Are you gearing up for an interview for a Bread Molder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Bread Molder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

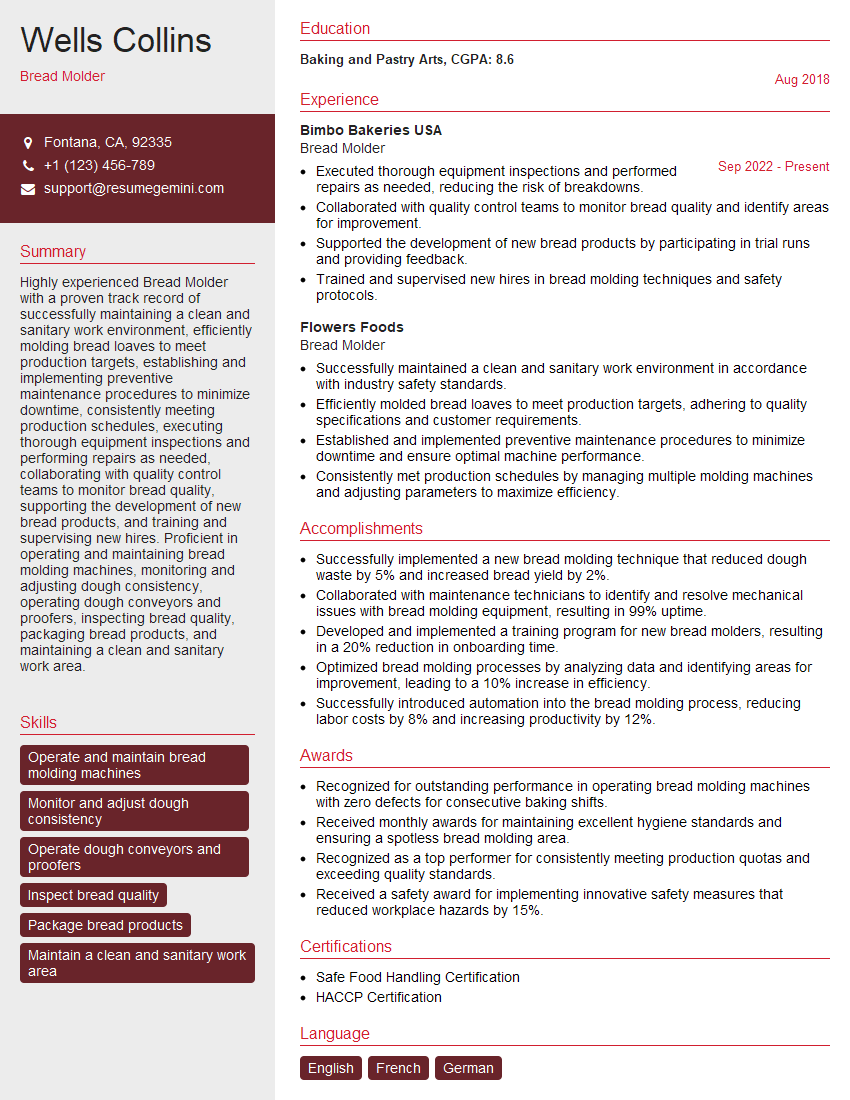

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bread Molder

1. What are the different types of bread molders available in the market?

Bread molders can be classified into two main types based on their operation:

- Mechanical Bread Molders: These molders use mechanical components to shape the dough into the desired shape. They can be manually operated or semi-automated.

- Pneumatic Bread Molders: These molders utilize compressed air to shape the dough. They offer higher automation and faster production rates compared to mechanical molders.

2. Explain the process of bread molding in detail.

Dough Preparation

- The dough is prepared by mixing flour, water, yeast, and other ingredients.

- It is then allowed to rest and rise for a specific period.

Dough Scaling

- The rested dough is divided into smaller portions of uniform weight.

- This ensures consistent loaf sizes and weights.

Dough Molding

- The scaled dough is placed into the bread molder.

- The molder shapes the dough into the desired shape, such as loaves, rolls, or baguettes.

- The molding process can involve pressing, rolling, or a combination of techniques.

Final Proofing

- After molding, the dough pieces are allowed to rest and proof again.

- This final proofing helps develop the bread’s flavor and texture.

3. Describe the different controls and settings on a bread molder and explain their functions.

- Dough Input Control: Regulates the amount of dough entering the molder.

- Molding Pressure Control: Adjusts the pressure applied to the dough during molding.

- Molding Speed Control: Sets the speed at which the dough passes through the molder.

- Panning Station Control: Positions the pans correctly to receive the molded dough.

- Safety Features: Includes emergency stop buttons, safety guards, and interlocks to ensure operator safety.

4. How do you troubleshoot common problems that may occur during bread molding?

Troubleshooting common problems in bread molding involves:

- Dough Sticking to the Molder: Causes include excessive moisture in the dough, incorrect molding pressure, or worn molder parts. Solutions involve adjusting dough hydration, cleaning the molder, or replacing worn components.

- Inconsistent Loaf Sizes: Causes include inaccurate dough scaling, variations in molding pressure, or improper pan positioning. Solutions involve calibrating the scales, ensuring uniform pressure settings, and correct pan alignment.

- Tearing of Dough: Causes include excessive molding pressure, sharp edges on the molder parts, or over-fermented dough. Solutions involve reducing molding pressure, smoothing rough edges, or adjusting proofing time.

- Mold Contamination: Causes include poor sanitation practices or accumulation of dough residues. Solutions involve regular cleaning and sanitation of the molder, as well as monitoring dough quality.

5. Explain the importance of proper maintenance and sanitation of bread molders.

- Ensures Consistent Product Quality: Clean and well-maintained molders produce uniform loaves with optimal shape and texture.

- Prevents Contamination: Regular sanitation eliminates bacteria and mold growth, reducing the risk of foodborne illnesses.

- Extends Molder Life: Proper maintenance and cleaning prevent wear and tear, increasing the molder’s lifespan.

- Maintains Hygiene: Clean and sanitary molders promote a safe and hygienic work environment.

6. Describe the different types of bread doughs that can be molded.

- Lean Doughs: Made with high-protein flour, lean doughs have a low moisture content and produce dense, chewy bread.

- Enriched Doughs: Contain added ingredients such as sugar, butter, and eggs, resulting in a richer flavor and softer texture.

- Sweet Doughs: High in sugar and fat content, sweet doughs are used for pastries and sweet breads.

- Sourdough Doughs: Made using a fermented sourdough starter, these doughs have a tangy flavor and improved shelf life.

- Whole-Wheat Doughs: Made with whole-wheat flour, these doughs are high in fiber and have a nutty flavor.

7. How do you calculate the theoretical weight of the dough pieces for different loaf sizes and shapes?

Theoretical weight calculation involves using formulas that consider the desired loaf size, shape, and the density of the dough.

- For Rectangular Loaves: Weight = Loaf Volume * Dough Density

- For Round Loaves: Weight = (4/3) * π * (Loaf Radius)^3 * Dough Density

8. Discuss the factors that influence the quality of the molded bread.

- Dough Ingredients: The type and quality of flour, yeast, and other ingredients impact the dough’s properties and the final bread quality.

- Kneading Time: Proper kneading develops gluten and improves dough strength, resulting in a better loaf structure.

- Molding Pressure: Excessive pressure can damage the dough and affect its shape and texture.

- Proofing Conditions: Adequate proofing time and temperature allow the dough to rise properly, contributing to bread volume and flavor.

- Baking Process: Oven temperature, humidity, and baking time influence the bread’s crust, color, and texture.

9. Explain how to perform routine maintenance on a bread molder.

- Daily Maintenance: Cleaning the molder parts, greasing moving components, and checking for loose screws or bolts.

- Weekly Maintenance: Inspecting belts for wear or damage, checking oil levels, and calibrating the molder’s settings.

- Monthly Maintenance: Thoroughly cleaning all parts, including the pans and scrapers, and performing a comprehensive inspection for any signs of wear or damage.

10. What safety precautions should be followed while operating a bread molder?

- Wear Appropriate Clothing: Loose clothing or jewelry should be avoided to prevent entanglement.

- Use Safety Guards: All safety guards must be in place and functional.

- Be Aware of Pinch Points: Pay attention to areas where fingers or hands could be pinched.

- Keep Hands Clear: Hands should never be placed near the molding or cutting mechanisms.

- Follow Lockout/Tagout Procedures: Lockout and tagout procedures must be followed during maintenance or repairs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bread Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bread Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bread Molders are responsible for operating and maintaining bread molding machines that shape and size dough pieces into loaves. They also perform various other tasks to ensure the efficient operation of the bakery.

1. Operate bread molding machines

Bread Molders are responsible for operating bread molding machines. This involves:

- Loading dough pieces into the molding machine

- Adjusting the molding machine to produce the desired loaf size and shape

- Monitoring the molding process to ensure that the loaves are produced to the correct specifications

2. Maintain bread molding machines

Bread Molders are also responsible for maintaining bread molding machines. This involves:

- Cleaning the molding machine on a regular basis

- Lubricating the molding machine to prevent wear and tear

- Inspecting the molding machine for any damage or problems

3. Perform other tasks

In addition to operating and maintaining bread molding machines, Bread Molders may also perform other tasks, such as:

- Preparing dough pieces for molding

- Packaging loaves of bread

- Cleaning the bakery work area

Interview Tips

To prepare for your interview, you should:

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job.

- Visit the company’s website

- Read articles about the company in the news

- Talk to people who work at the company

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method to answer interview questions

- Prepare specific examples of your skills and experience

- Practice your answers aloud

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time for your interview. This shows that you are respectful of the interviewer’s time.

- Choose clothing that is appropriate for the company culture

- Make sure your clothing is clean and pressed

- Arrive for your interview at least 15 minutes early

4. Be prepared to ask questions

At the end of your interview, the interviewer will likely ask if you have any questions. This is your opportunity to learn more about the company and the position. It is also a way to show that you are interested in the job.

- Prepare a list of questions to ask the interviewer

- Ask questions that are specific to the company and the position

- Be prepared to answer questions about your questions

Next Step:

Now that you’re armed with the knowledge of Bread Molder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Bread Molder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini