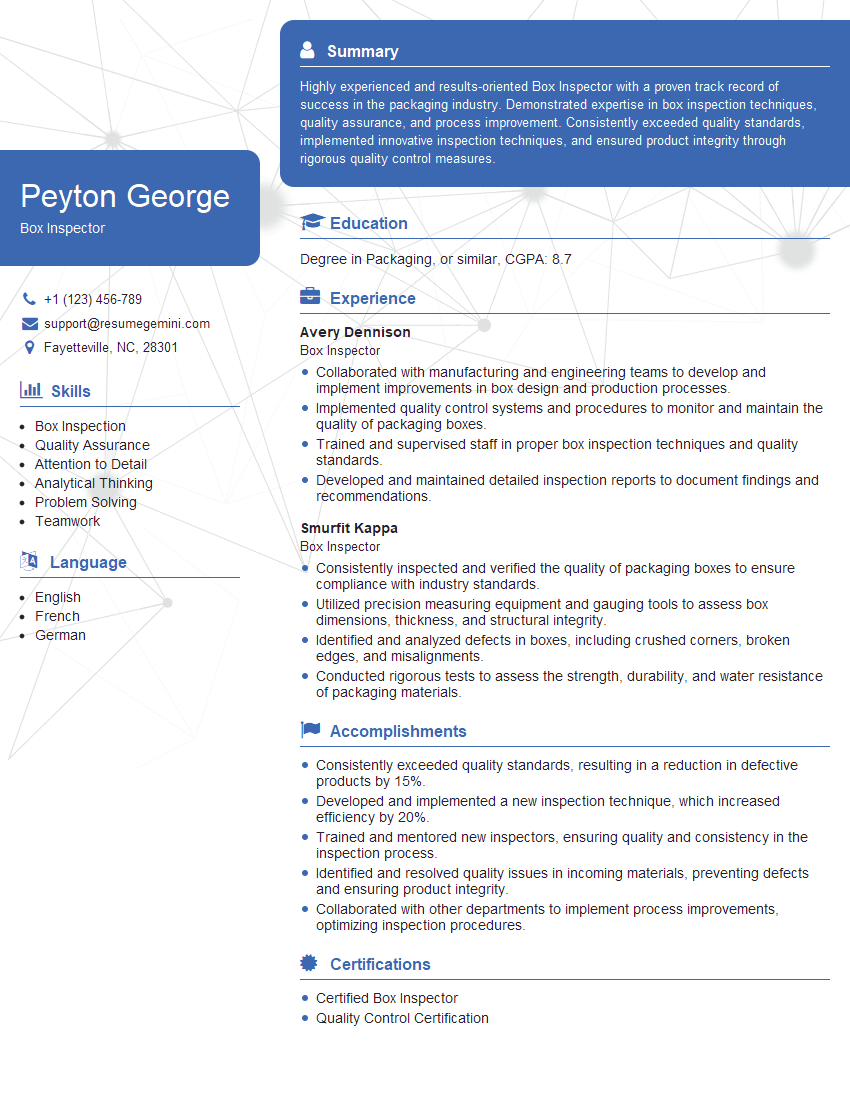

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Box Inspector

1. What are the key responsibilities of a Box Inspector?

As a Box Inspector, my primary responsibilities would encompass:

- Thoroughly inspecting cardboard boxes for defects, ensuring they meet established quality standards.

- Identifying and documenting any imperfections, such as tears, creases, or punctures, using appropriate inspection tools and techniques.

2. How do you ensure accuracy and consistency in your box inspections?

Attention to Detail

- Paying meticulous attention to every detail of the boxes, carefully examining each side for any potential flaws.

- Utilizing standardized inspection checklists to ensure consistency and thoroughness in my assessments.

Proper Lighting and Equipment

- Ensuring optimal lighting conditions to facilitate precise inspections.

- Employing appropriate tools, such as magnifying glasses or bright flashlights, to enhance visibility and detect even the most subtle defects.

3. What types of defects do you typically look for in box inspections?

During box inspections, I primarily focus on identifying the following types of defects:

- Tears: Inspecting for any rips or tears in the cardboard material, regardless of size.

- Creases: Examining for creases or folds that could compromise the box’s structural integrity.

- Punctures: Identifying any holes or punctures that could affect the box’s ability to protect its contents.

- Dents or Crushes: Checking for any dents or crushes that could weaken the box or damage its contents.

- Printing Errors: Verifying the accuracy and clarity of any printed information on the boxes, ensuring it meets the required standards.

4. How do you differentiate between acceptable and unacceptable defects?

To distinguish between acceptable and unacceptable defects, I rely on the following criteria:

- Size and Location: Assessing the size and placement of the defect to determine its potential impact on the box’s functionality.

- Industry Standards: Referring to established industry standards and guidelines to determine the acceptable tolerances for defects.

- Customer Specifications: Considering any specific requirements or specifications provided by the customer regarding acceptable defect levels.

5. What is your process for documenting and reporting defects?

To ensure accurate and timely reporting, I follow a structured process for documenting and reporting defects:

- Defect Identification: Clearly identifying the type and location of each defect observed during the inspection.

- Data Recording: Utilizing inspection forms or electronic systems to record the details of each defect, including its description, size, and location.

- Reporting: Providing timely reports to supervisors or designated personnel, detailing the inspection findings and any corrective actions recommended.

6. How do you handle situations where there is a disagreement about the acceptability of a defect?

In the event of a disagreement, I approach the situation with professionalism and diplomacy:

- Clear Communication: Clearly explaining my assessment of the defect and the reasons behind it.

- Evidence Presentation: Providing supporting evidence, such as photos or measurements, to substantiate my findings.

- Collaboration: Collaborating with supervisors or quality control personnel to reach a consensus on the defect’s acceptability.

7. What are the potential consequences of overlooking defects during box inspections?

Overlooking defects during box inspections can lead to several negative consequences, including:

- Product Damage: Defective boxes can fail to protect their contents adequately, leading to damage or loss of products.

- Customer Dissatisfaction: Receiving damaged products can result in customer dissatisfaction, complaints, and potential loss of business.

- Safety Hazards: Compromised boxes may pose safety hazards if they are used to store or transport hazardous materials.

- Financial Losses: Overlooked defects can lead to product recalls, rework, and replacement costs, resulting in financial losses.

8. How do you stay up-to-date with industry best practices for box inspection?

To maintain my knowledge and skills, I engage in continuous learning and development:

- Industry Seminars and Workshops: Attending industry seminars and workshops to learn about the latest inspection techniques and best practices.

- Online Resources: Utilizing online resources, such as industry publications and webinars, to stay abreast of current trends and advancements.

- Collaboration with Peers: Exchanging knowledge and experiences with colleagues in the field to enhance my understanding of best practices.

9. What is your approach to working in a fast-paced production environment?

In a fast-paced production environment, I maintain efficiency and accuracy by:

- Prioritizing Tasks: Identifying and prioritizing the most critical defects to ensure timely resolution.

- Organized Workflow: Establishing an organized and systematic approach to inspections to minimize errors and maximize productivity.

- Time Management: Effectively managing my time to complete inspections within established deadlines while maintaining high-quality standards.

10. How do you handle the repetitive nature of box inspections?

To maintain focus and motivation in the repetitive nature of box inspections, I employ the following strategies:

- Quality Focus: Staying focused on the importance of my role in ensuring product quality and customer satisfaction.

- Attention to Detail: Maintaining a high level of attention to detail to avoid overlooking any potential defects.

- Regular Breaks: Taking short breaks throughout the day to refresh my focus and prevent monotony.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Box Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Box Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Box Inspector is responsible for inspecting boxes, packages, or other containers to ensure they meet quality standards and specifications.

1. Inspecting Physical Attributes

Inspecting the physical attributes of boxes, such as their size, shape, and color, to ensure they conform to the required specifications.

- Verifying the dimensions and shapes of boxes.

- Checking for any scratches, dents, or other imperfections on the surface of boxes.

2. Checking for Structural Integrity

Checking the structural integrity of boxes to ensure they can withstand the intended weight and handling conditions.

- Testing the durability of boxes by applying pressure or dropping them from a certain height.

- Inspecting boxes for any signs of weakness or damage.

3. Ensuring Quality Standards

Ensuring that boxes meet the required quality standards by checking for any defects or non-conformances.

- Identifying any deviations from the specified standards.

- Reporting any defective or non-compliant boxes to the appropriate personnel.

4. Maintaining Records and Documentation

Maintaining accurate records and documentation of all inspections performed, including the results and any necessary corrective actions.

- Recording the inspection dates, box details, and any observed defects.

- Documenting any corrective measures taken or recommendations made.

Interview Tips

Preparing for a Box Inspector interview requires a thorough understanding of the role’s responsibilities and the ability to effectively communicate your skills and experience.

1. Research the Role and Company

Familiarize yourself with the specific responsibilities and requirements of the Box Inspector position. Research the company’s industry, size, and culture to demonstrate your interest and fit for the role.

2. Highlight Your Quality Control Skills

Emphasize your experience in inspecting products for defects and ensuring quality standards. Mention specific instances where you identified and resolved quality issues effectively.

3. Showcase Your Attention to Detail

Box Inspectors must have a sharp eye for detail. Provide examples that demonstrate your ability to identify even minor defects and accurately assess the quality of products.

4. Discuss Your Problem-Solving Abilities

Box Inspectors often encounter problems with boxes or packaging. Explain your approach to problem-solving and provide examples of how you have resolved issues in the past.

5. Prepare for Common Interview Questions

Practice answering common interview questions tailored to the Box Inspector role, such as “Describe a time you identified a critical defect,” or “How do you maintain accuracy and consistency in your inspections?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Box Inspector interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!