Feeling lost in a sea of interview questions? Landed that dream interview for Brake Lining Driller but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Brake Lining Driller interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

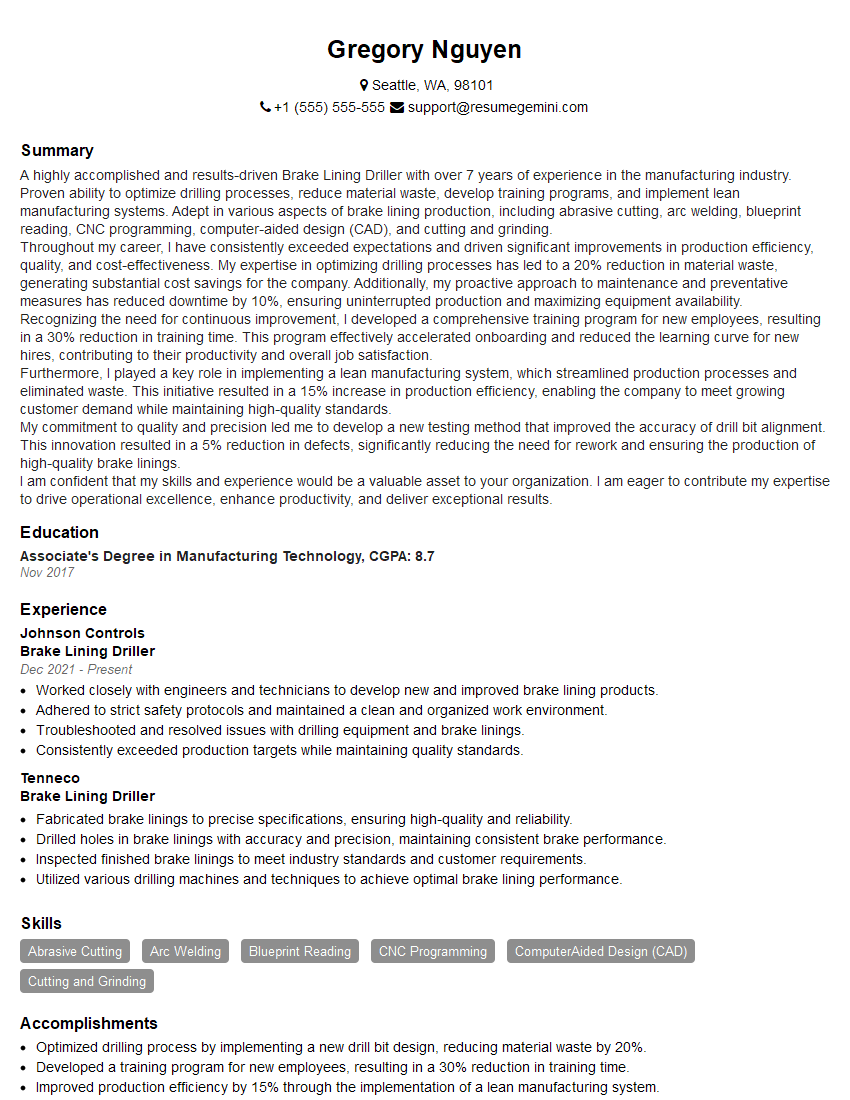

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Brake Lining Driller

1. What are the different types of brake lining materials you have experience working with?

- Organic brake linings: These are made from a mixture of organic fibers, such as cotton, paper, and rubber. They are the most common type of brake lining used in passenger cars.

- Semi-metallic brake linings: These are made from a mixture of organic fibers and metal particles. They offer better performance than organic brake linings, but they are also more expensive.

- Ceramic brake linings: These are made from a mixture of ceramic fibers and metal particles. They offer the best performance of all types of brake linings, but they are also the most expensive.

2. What are the different types of brake drilling machines?

CNC drilling machines

- These are computer-controlled machines that can drill holes with great accuracy and precision.

- They are typically used for high-volume production applications.

Manual drilling machines

- These are operated by hand and require the operator to have a high level of skill and experience.

- They are typically used for low-volume production applications or for drilling holes in large or complex parts.

3. What are the key factors to consider when selecting a drill bit for brake lining?

- The type of brake lining material

- The thickness of the brake lining

- The desired hole size

- The drilling machine being used

4. What are the safety precautions that should be taken when drilling brake linings?

- Wear appropriate safety gear, including safety glasses, gloves, and a dust mask.

- Ensure that the drilling machine is properly grounded.

- Use sharp drill bits and replace them regularly.

- Do not drill into the backing plate of the brake lining.

- Drill in a well-ventilated area.

5. What are the common defects that can occur when drilling brake linings?

- Holes that are too large or too small

- Holes that are not drilled in the correct location

- Holes that are not drilled to the correct depth

- Cracks or other damage to the brake lining

6. How do you ensure that the brake linings are drilled to the correct specifications?

- Use a drill bit of the correct size.

- Drill the holes to the correct depth.

- Drill the holes in the correct location.

- Inspect the brake linings after drilling to ensure that there are no defects.

7. What is the difference between a countersink and a counterbore?

- A countersink is used to create a tapered hole for the head of a screw or bolt.

- A counterbore is used to create a flat-bottomed hole for the head of a screw or bolt.

8. What is the purpose of using a lubricant when drilling brake linings?

- To reduce friction between the drill bit and the brake lining

- To prevent the drill bit from overheating

- To improve the quality of the drilled hole

9. What are the different methods of deburring brake linings?

- Manual deburring: This is done by hand using a file or a deburring tool.

- Mechanical deburring: This is done using a machine that removes the burrs from the brake linings.

- Chemical deburring: This is done using a chemical solution that dissolves the burrs from the brake linings.

10. What are the quality control checks that should be performed on brake linings after drilling?

- Inspect the brake linings for any defects, such as cracks or other damage.

- Measure the holes to ensure that they are the correct size and depth.

- Ensure that the brake linings are properly deburred.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Brake Lining Driller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Brake Lining Driller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Brake Lining Drillers are reliable individuals who take pride in their work and possess a strong attention to detail. They operate various drilling machines and tools to create holes in brake linings, ensuring that they meet specifications and perform as intended. Their responsibilities include:

1. Drilling Operations

Drill holes in brake linings using specialized drilling machines, following precise specifications and blueprints.

- Set up and calibrate drilling machines to meet specific hole sizes, depths, and patterns.

- Inspect brake linings before drilling to ensure they are free of defects and meet quality standards.

2. Quality Control

Maintain high levels of quality by conducting regular inspections of drilled brake linings.

- Measure and verify hole dimensions, depths, and spacing against specifications using precision measuring tools.

- Identify and correct any deviations from specifications, ensuring that brake linings meet performance and safety requirements.

3. Machine Maintenance

Keep drilling machines and equipment in optimal condition for efficient operations.

- Perform routine maintenance tasks, including cleaning, lubrication, and adjustments.

- Identify and address minor machine malfunctions, preventing downtime and ensuring smooth production processes.

4. Workplace Safety

Adhere to all health and safety regulations to maintain a safe and hazard-free work environment.

- Wear appropriate personal protective equipment (PPE) such as goggles, gloves, and safety shoes.

- Follow established safety protocols, including proper handling of drilling equipment and materials.

Interview Tips

To ace your interview and showcase your qualifications as a Brake Lining Driller, follow these tips:

1. Research the Company and Position

Before the interview, thoroughly research the company’s background, industry, and specific role you are applying for. This knowledge will enable you to ask informed questions and demonstrate your interest in the opportunity.

- Review the company’s website, social media profiles, and industry publications.

- Identify key individuals within the company and research their roles.

2. Prepare Examples of Your Skills

Quantify and provide specific examples of your drilling operations, quality control, machine maintenance, and safety practices. Use the STAR method (Situation, Task, Action, Result) to highlight your accomplishments.

- Describe a situation where you successfully identified and corrected a drilling machine malfunction, resulting in increased productivity.

- Share an example of how you implemented a new quality control process that reduced defect rates significantly.

3. Highlight Your Attention to Detail

Brake Lining Drillers must possess an exceptional eye for detail. Emphasize your meticulous approach to inspecting and measuring brake linings, ensuring adherence to specifications.

- Explain how you use precision measuring tools to verify hole dimensions accurately.

- Discuss a scenario where your attention to detail led to the identification of a potential safety hazard, preventing an accident.

4. Share Your Passion for Safety

Safety is paramount in manufacturing environments. Convey your understanding of health and safety regulations and your commitment to maintaining a safe workplace.

- Describe your experience in following proper PPE protocols and safety guidelines.

- Share an instance where you actively participated in safety training or initiatives, demonstrating your proactive approach to risk management.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Brake Lining Driller interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!