Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Box Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

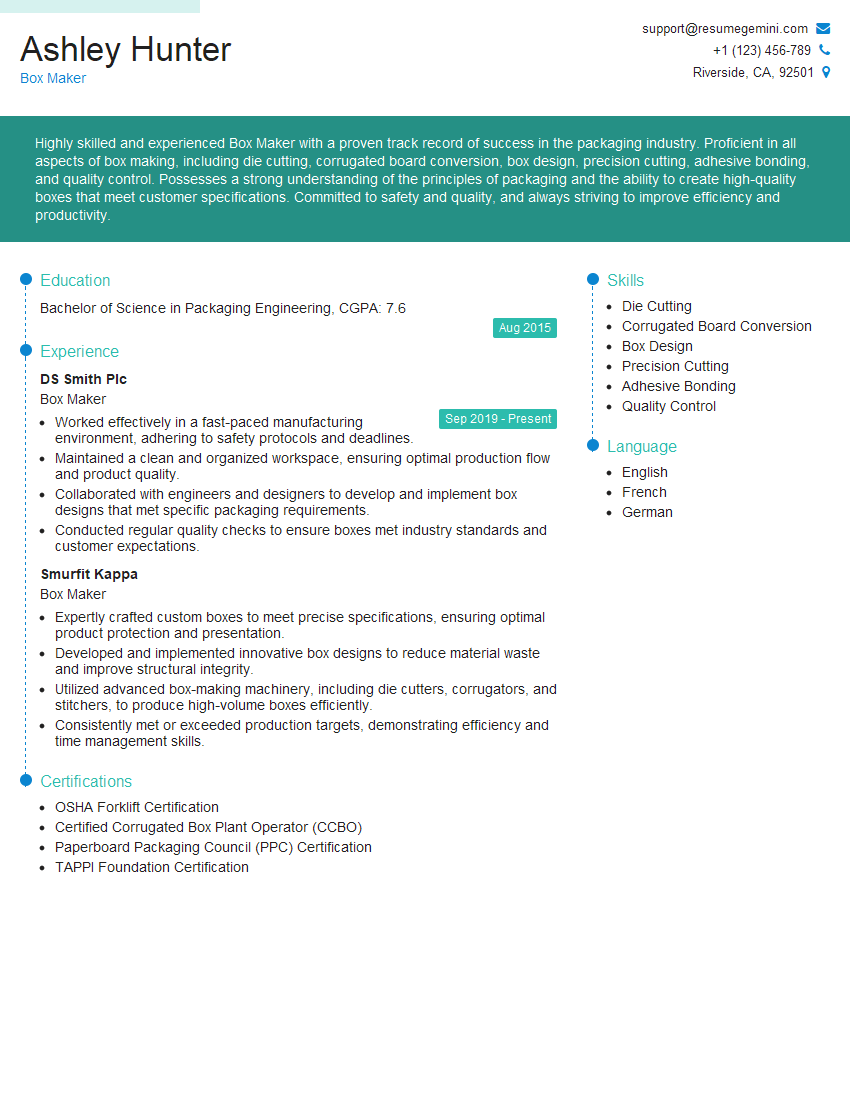

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Box Maker

1. What is the difference between a corrugated box and a solid fiber box?

- Corrugated boxes are made of three layers of paper, with the middle layer being fluted or corrugated. This makes them lightweight and durable.

- Solid fiber boxes are made of a single layer of paperboard, which makes them stronger and more rigid than corrugated boxes.

- Corrugated boxes are more commonly used for shipping products, while solid fiber boxes are more commonly used for storing products.

2. What are the different types of corrugated boxes?

Single-wall corrugated boxes

- Made of one layer of corrugated medium between two linerboards.

- Lightweight and economical.

Double-wall corrugated boxes

- Made of two layers of corrugated medium between three linerboards.

- Stronger and more durable than single-wall boxes.

Triple-wall corrugated boxes

- Made of three layers of corrugated medium between four linerboards.

- The strongest and most durable type of corrugated box.

3. What are the different types of solid fiber boxes?

- Chipboard boxes are made from recycled paper and are a lightweight and inexpensive option.

- Kraft boxes are made from virgin paper and are stronger and more durable than chipboard boxes.

- Corrugated fiberboard boxes are made from a single layer of corrugated cardboard and are stronger than chipboard boxes.

4. What are the different types of box closure methods?

- Regular slotted containers (RSC) are the most common type of box closure method. They have four flaps that meet in the center of the box and are held together with tape or glue.

- Full overlap slotted containers (FOL) have flaps that overlap each other completely. This makes them more secure than RSCs but also more difficult to assemble.

- Half slotted containers (HSC) have two flaps that meet in the center of the box and two flaps that overlap each other. This makes them a good compromise between security and ease of assembly.

5. What are the different types of box printing methods?

- Flexography is a printing method that uses flexible plates to transfer ink to the box. It is a high-speed, low-cost printing method that is well-suited for large print runs.

- Offset printing is a printing method that uses metal plates to transfer ink to the box. It is a high-quality printing method that is well-suited for small print runs.

- Digital printing is a printing method that uses a computer to generate a digital image that is then transferred to the box. It is a versatile printing method that is well-suited for both small and large print runs.

6. What are the different types of box coatings?

- Wax coatings are applied to the box to make it water-resistant and durable.

- Varnish coatings are applied to the box to give it a glossy finish and protect it from scratches.

- Laminate coatings are applied to the box to give it a high-gloss finish and protect it from moisture and abrasion.

7. What are the different types of box sizes?

- The length of the box is the distance from the front of the box to the back of the box.

- The width of the box is the distance from the left side of the box to the right side of the box.

- The height of the box is the distance from the bottom of the box to the top of the box.

8. What are the different types of box weights?

- The bursting strength of a box is the amount of pressure it can withstand before it breaks.

- The edge crush strength of a box is the amount of pressure it can withstand before its edges crush.

- The compression strength of a box is the amount of pressure it can withstand before it collapses.

9. What are the different types of box materials?

- Corrugated cardboard is a strong and lightweight material that is made from multiple layers of paper.

- Solid fiberboard is a strong and durable material that is made from a single layer of paperboard.

- Plastic is a lightweight and durable material that is resistant to moisture and chemicals.

10. What are the different types of box design features?

- Die-cut boxes are boxes that are cut to a specific shape or design.

- Window boxes are boxes that have a clear window that allows the contents of the box to be seen.

- Display boxes are boxes that are designed to be used as a display for products.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Box Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Box Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Box Makers are responsible for constructing and assembling various types of boxes, containers, and packaging materials. Their primary duties include:

1. Box Production

Producing boxes and containers according to specified dimensions and designs.

- Measuring and cutting cardboard or other materials.

- Folding and assembling boxes using glue, tape, or staples.

2. Material Handling

Handling and storing raw materials, such as cardboard, paper, and adhesives.

- Loading and unloading materials.

- Operating forklifts or other equipment to move materials.

3. Quality Control

Inspecting and ensuring the quality of boxes and packaging.

- Checking for defects or errors.

- Repackaging or repairing damaged boxes.

4. Machinery Operation

Operating and maintaining box-making machinery, such as die-cutters, presses, and conveyors.

- Setting up and adjusting machinery.

- Troubleshooting and resolving machine issues.

Interview Tips

To ace your Box Maker interview, consider the following tips:

1. Research the Industry

Familiarize yourself with the packaging industry, box-making processes, and current trends.

- Read industry publications and attend trade shows.

- Learn about different box designs, materials, and equipment.

2. Highlight Your Skills

Emphasize your experience in box production, material handling, quality control, and machinery operation.

- Provide specific examples of your work and quantify your accomplishments.

- Explain how your skills align with the company’s requirements.

3. Be Prepared for Questions

Anticipate common interview questions and prepare thoughtful answers.

- Why are you interested in this role?

- What is your experience in box-making?

- How do you maintain quality standards in box production?

4. Ask Informed Questions

Asking intelligent questions demonstrates your engagement and interest in the position.

- Inquire about the company’s box-making capabilities.

- Ask about the latest advancements in box technology.

5. Practice Your Interview

Rehearse answering common interview questions to improve your confidence and delivery.

- Practice with a friend or family member.

- Record yourself and review your performance.

Next Step:

Now that you’re armed with the knowledge of Box Maker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Box Maker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini