Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Brass Wind Instrument Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

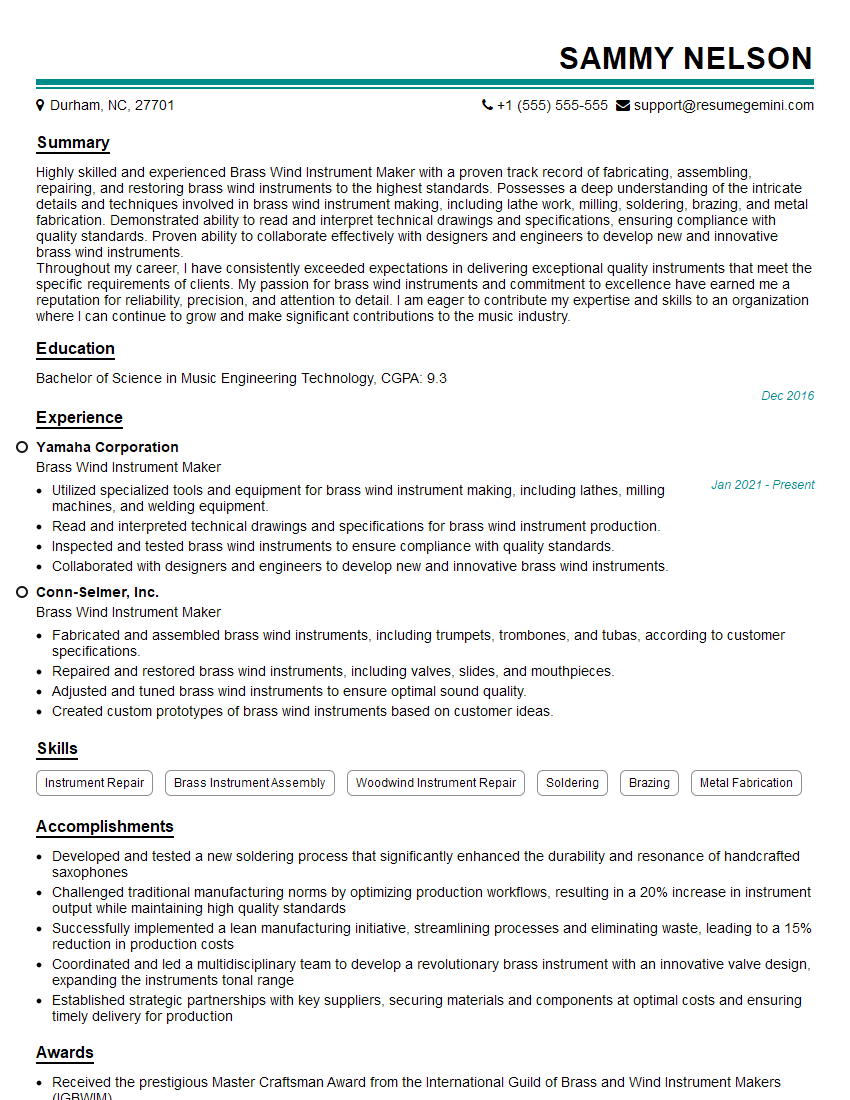

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Brass Wind Instrument Maker

1. What are the different types of brass wind instruments and what are their key characteristics?

- Trumpet: High-pitched instrument with a clear and bright sound, typically used in jazz and classical music.

- Horn: Medium-pitched instrument with a mellow and warm sound, often played in orchestras and chamber music ensembles.

- Trombone: Slide instrument with a wide range of pitches, known for its versatile sound and use in various musical genres.

- Tuba: Large, low-pitched instrument with a rich and sonorous sound, commonly used in brass bands and orchestras.

- Euphonium: Medium-sized instrument with a mellow and expressive sound, often used in brass bands and ensembles.

2. What are the common materials used to make brass wind instruments and how do they affect the instrument’s sound?

Brass Alloys

- Yellow brass: Commonly used for trumpets, horns, and trombones, providing a bright and resonant sound.

- Red brass: Found in euphoniums and tubas, known for its darker and warmer tone.

Other Materials

- Nickel silver: Used in some instruments like piccolo trumpets, offering durability and a bright sound.

- Wood: Used in the construction of didgeridoos, producing a deep and resonant sound.

3. Describe the process of creating a brass wind instrument from raw materials to a finished product.

- Material selection and preparation: Selecting the appropriate brass alloy and preparing it for forming.

- Bending and forming: Using specialized tools to bend and shape the metal into the desired instrument form.

- Soldering and brazing: Joining the different parts of the instrument using soldering or brazing techniques.

- Assembly: Fitting the various components together, including valves, tubing, and mouthpieces.

- Tuning and adjustment: Adjusting the instrument’s intonation and playability to meet specific musical requirements.

4. What are the essential tools and equipment required for a brass wind instrument maker?

- Sheet metal bender: Used for shaping brass sheets into the desired forms.

- Mallets and hammers: Essential for hammering and forming the metal.

- Soldering torch and flux: Used for joining metal parts together.

- Measuring and marking tools: To ensure accurate dimensions and alignment.

- Tuning slide: For adjusting the intonation of the instrument.

5. What are the industry standards for the dimensions and specifications of brass wind instruments?

- Adherence to pitch and intonation standards: Ensuring the instrument produces accurate musical pitches.

- Compliance with material thickness and quality requirements: Maintaining instrument durability and longevity.

- Conformance to standardized measurements and shapes: Facilitating interchangeability of parts and accessories.

- Meeting regulatory standards: Adhering to industry-specific regulations for safety and quality.

6. How do you ensure the quality of a finished brass wind instrument?

- Rigorous inspections: Thoroughly examining each instrument for defects and inaccuracies.

- Play testing: Performing musical evaluations to assess intonation, tone quality, and playability.

- Adherence to industry standards: Ensuring compliance with established specifications and quality criteria.

- Customer feedback: Gathering feedback from musicians and players to identify areas for improvement.

7. What are the common maintenance and repair tasks for brass wind instruments?

- Dent removal: Repairing dents and distortions that can affect instrument performance.

- Valve maintenance: Lubricating, cleaning, and adjusting valves to ensure smooth operation.

- Tube cleaning: Removing debris and obstructions from instrument tubing, preserving airflow and sound quality.

- Soldering repairs: Addressing cracks or breaks in the instrument’s body, ensuring structural integrity.

8. What are the emerging trends and advancements in the design and production of brass wind instruments?

- Acoustic innovations: Exploring new materials and designs to enhance sound projection and tone quality.

- Ergonomic improvements: Focusing on instrument comfort and playability for musicians.

- Digital integration: Incorporating technology into instruments for tuning assistance and educational purposes.

- Sustainable manufacturing: Prioritizing environmentally friendly practices in instrument production.

9. How do you stay updated on the latest techniques and best practices in brass wind instrument making?

- Attending industry workshops and conferences: Participating in educational events to learn from experts.

- Collaborating with other instrument makers: Exchanging knowledge and ideas with peers in the field.

- Reading technical literature: Staying informed about advancements and research in the industry.

- Experimenting with new techniques: Continuously exploring and developing innovative approaches.

10. What is your approach to customer service in your role as a brass wind instrument maker?

- Responsive communication: Promptly addressing customer inquiries and concerns.

- Tailored solutions: Providing personalized recommendations and repairs based on individual needs.

- Quality workmanship: Ensuring that every instrument meets high standards of craftsmanship.

- Post-sale support: Offering ongoing guidance and assistance to customers with their instruments.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Brass Wind Instrument Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Brass Wind Instrument Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Brass Wind Instrument Makers are skilled and experienced individuals who craft and repair brass musical instruments. Their responsibilities encompass a range of tasks that demand a deep understanding of the instruments’ materials, construction, acoustics, and playability. The following outline provides an overview of the key job responsibilities of a Brass Wind Instrument Maker:

1. Instrument Crafting

Brass Wind Instrument Makers possess exceptional craftsmanship skills and an in-depth understanding of the materials used in the construction of brass instruments, such as brass, copper, and nickel silver. They meticulously shape, solder, and assemble various components of the instruments, ensuring that each part meets the precise specifications and tolerances.

2. Instrument Repair

In addition to crafting new instruments, Brass Wind Instrument Makers are responsible for repairing and restoring existing ones. They diagnose problems, identify the source of damage or malfunction, and perform necessary repairs or replacements using specialized tools and techniques. Their expertise enables them to restore instruments to their optimal condition, extending their lifespan and preserving their playability.

3. Instrument Modifications and Customizations

Skilled Brass Wind Instrument Makers may also perform modifications and customizations to suit the specific needs of musicians. They work closely with clients to understand their requirements and make alterations to the instruments’ dimensions, materials, or other aspects to enhance their performance and playability. This specialized work demands a high level of creativity and attention to detail.

4. Quality Control and Inspection

Ensuring the quality of the instruments is a crucial aspect of the job. Brass Wind Instrument Makers meticulously inspect each instrument at various stages of production and repair, verifying that it meets the highest standards of craftsmanship and performance. Their keen eye and attention to detail guarantee that only instruments of the utmost quality are produced and delivered to musicians.

5. Research and Development

Staying abreast of the latest advancements and techniques in brass wind instrument making is essential for Brass Wind Instrument Makers. They actively engage in research and development to enhance their skills, explore new materials and methods, and contribute to the evolution of the craft. This commitment to continuous learning ensures that they remain at the forefront of their field.

Interview Preparation Tips

Preparing effectively for an interview can significantly increase your chances of success. As you prepare for your Brass Wind Instrument Maker interview, consider the following tips:

1. Research the Company and Position

Thoroughly research the company you are applying to and the specific position you are seeking. Understand their history, values, and the role’s responsibilities. This knowledge will demonstrate your interest and enthusiasm for the opportunity and enable you to tailor your answers to the interviewer’s questions.

2. Practice Your Answers

Prepare for common interview questions by rehearsing your answers in advance. Consider questions related to your experience, skills, and why you are interested in the position. Practice delivering your answers clearly and concisely, highlighting your relevant qualifications and enthusiasm for the craft.

3. Showcase Your Experience and Skills

Provide specific examples of your accomplishments and skills that align with the job responsibilities. Quantify your experience whenever possible to demonstrate the impact of your work. For instance, instead of saying “I repaired instruments,” you could say, “I successfully repaired over 500 brass wind instruments during my tenure at XYZ Music Shop.”

4. Be Professional and Enthusiastic

Dress professionally and arrive punctually for your interview. Maintain a positive and enthusiastic demeanor throughout the conversation. Show your passion for brass wind instruments and your commitment to the craft. Your enthusiasm and dedication will be evident to the interviewer and increase your chances of making a lasting impression.

5. Ask Informed Questions

Asking thoughtful questions at the end of the interview demonstrates your interest in the position and the company. Prepare questions about the company’s culture, growth opportunities, or the specific challenges and rewards of the role. Well-informed questions show that you are engaged and eager to learn more.

6. Follow Up

After the interview, send a brief thank-you note to the interviewer, reiterating your interest in the position and expressing your appreciation for their time. This follow-up demonstrates your professionalism and reinforces your application.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Brass Wind Instrument Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!