Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Braider Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Braider Operator so you can tailor your answers to impress potential employers.

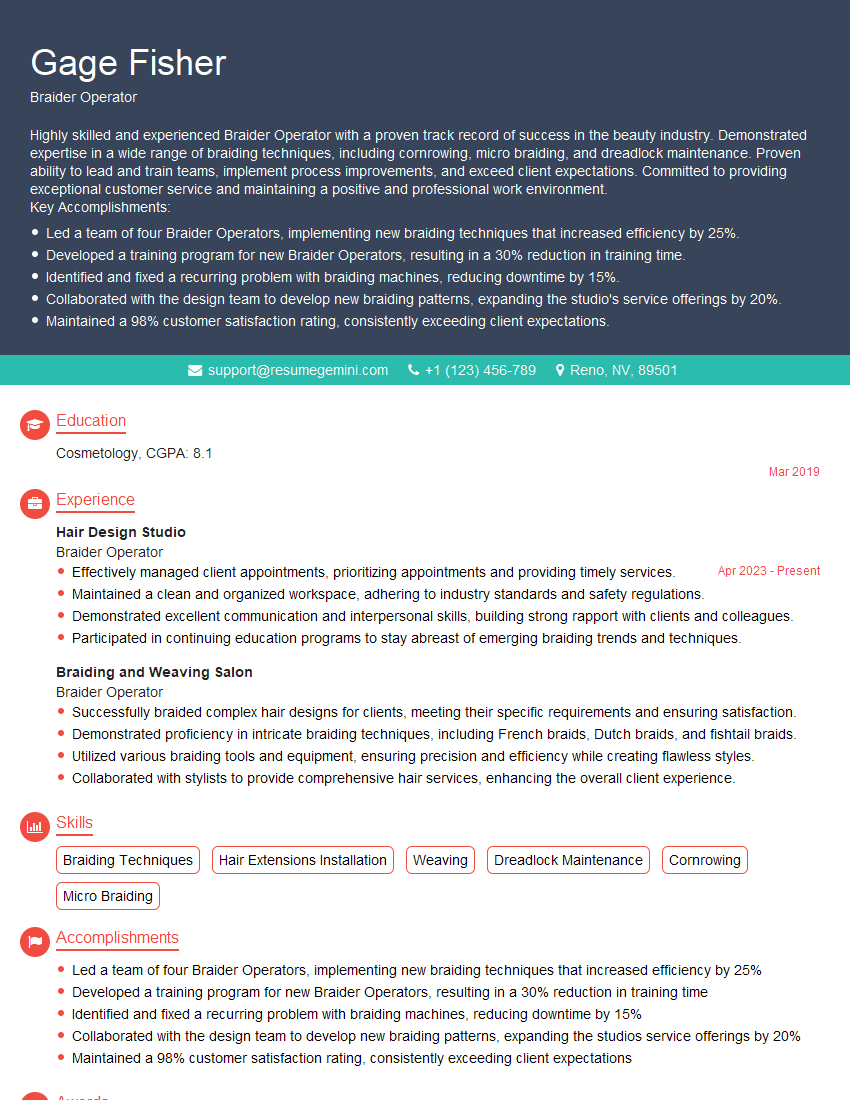

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Braider Operator

1. Explain the process of preparing a braiding machine for operation?

To prepare a braiding machine for operation, I typically follow these steps:

- Inspect the machine for any visible damage or loose parts.

- Clean the machine thoroughly, removing any dirt or debris.

- Lubricate all moving parts according to the manufacturer’s instructions.

- Install the bobbins of yarn or thread onto the machine.

- Thread the yarn or thread through the machine’s guides and tensioners.

- Adjust the machine’s settings, such as the braiding pattern, speed, and tension.

- Run a test braid to ensure that the machine is operating correctly.

2. What are the different types of braiding patterns and how do you determine which pattern to use for a particular application?

Factors to consider when selecting a braiding pattern:

- The desired appearance of the braid

- The type of yarn or thread being used

- The intended use of the braid

Common braiding patterns:

- Plain braid: The simplest braiding pattern, consisting of three strands that are interlaced over and under each other.

- Chevron braid: A variation of the plain braid, where the strands are crossed at an angle to create a zigzag pattern.

- Round braid: A more complex pattern that creates a cylindrical or tubular braid.

- Square braid: Similar to the round braid, but with a square cross-section.

- Fishtail braid: A decorative pattern that resembles a fishtail.

3. How do you troubleshoot common problems that may occur during the braiding process?

To troubleshoot common braiding problems, I systematically check various aspects of the machine and materials:

- Yarn tension: Ensure that the yarn is threaded correctly and that the tension is set appropriately.

- Bobbin alignment: Check if the bobbins are aligned correctly and that the yarn is flowing smoothly.

- Machine speed: Adjust the machine speed to an optimal level for the yarn and braiding pattern.

- Guide and tensioner condition: Inspect the guides and tensioners for any damage or wear that may cause yarn breakage.

- Yarn quality: Examine the yarn for any knots, breaks, or other imperfections that could affect the braiding process.

4. What maintenance tasks are necessary to keep a braiding machine in good working order?

To maintain a braiding machine in good working order, regular maintenance tasks are crucial:

- Cleaning: Regularly remove dust, debris, and yarn remnants from the machine to prevent blockages.

- Lubrication: Lubricate all moving parts according to the manufacturer’s instructions to minimize wear and tear.

- Bobbin inspection: Check bobbins for any damage or wear that could cause yarn breakage.

- Guide and tensioner inspection: Inspect guides and tensioners for any damage or wear that could affect yarn flow.

- Routine adjustments: Periodically adjust the machine’s settings, such as tension and speed, to maintain optimal performance.

5. How do you ensure the quality of the finished braids?

To ensure the quality of the finished braids, I implement the following measures:

- Visual inspection: Regularly inspect the braids during the braiding process to identify any defects or irregularities.

- Tension monitoring: Monitor the yarn tension throughout the process to ensure consistent and high-quality braids.

- Sample testing: Periodically take samples of the braids and test their strength, durability, and appearance.

- Process optimization: Continuously evaluate and optimize the braiding process to improve efficiency and minimize defects.

6. Are you familiar with different types of braiding machines and their capabilities?

Yes, I am familiar with various types of braiding machines and their capabilities:

- Flat braiding machines: Suitable for producing flat braids with a wide range of patterns.

- Circular braiding machines: Used to create tubular or cylindrical braids.

- Lace braiding machines: Specialized machines for producing intricate lace patterns.

- High-speed braiding machines: Designed for high-volume production of braids.

- Computerized braiding machines: Equipped with computer controls for precise pattern creation and automation.

7. How do you handle variations in yarn thickness and quality during the braiding process?

To handle variations in yarn thickness and quality, I take the following steps:

- Yarn selection: I carefully select yarns that are appropriate for the desired braiding pattern and application.

- Tension adjustment: I adjust the machine’s tension settings to accommodate different yarn thicknesses and qualities.

- Monitoring: I continuously monitor the braiding process and make adjustments as needed to ensure consistent braid quality.

- Yarn splicing: If necessary, I splice yarns together to maintain continuity and minimize defects.

8. What safety precautions should be taken when operating a braiding machine?

When operating a braiding machine, it is essential to adhere to the following safety precautions:

- Wear appropriate safety gear, such as gloves and safety glasses.

- Keep hands and loose clothing away from moving parts.

- Inspect the machine regularly for any potential hazards.

- Never attempt to clean or repair the machine while it is running.

- Follow all manufacturer’s safety instructions and guidelines.

9. How do you keep up with advancements in braiding technology and techniques?

To stay updated on advancements in braiding technology and techniques, I employ the following strategies:

- Attend industry conferences and exhibitions.

- Read trade publications and technical journals.

- Participate in online forums and discussion groups.

- Consult with equipment manufacturers and industry experts.

- Conduct research and experimentation to explore new possibilities.

10. What sets you apart from other braider operators and makes you a suitable candidate for this role?

My combination of skills, experience, and dedication sets me apart as an exceptional candidate for this braider operator role:

- Proficient in operating various types of braiding machines.

- Expertise in troubleshooting and resolving braiding issues.

- Strong understanding of braiding patterns and yarn properties.

- Excellent attention to detail and commitment to quality.

- Proven ability to work independently and as part of a team.

- Eager to learn new technologies and techniques.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Braider Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Braider Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Braider Operator plays a crucial role in the manufacturing process, operating and maintaining braiding machines to produce various types of braided products. Their key responsibilities include:

1. Machine Operation

Operate braiding machines according to established procedures, ensuring efficient and accurate production.

- Monitor machine performance and make necessary adjustments to optimize production.

- Perform routine maintenance and troubleshooting to prevent breakdowns and ensure smooth operation.

2. Product Quality Control

Inspect braided products for defects and ensure they meet quality standards.

- Identify and rectify errors or imperfections in the braiding process.

- Maintain accurate records of product quality and production output.

3. Materials Handling

Load and unload materials, such as yarns or threads, into the braiding machines.

- Ensure proper inventory management and minimize material waste.

- Handle and store materials safely to prevent damage or contamination.

4. Equipment Maintenance

Perform basic maintenance and cleaning of braiding machines and related equipment.

- Lubricate and adjust machines as per manufacturer’s specifications.

- Replace worn or damaged components to ensure optimal machine performance.

Interview Tips

To ace the Braider Operator interview, prepare by focusing on these key aspects:

1. Research the Company and Industry

Understand the company’s history, products, and industry trends. Research the specific manufacturing processes and equipment used in the braiding industry.

- Visit the company website and LinkedIn page to gather information.

- Read industry publications and articles to stay updated on the latest developments.

2. Practice Answering Common Interview Questions

Prepare for common interview questions related to your skills and experience. Practice answering them clearly and concisely, highlighting your strengths and qualifications.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Provide specific examples from your previous roles to demonstrate your abilities.

3. Emphasize Your Technical Skills

Highlight your proficiency in operating and maintaining braiding machines. Explain your understanding of the machines’ mechanics, troubleshooting procedures, and preventive maintenance techniques.

- Quantify your results whenever possible, using metrics such as production output or machine uptime.

- Showcase your commitment to continuous learning and staying updated on new technologies.

4. Demonstrate Attention to Detail

Emphasize your strong attention to detail and ability to identify and rectify errors. Explain how you ensure product quality throughout the braiding process.

- Provide examples of how you implemented quality control measures or resolved product defects.

- Describe your commitment to maintaining a clean and organized work environment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Braider Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!