Are you gearing up for an interview for a Brake Liner position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Brake Liner and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

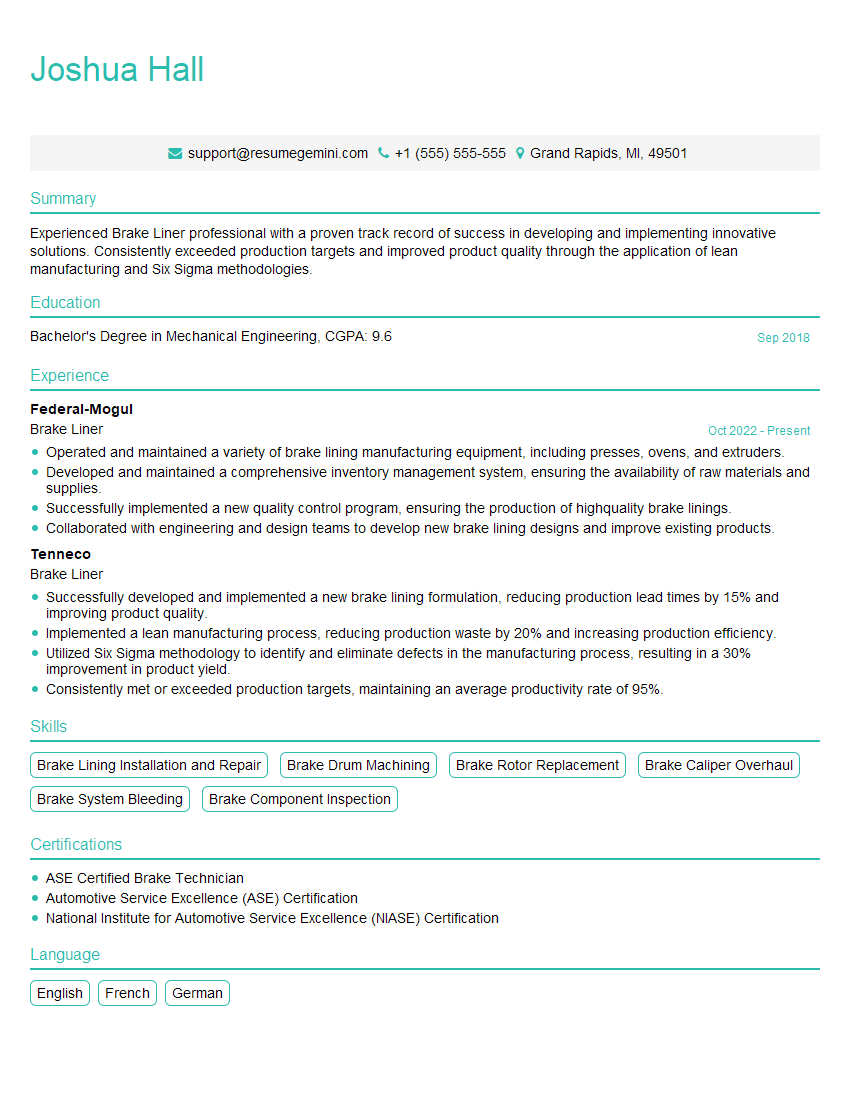

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Brake Liner

1. Explain the role and function of the brake lining in the braking system of a vehicle?

- The brake lining is a crucial component of the braking system, responsible for converting friction into heat to slow down or stop a vehicle.

- When the brake pedal is applied, the brake pads press against the brake rotors or drums, creating friction.

- This friction generates heat, which is dissipated into the air and helps reduce the vehicle’s speed.

2. What are the different types of brake linings available? Discuss their advantages and disadvantages?

Organic brake linings

- Made from non-metallic materials such as rubber, resin, and fiberglass.

- Advantages: quiet operation, smooth braking, environmentally friendly.

- Disadvantages: lower durability, higher fade resistance.

Semi-metallic brake linings

- Combine organic materials with metal particles such as iron, copper, or steel.

- Advantages: longer lifespan, better braking performance under higher temperatures.

- Disadvantages: more noise, potential for increased wear on rotors.

Ceramic brake linings

- Composed of ceramic fibers and metal particles.

- Advantages: excellent durability, high-temperature resistance, low noise.

- Disadvantages: more expensive, potential for higher wear on rotors.

3. Describe the key factors that affect the performance of brake linings?

- Friction coefficient: Measures the amount of grip between the brake lining and the rotor/drum.

- Fade resistance: Indicates the lining’s ability to maintain friction under high temperatures.

- Wear resistance: Determines the lining’s durability and lifespan.

- Noise level: Refers to the amount of noise produced during braking.

- Environmental friendliness: Considers the impact of the lining on the environment.

4. Explain the process of testing and evaluating the performance of brake linings?

- Dyno testing: Simulates real-world driving conditions to assess friction coefficient, fade resistance, and wear.

- Road testing: Conducts actual vehicle tests to evaluate overall braking performance.

- Material analysis: Examines the lining’s composition, microstructure, and properties.

- Durability testing: Assesses the lining’s resistance to wear and tear over extended periods.

5. What are the latest trends in brake lining technology?

- Development of low-dust and noise-reducing linings.

- Advancements in friction materials for improved performance and durability.

- Integration of sensors into brake linings to monitor wear and performance.

- Research on environmentally friendly materials and manufacturing processes.

6. Describe the role of a brake lining engineer in the automotive industry?

- Designing and developing new brake lining formulations.

- Testing and evaluating brake lining performance.

- Working with vehicle manufacturers to optimize braking systems.

- Addressing technical issues and providing support to customers.

7. What are the challenges and opportunities in the brake lining industry?

Challenges

- Meeting increasingly stringent performance and environmental regulations.

- Balancing performance, durability, and cost.

- Keeping up with technological advancements and innovation.

Opportunities

- Developing new materials and technologies to improve braking performance.

- Collaborating with vehicle manufacturers to optimize braking systems.

- Addressing environmental concerns through sustainable manufacturing and materials.

8. Describe the key differences between disc brake linings and drum brake linings?

Disc brake linings

- Attaches to a caliper and presses directly onto the spinning brake rotor.

Drum brake linings

- Located inside a brake drum and expands outward to create friction against the inner surface of the drum.

9. What are the common causes of brake lining failure?

- Excessive wear due to extensive use.

- Extreme heat caused by heavy braking or overloading.

- Contamination by fluids or debris.

- Defective installation or maintenance.

- Corrosion or rust due to moisture exposure.

10. Describe the importance of proper brake lining maintenance and replacement?

- Ensures optimal braking performance and vehicle safety.

- Prevents premature brake failure and costly repairs.

- Reduces noise and vibration during braking.

- Maintains proper pad-to-rotor/drum contact for effective braking.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Brake Liner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Brake Liner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Brake Liners play a crucial role in automotive safety systems, ensuring the smooth and efficient operation of braking mechanisms. Their primary responsibilities revolve around developing, testing, and manufacturing high-quality brake liners that meet specific performance and safety standards.

1. Product Development and Innovation

In collaboration with design engineers, Brake Liners contribute to the development and improvement of new brake liner formulations. They conduct research, analyze data, and test different materials to optimize friction coefficients, wear resistance, and thermal stability.

- Conduct thorough market research to identify industry trends and customer needs.

- Develop and evaluate new brake liner formulations using advanced testing methods and material analysis techniques.

2. Quality Control and Assurance

Brake Liners ensure the quality and reliability of brake liners throughout the manufacturing process. They establish and implement quality control measures, monitor production lines, and conduct rigorous testing to verify the performance and safety of brake liners.

- Establish and maintain quality control standards for raw materials, manufacturing processes, and finished products.

- Conduct regular inspections and audits to ensure adherence to quality guidelines.

3. Testing and Evaluation

Brake Liners conduct comprehensive testing and evaluation of brake liners to assess their performance, durability, and compliance with industry regulations. They utilize specialized equipment and testing methodologies to analyze friction coefficients, wear rates, and thermal properties.

- Design and execute performance tests to evaluate braking torque, response time, and fade resistance.

- Conduct durability tests to assess wear resistance and the ability to withstand extreme conditions.

4. Customer Support and Technical Expertise

Brake Liners provide technical support and guidance to customers, including automotive manufacturers, distributors, and end-users. They share knowledge about brake liner products, application recommendations, and troubleshooting techniques.

- Provide technical assistance and problem-solving to customers experiencing issues with brake liners.

- Conduct training sessions and seminars on brake liner technology and best practices.

Interview Tips

Preparing for a Brake Liner interview requires a combination of technical knowledge, industry expertise, and strong communication skills. Here are some tips to help candidates ace the interview:

1. Research the Industry and Company

In-depth knowledge of the automotive industry and the specific company you are applying to is essential. Familiarize yourself with the latest trends in brake liner technology, industry regulations, and the company’s product portfolio.

- Review industry publications, attend conferences, and stay up-to-date with emerging technologies.

- Thoroughly research the company’s website, annual reports, and press releases to understand their business model, products, and values.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in brake liner development, testing, and quality control. Share specific examples of projects you have worked on, highlighting your ability to solve complex problems and achieve positive outcomes.

- Quantify your accomplishments whenever possible, using metrics such as performance improvements, cost savings, or successful product launches.

- Showcase your understanding of industry standards, testing methodologies, and quality assurance practices.

3. Prepare for Technical Questions

Expect the interviewer to ask detailed technical questions about brake liner materials, performance characteristics, and testing procedures. Prepare by reviewing the fundamentals of friction, wear, and thermal analysis techniques.

- Brush up on your knowledge of brake liner formulations, friction modifiers, and material properties.

- Be ready to discuss different types of brake testing, such as dynamometer tests, fade tests, and durability tests.

4. Demonstrate Communication and Interpersonal Skills

Effective communication and interpersonal skills are crucial for Brake Liners. During the interview, articulate your thoughts clearly, actively listen to the interviewer’s questions, and ask thoughtful questions that demonstrate your interest.

- Practice your answers to common interview questions related to your experience, skills, and career goals.

- Be confident and enthusiastic, and convey your passion for brake liner technology and automotive safety.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Brake Liner interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!