Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Brass Cutter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

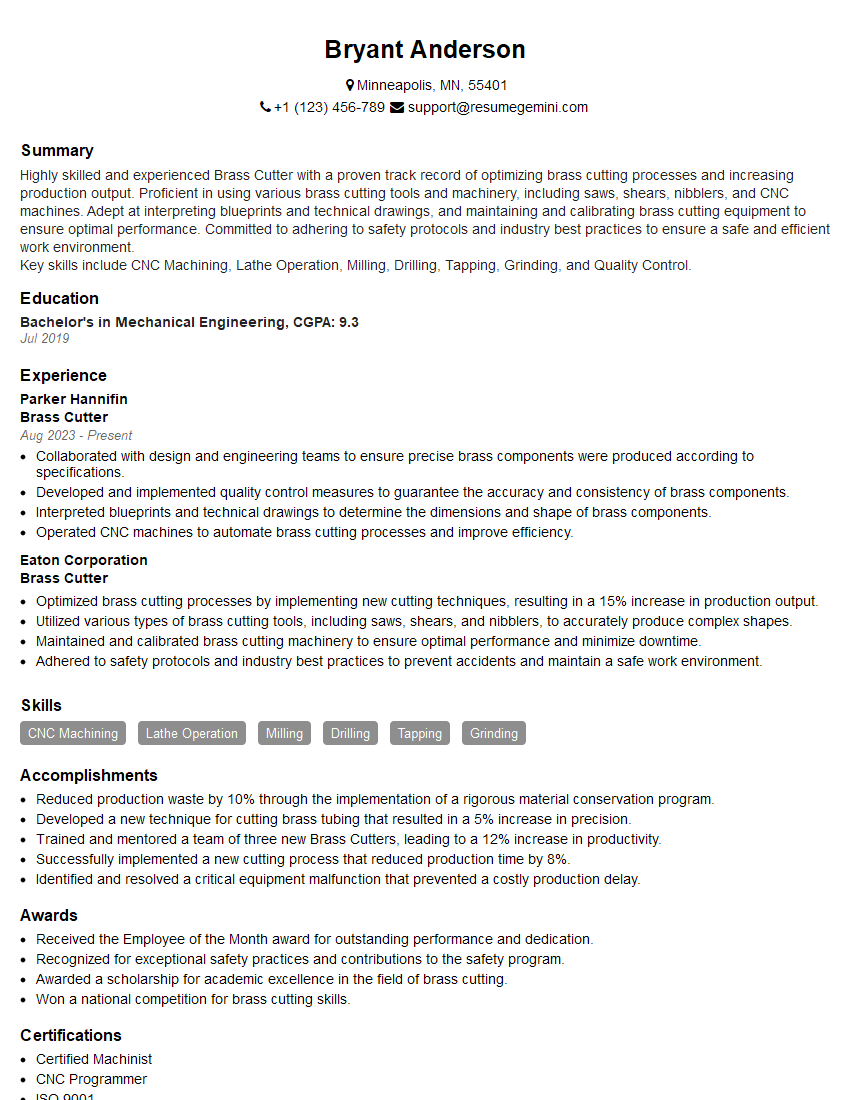

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Brass Cutter

1. What are the different types of brass cutters and their uses?

There are generally two types of brass cutters:

- Tubing cutters are used to cut brass tubing. They are typically made of hardened steel and have a sharp cutting blade that is rotated around the tubing to cut it.

- Sheet cutters are used to cut brass sheet metal. They are typically made of high-carbon steel and have a sharp cutting edge that is used to shear the metal.

2. What are the safety precautions that should be taken when using a brass cutter?

Always wear safety glasses

- Make sure the brass cutter is in good working condition and that the blade is sharp.

- Secure the brass material firmly in place before cutting it.

- Use a cutting fluid to lubricate the blade and reduce friction.

- Keep your hands away from the cutting blade.

- Never attempt to cut brass that is too thick or hard for the cutter.

Properly maintain the cutter

- Clean the brass cutter regularly to remove any metal shavings or debris.

- Sharpen the blade when it becomes dull.

- Store the brass cutter in a safe place when not in use.

3. How do you choose the right brass cutter for a particular job?

- Consider the thickness and hardness of the brass material that you will be cutting.

- Choose a brass cutter that is designed for the specific type of brass that you will be cutting.

- Consider the size and shape of the brass material that you will be cutting.

- Read reviews of different brass cutters to see what other users have said about them.

4. What are some common problems that can occur when using a brass cutter and how can they be solved?

- The blade becomes dull. This can be solved by sharpening the blade.

- The brass material is too thick or hard for the cutter. This can be solved by using a more powerful cutter.

- The brass material is not secured firmly in place. This can be solved by using a clamp or vise to hold the material in place.

- The cutting fluid is not applied properly. This can be solved by applying the cutting fluid more frequently.

5. What are some tips for getting the best results when using a brass cutter?

- Use a sharp blade.

- Secure the brass material firmly in place.

- Apply cutting fluid to the blade.

- Cut slowly and evenly.

- Be patient.

6. How do you maintain a brass cutter?

- Clean the brass cutter regularly to remove any metal shavings or debris.

- Sharpen the blade when it becomes dull.

- Lubricate the moving parts of the cutter.

- Store the brass cutter in a safe place when not in use.

7. What are the different types of brass and how do they affect the cutting process?

Red brass

- Red brass is a copper-zinc alloy that contains approximately 85% copper and 15% zinc.

- It is the most common type of brass and is used in a wide variety of applications.

- Red brass is relatively soft and easy to cut.

Yellow brass

- Yellow brass is a copper-zinc alloy that contains approximately 65% copper and 35% zinc.

- It is harder and stronger than red brass, but is also more difficult to cut.

- Yellow brass is often used in applications where strength is required, such as in musical instruments and jewelry.

White brass

- White brass is a copper-zinc-nickel alloy that contains approximately 55% copper, 40% zinc, and 5% nickel.

- It is the hardest and strongest type of brass, but is also the most difficult to cut.

- White brass is often used in applications where high strength and corrosion resistance are required, such as in marine hardware and chemical processing equipment.

8. What are the advantages and disadvantages of using a brass cutter?

Advantages

- Brass cutters are relatively inexpensive.

- They are easy to use.

- They can cut brass quickly and accurately.

Disadvantages

- Brass cutters can only cut brass.

- They can be dangerous if they are not used properly.

9. What are the different ways to cut brass?

- Brass can be cut using a brass cutter.

- It can also be cut using a hacksaw, a band saw, or a circular saw.

- The best method for cutting brass depends on the thickness and hardness of the brass, as well as the desired accuracy of the cut.

10. What are some tips for cutting brass safely?

- Always wear safety glasses.

- Use a sharp blade.

- Secure the brass material firmly in place.

- Cut slowly and evenly.

- Be patient.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Brass Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Brass Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Brass Cutter plays a critical role in the fabrication process by expertly cutting and shaping brass materials. They ensure precise and efficient cutting operations, contributing to the overall quality and productivity of the manufacturing unit.

1. Brass Cutting and Shaping

Use specialized cutting tools, such as band saws, circular saws, and shears, to cut brass into desired shapes and dimensions.

2. Measuring and Marking

Measure and mark brass materials accurately using measuring tapes, rulers, and other tools to guide cutting operations.

3. Machine Operation and Maintenance

Operate and maintain cutting machines, ensuring they are calibrated and running smoothly to achieve optimal cutting results.

4. Material Handling and Storage

Safely handle and store brass materials, adhering to established inventory management procedures.

5. Quality Control and Inspection

Inspect cut brass parts for precision and quality, ensuring they meet specified tolerances and standards.

6. Safety Compliance

Follow established safety protocols and wear appropriate safety gear to minimize risks associated with cutting operations.

Interview Tips

To ace the interview for a Brass Cutter position, it’s crucial to prepare thoroughly and demonstrate your skills and knowledge.

1. Research the Company and Role

Familiarize yourself with the company’s background, industry, and specific needs for a Brass Cutter. Understand the role’s responsibilities and expectations to tailor your answers accordingly.

2. Highlight Your Skills and Experience

Emphasize your proficiency in cutting brass using various tools and techniques. Showcase your ability to measure, mark, and cut brass accurately. Mention any experience in machine operation and maintenance, as well as knowledge of safety procedures.

3. Prepare for Technical Questions

Anticipate technical questions about cutting techniques, machine operation, and quality control. Be prepared to discuss your understanding of brass properties and how you ensure precise cuts. Practice answering questions about your experience with different cutting tools and materials.

4. Show Enthusiasm and Passion

Convey your genuine interest in the position and the industry. Demonstrate your enthusiasm for cutting and shaping brass by discussing your previous experiences or projects. Share your knowledge and passion for the craft, highlighting your dedication to delivering high-quality results.

5. Practice Your Answers

Prepare for common interview questions by practicing your answers beforehand. This will help you articulate your skills, experience, and motivation effectively. Consider using the STAR method (Situation, Task, Action, Result) to provide structured and compelling answers.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Brass Cutter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!