Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Brass-Wind Instruments Tube Bender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

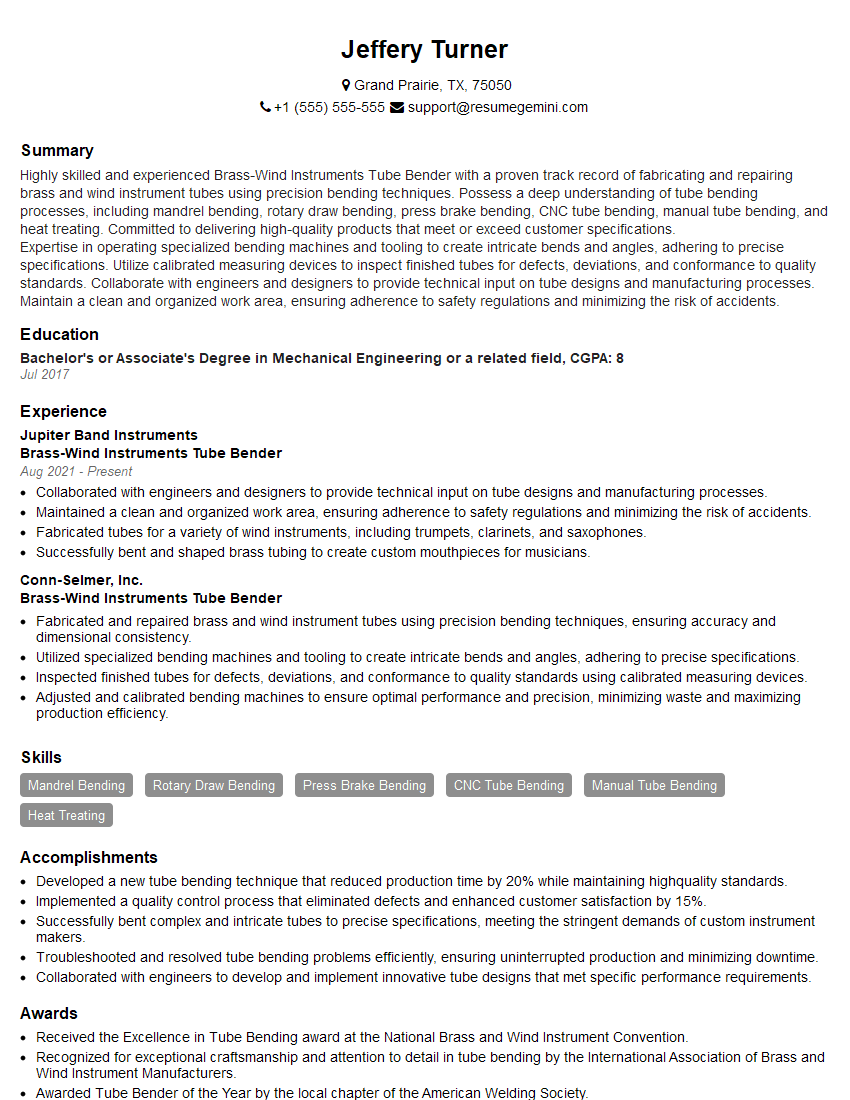

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Brass-Wind Instruments Tube Bender

1. What are the key steps involved in bending brass or wind instrument tubes?

- Annealing the tube to make it workable.

- Inserting the tube into the bender and securing it.

- Calculating the bending radius and angle.

- Bending the tube using the bender’s handle or lever.

- Checking the bend using a template or protractor.

- Trimming and finishing the bend if necessary.

2. What are the different types of tube benders used for brass and wind instruments?

Mandrel benders

- Use a mandrel inserted into the tube to prevent collapsing.

- Produce smooth, precise bends.

Rotary benders

- Use a rotating die to bend the tube.

- Can make bends with varying radii.

Compression benders

- Use a fixed die and a movable punch to bend the tube.

- Suitable for bending large-diameter tubes.

3. How do you ensure the accuracy of bends in brass or wind instrument tubes?

- Use calibrated benders and templates.

- Check bends against templates or protractors.

- Make test bends and adjust settings as needed.

- Use proper tooling and techniques to prevent deformation.

4. What are the common challenges faced when bending brass or wind instrument tubes?

- Tube collapse or flattening.

- Springback of the tube after bending.

- Cracking or tearing of the tube.

- Ovality or distortion of the tube.

5. How do you troubleshoot and resolve problems that occur during tube bending?

- Identify the root cause of the problem.

- Adjust bender settings or tooling.

- Use different bending techniques or materials.

- Contact the manufacturer for technical support.

6. What is the importance of proper tube preparation before bending?

- Ensures smooth bending without deformation.

- Reduces the risk of cracking or tearing.

- Improves the accuracy and quality of the bends.

7. How do you measure and verify the dimensions of bent tubes?

- Use calipers or micrometers to measure diameters and wall thicknesses.

- Check angles using protractors or angle gauges.

- Compare measurements to specified tolerances.

8. What is the role of annealing in tube bending?

- Softens the tube material to make it more pliable.

- Reduces the risk of cracking or tearing during bending.

- Allows for tighter bends without deformation.

9. What are the safety precautions to observe when operating a tube bender?

- Wear appropriate safety gear.

- Inspect the bender and tooling regularly.

- Follow manufacturer’s instructions for operation.

- Be aware of the hazards associated with hot tubes.

10. How do you stay up-to-date with the latest advancements in tube bending technology?

- Attend industry conferences and workshops.

- Read trade publications and articles.

- Consult with experts and manufacturers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Brass-Wind Instruments Tube Bender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Brass-Wind Instruments Tube Bender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Brass-Wind Instruments Tube Bender plays a crucial role in the production of musical instruments by expertly bending brass and wind instrument tubes to precise specifications.

1. Tube Bending Expertise

Demonstrates exceptional proficiency in bending brass and wind instrument tubes to achieve the desired angles and curvatures required for the production of high-quality musical instruments.

- Utilizes specialized bending machines to form intricate bends in tubes of varying diameters.

- Ensures accurate bending angles by employing precise measuring tools and templates.

- Repairs and maintains bending equipment to ensure optimal performance and accuracy.

2. Material Handling and Preparation

Handles and prepares brass and wind instrument tubes prior to bending.

- Inspects tubes for defects and ensures proper dimensions before bending.

- Lubricates tubes and applies heat treatments as necessary to facilitate bending.

- Prepares bending templates and fixtures to guide the bending process.

3. Quality Control

Maintains high standards of quality by inspecting finished bends.

- Conducts dimensional measurements to verify that bends meet specifications.

- Assesses the quality of bends for smoothness, absence of cracks, and overall precision.

- Identifies and corrects any defects in the bending process to ensure customer satisfaction.

4. Production Support

Collaborates with other departments to ensure efficient production.

- Coordinates with production planners to determine bending schedules and prioritize orders.

- Provides technical support to fellow team members and shares knowledge of bending techniques.

- Contributes to continuous improvement initiatives by suggesting process enhancements.

Interview Tips

Preparing for an interview for the Brass-Wind Instruments Tube Bender position requires a combination of technical knowledge, industry experience, and effective communication skills.

1. Research the Company and Role

Familiarize yourself with the company’s history, mission, and products. Research the specific role and its responsibilities to demonstrate your understanding of the position.

- Visit the company’s website and LinkedIn page.

- Read industry publications and articles to gain insights into the company’s market position.

- Prepare questions to ask the interviewer about the company and the role.

2. Highlight Your Technical Skills

Emphasize your proficiency in tube bending techniques, including bending angles, material preparation, and quality control procedures.

- Describe your experience with different types of bending machines and materials used in instrument production.

- Showcase your ability to achieve precise bends and meet specifications.

- Mention any certifications or training programs you have completed in tube bending.

3. Demonstrate Your Attention to Detail

Highlight your meticulous approach to quality control and your ability to identify and correct defects.

- Provide examples of how you have maintained high standards in your previous roles.

- Describe your quality control processes and how you ensure accuracy.

- Explain how you handle and resolve any discrepancies or errors that may arise during the bending process.

4. Showcase Your Teamwork and Communication Skills

Emphasize your ability to collaborate with others and communicate effectively within a team environment.

- Describe how you have worked effectively in previous team settings.

- Provide examples of how you have shared knowledge and supported your colleagues.

- Highlight your ability to communicate clearly and concisely, both verbally and in writing.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Brass-Wind Instruments Tube Bender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!