Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Braiding Machine Tender interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Braiding Machine Tender so you can tailor your answers to impress potential employers.

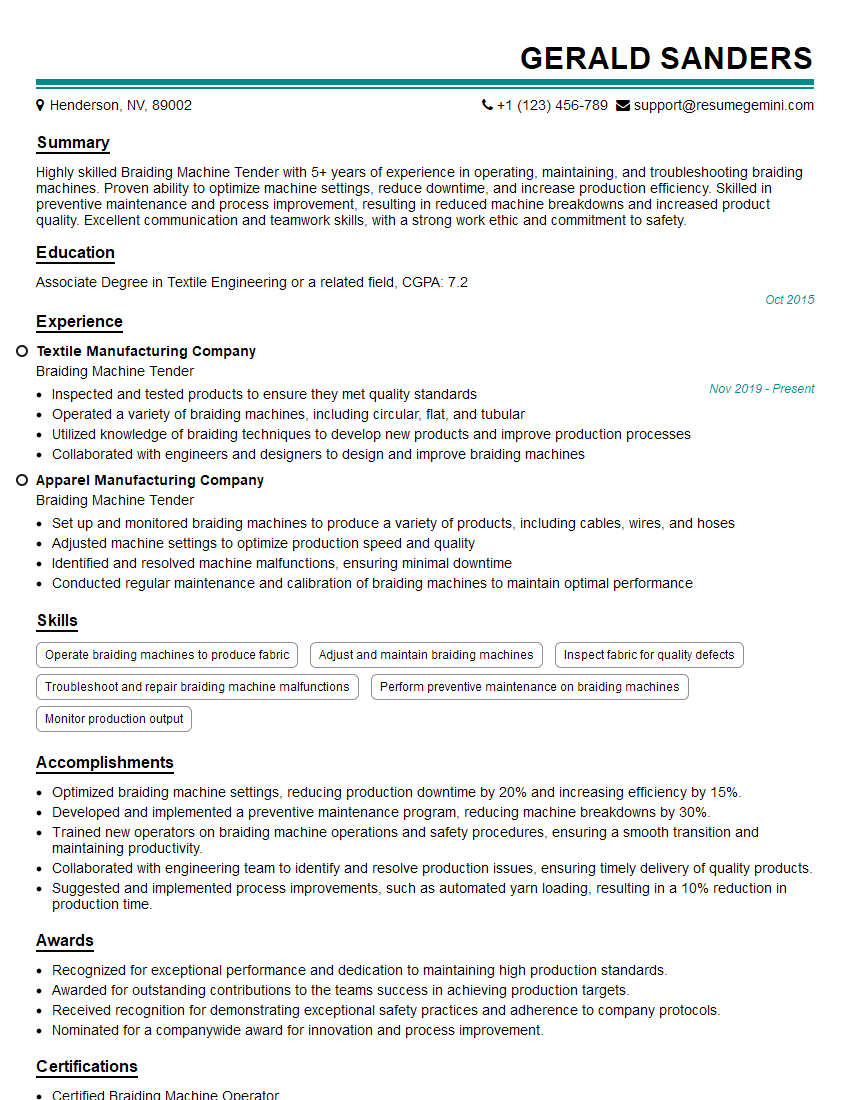

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Braiding Machine Tender

1. What are the different types of braiding machines you have worked on?

I have extensive experience operating various types of braiding machines, including:

- Single-carrier braiding machines

- Multi-carrier braiding machines

- Cylindrical braiding machines

- Tubular braiding machines

- Flat braiding machines

2. How do you ensure the production of high-quality braids?

Quality Control and Monitoring

- Regular machine calibration and maintenance

- Yarn tension monitoring to prevent breakage

- Visual inspection of braid consistency throughout the process

Process Optimization

- Adjustment of machine parameters (e.g., speed, tension) based on yarn properties

- Fine-tuning of braiding angles to achieve desired braid characteristics

- Implementation of statistical process control techniques to identify and address variations

3. Describe the process of troubleshooting common braiding machine issues.

When encountering braiding machine issues, I follow a systematic troubleshooting process:

- Identify the problem: Note the specific symptom (e.g., broken yarn, irregular braiding)

- Inspect the machine: Check yarn tension, machine settings, and mechanical components.

- Test and isolate the cause: Conduct tests (e.g., yarn strength, machine calibration) to narrow down the issue.

- Implement the solution: Make necessary adjustments (e.g., tension adjustment, component replacement).

- Evaluate the results: Confirm if the problem has been resolved and make further adjustments as needed.

4. What safety precautions do you take when operating braiding machines?

I prioritize safety by adhering to the following precautions:

- Wear appropriate safety gear (e.g., gloves, safety glasses)

- Secure loose clothing and hair

- Inspect the machine before starting operations

- Follow established safety protocols

- Handle yarns and sharp objects with care

- Report any potential hazards immediately

5. How do you calculate the efficiency and productivity of a braiding machine?

I use the following metrics to evaluate braiding machine efficiency and productivity:

- Machine uptime: Percentage of time the machine is operating without interruptions or downtime

- Production output: Length or weight of braids produced per unit of time

- Waste percentage: Amount of yarn or materials wasted during the braiding process

I analyze these metrics regularly to identify areas for improvement and optimize machine performance.

6. What maintenance tasks do you perform on braiding machines to ensure their smooth operation?

I conduct regular maintenance tasks to keep braiding machines in optimal condition:

- Daily: Lubricate moving parts, clean yarn guides, check tension settings.

- Weekly: Inspect belts and pulleys, clean sensors, calibrate the machine.

- Monthly: Replace worn components, conduct in-depth inspection, adjust tension.

- Quarterly: Perform comprehensive maintenance, including spindle alignment, electrical checks.

7. How do you set up a braiding machine for a new product?

When setting up a braiding machine for a new product, I follow these steps:

- Review the product specifications and yarn properties

- Calculate appropriate machine parameters (e.g., speed, tension, braiding angle)

- Install and adjust braiding heads and yarn carriers

- Thread the yarns and set up the tension system

- Conduct trial runs and make necessary adjustments

- Obtain and document optimal machine settings for the new product

8. How do you handle yarn breakage during the braiding process?

I handle yarn breakage during the braiding process efficiently:

- Identify the broken yarn: Locate the specific carrier or guide where the breakage occurred.

- Stop the machine: Immediately halt the braiding process to prevent further damage.

- Rethread the yarn: Replace the broken yarn and ensure proper tensioning.

- Check other yarns: Inspect adjacent yarns to ensure they are intact and adjust tension as needed.

- Restart the machine: Once the broken yarn is replaced, resume the braiding process.

9. What are the potential causes of irregular or uneven braiding?

Irregular or uneven braiding can result from several factors:

- Inconsistent yarn tension

- Improper braiding angle or machine calibration

- Yarn defects or variations

- Misaligned or worn components

- Environmental factors (e.g., temperature, humidity)

10. Describe your experience in using braiding machines to produce specialized or custom braids.

I have extensive experience in producing specialized and custom braids using braiding machines:

- Developed and optimized processes for braiding complex patterns and structures.

- Utilized different yarns and materials to create unique and functional braids.

- Collaborated with designers and engineers to meet specific product requirements.

- Successfully produced custom braids for various industries, including medical, automotive, and aerospace.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Braiding Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Braiding Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Braiding Machine Tenders supervise and operate braiding machines that interlace strands of wire, yarn, or other materials to create braids, cords, and other products.

1. Machine Supervision

Monitor braiding machines during operation, ensuring they run smoothly and efficiently.

- Adjust machine settings, such as speed, tension, and temperature, to optimize production.

- Identify and resolve malfunctions, performing minor repairs and maintenance.

2. Material Preparation

Prepare materials, such as wire strands, yarn, and thread, for braiding by winding them onto spools or bobbins.

- Inspect materials for defects and ensure they meet quality standards.

- Load prepared materials onto braiding machines.

3. Quality Control

Monitor the quality of braided products, ensuring they meet specifications.

- Inspect products for defects, such as broken strands, uneven braiding, or incorrect dimensions.

- Adjust machine settings or materials as needed to improve product quality.

4. Production Records

Maintain production records, including machine run times, material usage, and product output.

- Monitor production against targets and identify areas for improvement.

- Collaborate with supervisors and other team members to enhance efficiency and productivity.

Interview Tips

Preparation is key to ace an interview for the position of Braiding Machine Tender. Here are some tips that can help you stand out from other candidates:

1. Research the Company and Position

Thoroughly research the company you’re applying to, including their history, products/services, and industry reputation. Understand the specific responsibilities of the Braiding Machine Tender position and how it aligns with your skills and experience.

2. Practice Your Answers

Anticipate common interview questions related to braiding machines, quality control, production, and teamwork. Prepare thoughtful and concise answers that demonstrate your knowledge and abilities.

3. Highlight Your Skills

Emphasize your technical skills in operating braiding machines, including your ability to identify and resolve malfunctions. Showcase your attention to detail and commitment to producing high-quality products.

4. Showcase Your Experience

Provide specific examples from your previous work experience that demonstrate your proficiency in braiding machine operation, material preparation, quality control, and production optimization.

5. Be Enthusiastic and Confident

Show the interviewer that you’re passionate about working with braiding machines and are eager to contribute to the company’s success. Maintain eye contact, speak clearly, and convey your enthusiasm for the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Braiding Machine Tender interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.