Are you gearing up for a career in Bracer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Bracer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

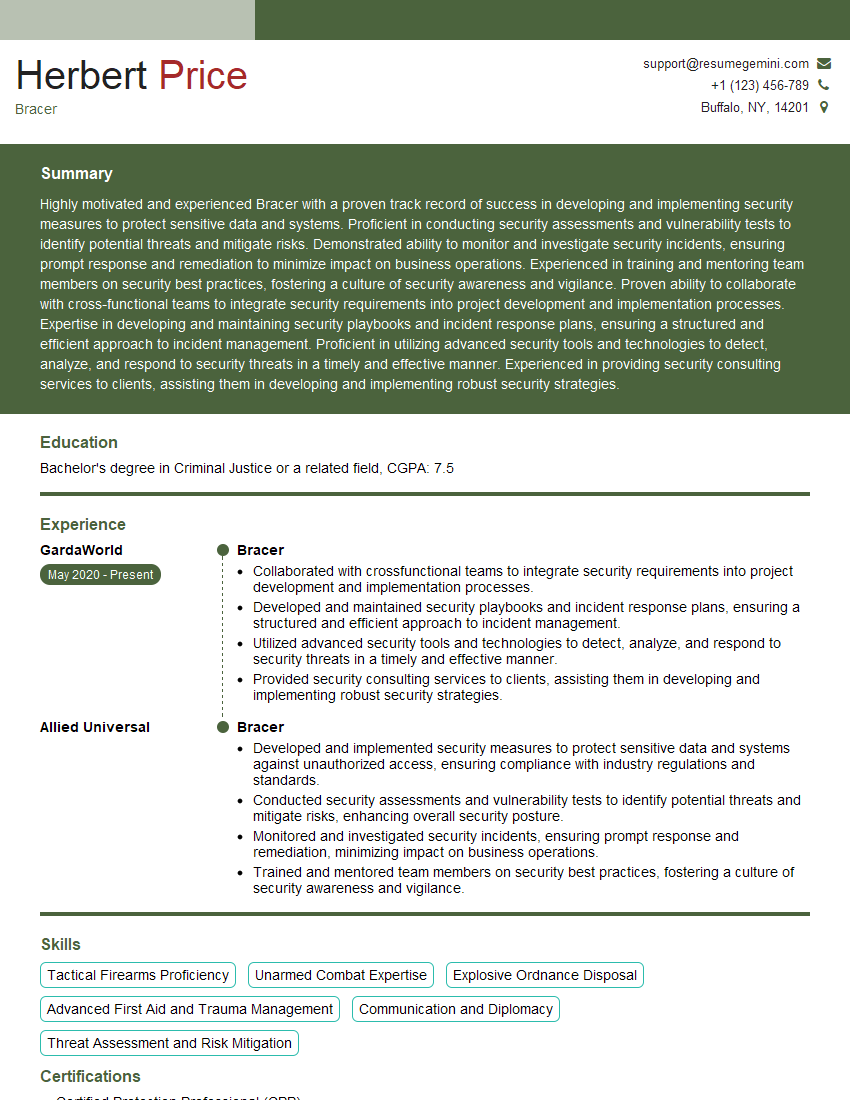

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bracer

1. What are the key responsibilities of a Bracer?

The key responsibilities of a Bracer include:

- Providing support to the team by welding, cutting, and fitting metals and other materials.

- Reading and interpreting blueprints and technical drawings.

- Using a variety of tools and equipment, including welding torches, grinders, and drills.

- Inspecting and testing welds to ensure they meet quality standards.

- Maintaining a clean and organized work area.

2. What types of welding processes are you familiar with?

Arc Welding

- Gas Metal Arc Welding (GMAW)

- Gas Tungsten Arc Welding (GTAW)

- Shielded Metal Arc Welding (SMAW)

- Flux-Cored Arc Welding (FCAW)

Resistance Welding

- Spot Welding

- Projection Welding

- Seam Welding

Other Welding Processes

- Laser Welding

- Electron Beam Welding

- Plasma Arc Welding

3. What is the difference between a butt weld and a fillet weld?

A butt weld is a weld that joins two pieces of metal together at their edges. A fillet weld is a weld that joins two pieces of metal together at their corners.

4. What are the different types of welding joints?

- Butt joint

- Edge joint

- T-joint

- Corner joint

- Lap joint

5. What are the safety precautions that must be taken when welding?

- Wear appropriate protective clothing, including gloves, long sleeves, and a welding helmet.

- Ensure the welding area is well-ventilated.

- Inspect the welding equipment regularly and ensure it is in good working order.

- Never weld near flammable materials.

- Be aware of the potential for electrical hazards.

6. What are the different types of materials that can be welded?

- Steel

- Stainless steel

- Aluminum

- Copper

- Titanium

7. What are the advantages and disadvantages of using a welding robot?

Advantages

- Increased productivity

- Enhanced precision

- Reduced labor costs

- Improved safety

Disadvantages

- High initial investment

- Requires skilled operators

- Limited flexibility

8. What are the different types of welding defects?

- Porosity

- Cracking

- Undercut

- Overcut

- Cold lap

9. How do you inspect a weld?

- Visual inspection

- Non-destructive testing (NDT)

- Destructive testing

10. What are the different types of welding certifications?

- American Welding Society (AWS)

- Canadian Welding Bureau (CWB)

- International Institute of Welding (IIW)

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bracer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bracer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bracers are responsible for providing support and stability to industrial structures, machinery, and equipment. They are typically made of metal or plastic and are designed to withstand high levels of stress and vibration.

1. Design and engineering

Bracers are designed and engineered to meet the specific requirements of the application. This includes considering the load capacity, material properties, and environmental conditions.

- Design and develop bracer solutions for various industrial applications, ensuring structural stability and load distribution.

- Perform stress analysis and evaluate the performance of bracer designs using engineering software.

2. Manufacturing and fabrication

Bracers are manufactured and fabricated using a variety of methods, including cutting, forming, and welding. The manufacturing process must ensure that the bracers meet the required specifications and quality standards.

- Supervise the production and fabrication of bracers according to engineering drawings and specifications.

- Ensure that manufacturing processes adhere to industry standards and quality control procedures.

3. Installation and maintenance

Bracers are installed and maintained by trained technicians. The installation process must be carried out carefully to ensure that the bracers are properly secured and aligned. Bracers should be inspected regularly to ensure that they are in good condition and are performing as intended.

- Provide technical guidance and support during the installation and maintenance of bracers.

- Develop and implement maintenance plans to ensure the longevity and effectiveness of bracer systems.

4. Quality control and safety

Bracers must meet high standards of quality and safety. Bracer manufacturers must have a quality control system in place to ensure that their products meet the required specifications. Bracer installers must be trained in proper safety procedures to ensure that the installation and maintenance of bracers is carried out safely.

- Establish and implement quality control measures to ensure the integrity and reliability of bracer products.

- Conduct regular safety inspections and audits to mitigate risks associated with bracer installation and maintenance.

Interview Tips

In order to ace an interview for a bracer position, it is important to be well-prepared. Here are some tips to help you prepare for your interview:

1. Research the company and the position

Before you go on an interview, it is important to research the company and the position you are applying for. This will help you to understand the company’s culture, values, and goals. It will also help you to understand the specific requirements of the bracer position.

- Visit the company website and social media pages to learn about their mission, values, and recent projects.

- Review the job description carefully to identify the key responsibilities and qualifications.

2. Prepare your answers to common interview questions

There are a number of common interview questions that you are likely to be asked. It is important to prepare your answers to these questions in advance so that you can answer them confidently and succinctly.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with bracers?

- How do you handle stress and pressure?

3. Practice your interviewing skills

The best way to prepare for an interview is to practice. You can practice answering interview questions with a friend, family member, or career counselor. You can also practice by yourself in front of a mirror.

- Set up mock interviews with friends or family members to simulate the real interview experience.

- Record yourself answering interview questions and review the recording to identify areas for improvement.

4. Dress professionally and arrive on time

First impressions matter. Make sure you dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the position and that you respect their time.

- Choose appropriate attire that is clean and pressed.

- Plan your route and transportation in advance to avoid any delays.

5. Be yourself and be confident

The most important thing is to be yourself and be confident. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Confidence is key, but make sure not to come across as arrogant. Remember, they are as interested in you, as you are in them, as this is a two way street.

- Relax and be yourself – authenticity is key.

- Maintain eye contact, speak clearly, and ask questions to show engagement and enthusiasm.

Next Step:

Now that you’re armed with the knowledge of Bracer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Bracer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini