Are you gearing up for an interview for a Brass Molder Helper position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Brass Molder Helper and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

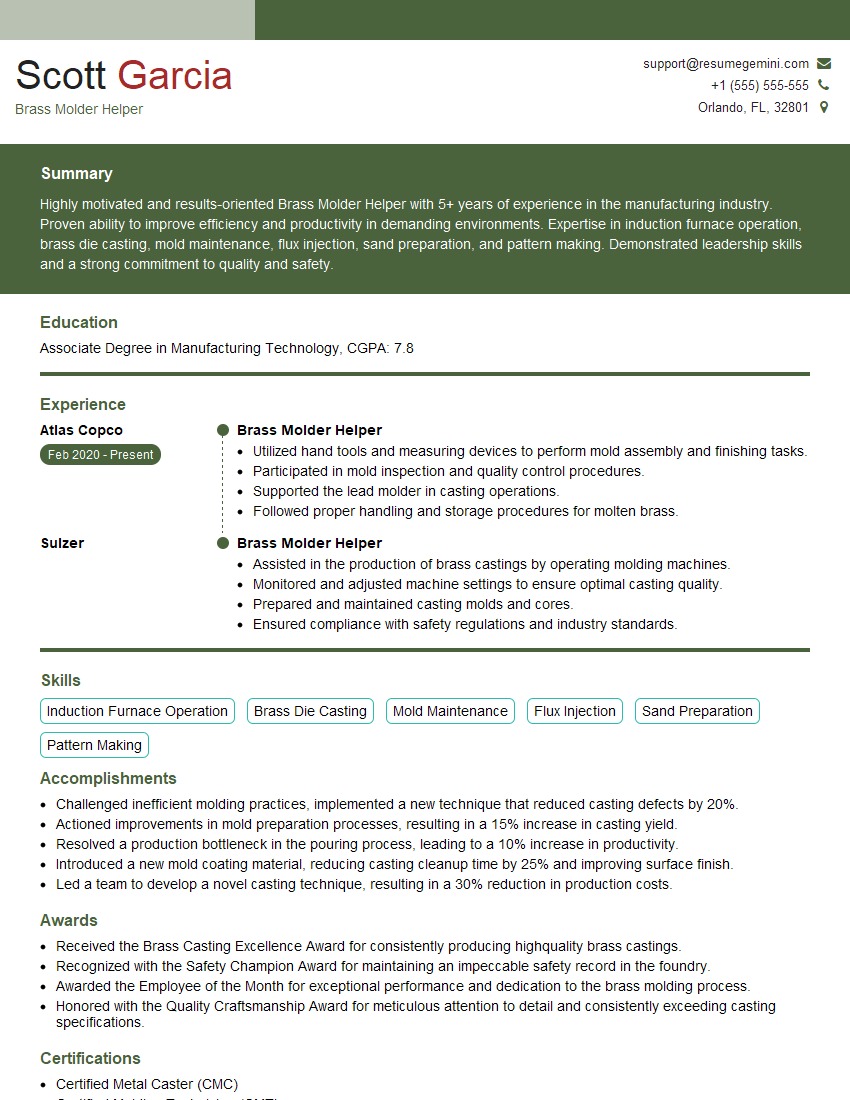

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Brass Molder Helper

1. What are the primary responsibilities of a Brass Molder Helper?

As a Brass Molder Helper, my primary responsibilities would include:

- Assisting the Brass Molder in all aspects of mold preparation and pouring

- Preparing and maintaining the molding area, tools, and equipment

- Loading and unloading materials, molds, and castings

- Monitoring the pouring process and making adjustments as needed

- Performing quality control checks on castings to ensure they meet specifications

2. What is the difference between a sand mold and a permanent mold?

- Sand mold:

- Made of sand mixed with a binder

- Can be used to create complex shapes

- Relatively inexpensive to produce

- Permanent mold:

- Made of metal or ceramic

- Can be reused multiple times

- Produces castings with higher precision and surface finish

3. What are the safety precautions that should be taken when working with molten brass?

When working with molten brass, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a face shield

- Keep the work area clean and free of debris

- Use proper lifting techniques when handling heavy objects

- Be aware of the potential for burns and take steps to avoid them

- Follow all established safety protocols and procedures

4. What are the different types of defects that can occur in brass castings?

- Shrinkage porosity: Occurs when the molten brass solidifies and contracts, creating voids in the casting

- Gas porosity: Occurs when gases become trapped in the molten brass during solidification

- Cracks: Can occur due to thermal stresses or improper cooling

- Cold shuts: Occur when two streams of molten brass do not properly fuse together

- Sand inclusions: Occur when sand from the mold becomes trapped in the casting

5. How would you troubleshoot a problem with the pouring process?

Identifying the problem:

- Check the temperature of the molten brass

- Check the flow rate of the molten brass

- Inspect the mold for any defects

- Observe the pouring process for any irregularities

Resolving the problem:

- Adjust the temperature of the molten brass as needed

- Adjust the flow rate of the molten brass as needed

- Repair or replace any defective molds

- Modify the pouring process to eliminate any irregularities

6. What are the different types of brass alloys?

- Copper-zinc alloys: These are the most common type of brass alloy and are typically composed of 60-85% copper and 15-40% zinc

- Tin brass: These alloys contain tin in addition to copper and zinc and are known for their strength and corrosion resistance

- Lead brass: These alloys contain lead in addition to copper and zinc and are used for applications where machinability is important

- Nickel brass: These alloys contain nickel in addition to copper and zinc and are known for their high strength and hardness

- Aluminum brass: These alloys contain aluminum in addition to copper and zinc and are used for applications where corrosion resistance is important

7. What are the mechanical properties of brass?

- Brass has a high strength-to-weight ratio

- It is corrosion resistant

- It is ductile and can be easily formed

- It has a relatively low melting point

- Its electrical and thermal conductivity are moderate

8. What are the different applications of brass?

- Musical instruments

- Plumbing fixtures

- Electrical components

- Marine hardware

- Decorative items

9. What is the difference between a core and a mold?

- Core: A core is a shape that is inserted into the mold to create a hollow space in the casting

- Mold: A mold is a cavity that is used to shape the molten metal into the desired form

10. What is the importance of gating system design in brass casting?

The gating system is an important part of the brass casting process because it determines how the molten brass flows into the mold.

A properly designed gating system will ensure that the molten brass flows smoothly and evenly into the mold, resulting in a high-quality casting.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Brass Molder Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Brass Molder Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Brass Molders create molds used to cast brass objects, following precisely detailed specifications.. Brass Molder Helpers assist Brass Molders in their daily tasks and responsibilities. The following is a list of key job responsibilities for a Brass Molder Helper:

1. Prepare Molds

Assist Brass Molder in preparing molds by cleaning, drying, and applying release agents

- Cleaning: Remove dirt, debris, and other contaminants from molds using brushes, compressed air, and solvents

- Drying: Ensure molds are completely dry to prevent moisture from interfering with casting process

- Applying Release Agents: Apply thin layer of release agents to mold surfaces to facilitate removal of casted objects

2. Mix and Pour Molten Brass

Assist Brass Molder in mixing and pouring molten brass into prepared molds

- Mixing: Help Brass Molder weigh and mix precise quantities of brass and alloy components

- Pouring: Assist in carefully pouring molten brass into molds to fill cavities completely and without introducing defects

3. Operate Molding Equipment

Assist Brass Molder in operating molding equipment, such as molding machines and sand rammers

- Molding Machines: Help operate machines that pack sand or other materials around patterns to create mold shape

- Sand Rammers: Help operate machines that compact sand in molds to create solid and accurate impressions

4. Inspect Castings

Assist Brass Molder in inspecting castings for defects, such as cracks, voids, or dimensional inaccuracies

- Visual Inspection: Examine castings visually for any visible flaws or imperfections

- Dimensional Inspection: Use measuring tools to verify dimensions of castings meet specifications

5. Clean and Maintain Work Area

Maintain a clean and organized work area to ensure safety and efficiency

- Cleaning: Regularly sweep, mop, and clean work area to remove debris and maintain proper hygiene

- Organizing: Keep tools, equipment, and materials organized to minimize clutter and maximize productivity

Interview Tips

Preparing for an interview can be a daunting task. Follow these interview tips and hacks to help you ace your interview for a Brass Molder Helper position:

1. Research the Company and Position

Before the interview, take the time to thoroughly research the company and the Brass Molder Helper position. This will help you understand the company’s culture, values, and the specific responsibilities of the role. You can find this information on the company’s website, social media pages, and industry publications.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. Practice answering these questions in advance so that you can deliver clear and concise responses during the interview.

3. Highlight Your Skills and Experience

In your interview, be sure to highlight your skills and experience that are relevant to the Brass Molder Helper position. This may include your experience in preparing molds, mixing and pouring molten brass, operating molding equipment, and inspecting castings. Be specific and provide examples of your work.

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a manufacturing environment. Additionally, be sure to arrive on time for your interview. Punctuality shows that you are respectful of the interviewer’s time.

5. Be Enthusiastic and Confident

Throughout the interview, be enthusiastic and confident in your abilities. Employers are looking for candidates who are passionate about their work and who are confident in their skills. Show the interviewer that you are excited about the opportunity to work as a Brass Molder Helper.

Next Step:

Now that you’re armed with the knowledge of Brass Molder Helper interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Brass Molder Helper positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini