Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Brass Molder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Brass Molder so you can tailor your answers to impress potential employers.

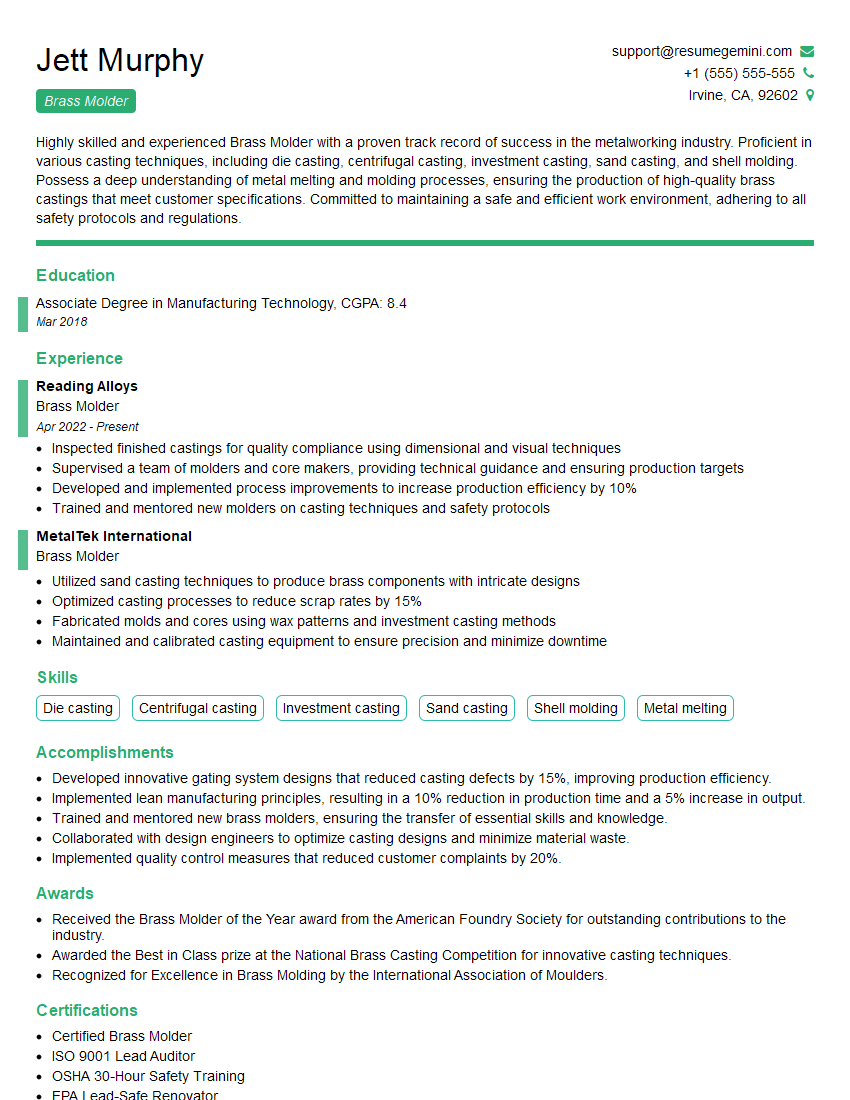

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Brass Molder

1. What are the different types of brass molding processes?

There are several types of brass molding processes, including:

- Sand casting: This is the most common type of brass molding, and it involves creating a mold out of sand and pouring molten brass into it.

- Investment casting: This process involves creating a wax pattern of the desired object, which is then coated with a ceramic material. The wax is then melted away, leaving a mold that can be filled with molten brass.

- Die casting: This process involves forcing molten brass into a metal die under high pressure. This results in a very precise and consistent product.

- Centrifugal casting: This process involves pouring molten brass into a rotating mold. This creates a centrifugal force that helps to distribute the brass evenly throughout the mold.

2. What are the different types of brass alloys?

There are many different types of brass alloys, each with its own unique properties. Some of the most common types of brass alloys include:

Copper-zinc alloys:

- These are the most common type of brass alloy, and they are composed of copper and zinc. The proportions of copper and zinc can be varied to create different properties.

Lead-free brass alloys:

- These alloys do not contain any lead, which makes them more environmentally friendly. They are often used in applications where lead contamination is a concern, such as in food and beverage equipment.

Tin-brass alloys:

- These alloys contain tin in addition to copper and zinc. Tin can improve the strength and hardness of brass, and it can also make it more resistant to corrosion.

Nickel-silver alloys:

- These alloys contain nickel in addition to copper and zinc. Nickel can improve the strength and hardness of brass, and it can also make it more resistant to corrosion and tarnish.

3. What are the factors that affect the quality of brass castings?

There are many factors that can affect the quality of brass castings, including:

- The type of brass alloy used

- The molding process

- The quality of the mold

- The casting temperature

- The cooling rate

4. What are the different defects that can occur in brass castings?

There are many different defects that can occur in brass castings, including:

- Shrinkage cavities

- Porosity

- Cracks

- Cold shuts

- Misruns

5. What are the different methods that can be used to repair brass castings?

There are many different methods that can be used to repair brass castings, including:

- Welding

- Brazing

- Soldering

- Epoxy

6. What are the safety precautions that must be taken when working with brass?

There are many safety precautions that must be taken when working with brass, including:

- Wearing appropriate personal protective equipment, such as gloves, safety glasses, and a respirator

- Ensuring that the work area is well-ventilated

- Using proper handling and storage techniques

- Being aware of the potential hazards of brass, such as lead poisoning

7. What is the difference between a brass molder and a brass caster?

A brass molder creates the mold that is used to cast brass, while a brass caster pours the molten brass into the mold. Brass molders typically work in a foundry, while brass casters can work in a variety of settings, including foundries, machine shops, and art studios.

8. What are the career opportunities for brass molders?

Brass molders can find employment in a variety of settings, including foundries, machine shops, and art studios. They can also work as independent contractors. Brass molders with experience and expertise can advance to supervisory or management positions.

9. What are the challenges of working as a brass molder?

Some of the challenges of working as a brass molder include:

- Working with heavy materials

- Exposure to heat and fumes

- Working in a noisy environment

- Meeting production deadlines

10. What are the rewards of working as a brass molder?

Some of the rewards of working as a brass molder include:

- Job security

- Good wages

- Opportunities for advancement

- The satisfaction of working with your hands

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Brass Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Brass Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Brass Molders are responsible for creating molds used in casting brass products. Their primary duties include:

1. Mold Preparation

Preparing and maintaining molds for casting brass objects.

- Constructing molds from patterns or blueprints using materials such as sand, plaster, or metal.

- Inspecting molds for defects and repairing them as necessary.

2. Metal Casting

Melting and pouring molten brass into prepared molds.

- Operating furnaces and controlling the temperature of molten brass.

- Pouring molten brass into molds and ensuring proper filling.

3. Mold Removal and Finishing

Removing castings from molds and performing finishing operations.

- Breaking apart molds to retrieve castings.

- Trimming, grinding, and polishing castings to remove imperfections.

4. Quality Control

Ensuring the quality of castings and maintaining production standards.

- Inspecting castings for defects and ensuring they meet specifications.

- Monitoring production processes and making adjustments as needed to optimize quality.

Interview Tips

Preparing for a Brass Molder interview requires research, practice, and a confident mindset. Here are some tips to help candidates ace the interview:

1. Research the Company and Position

Thoroughly research the company’s industry, products, and culture. Understand the specific role and its responsibilities.

- Visit the company website, read about their history, mission, and recent news.

- Identify the key requirements for the position and tailor your resume and answers accordingly.

2. Practice Your Answers

Prepare for common interview questions by practicing your answers out loud. Focus on highlighting your skills and experience.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide concrete examples.

- Time yourself to ensure your answers are concise and within the expected time frame.

3. Showcase Your Technical Skills

Emphasize your proficiency in brass molding techniques, including mold preparation, metal casting, and finishing processes.

- Describe specific projects you have worked on, highlighting your ability to handle different materials and tools.

- Quantify your results whenever possible, providing specific numbers or metrics to demonstrate your impact.

4. Highlight Your Quality Control Mindset

Demonstrate your attention to detail and commitment to maintaining high quality standards.

- Share examples of your quality control measures and how you have identified and resolved production issues.

- Emphasize your ability to work independently and adhere to strict specifications.

5. Be Enthusiastic and Confident

Convey your passion for brass molding and your eagerness to contribute to the company’s success.

- Show your interest in the company and the specific role.

- Come prepared with questions to ask the interviewer, demonstrating your engagement and interest in the opportunity.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Brass Molder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.