Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Breading Machine Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

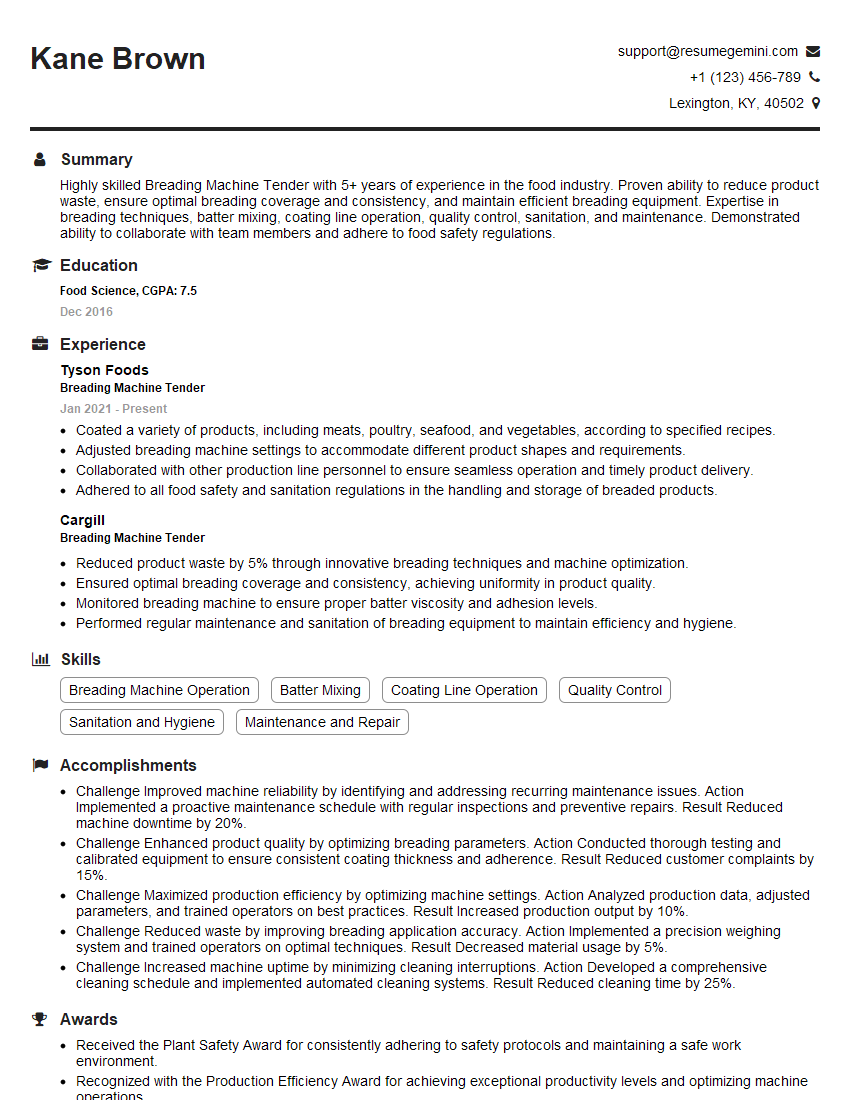

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Breading Machine Tender

1. Describe the key responsibilities of a Breading Machine Tender?

- Operate, maintain, and clean breading machines to ensure efficient production

- Monitor product quality and adjust settings to meet specifications

- Load and unload products onto conveyors

- Clean and sanitize work area and equipment to maintain a hygienic environment

2. What are some common issues you may encounter while operating a breading machine, and how would you troubleshoot them?

Troubleshooting

- Clogged or jammed conveyor: Check for obstructions, adjust tension, or clean the belt

- Uneven breading: Inspect the breading applicator, adjust settings, or check the product feed rate

- Product sticking to the belt: Adjust the belt speed, check for moisture levels, or apply an anti-stick agent

Preventive Maintenance

- Clean and lubricate the machine regularly

- Inspect belts, bearings, and other components for signs of wear

- Calibrate sensors and adjust settings to ensure optimal performance

3. How do you ensure that the breading meets the desired thickness and adhesion?

- Adjust the breading applicator settings (e.g., speed, volume, angle)

- Monitor product feed rate and conveyor speed to control dwell time

- Use breading mixes with appropriate viscosity and adhesion properties

- Check the product temperature and humidity levels

4. How would you handle a situation where the breading machine malfunctions during production?

- Stop the machine immediately and identify the problem

- Inform the supervisor and maintenance team

- Take any necessary safety precautions (e.g., lockout/tagout)

- Assist in troubleshooting and repair if possible

5. What types of sanitation and hygiene practices are important in a breading operation?

- Clean and sanitize the machine regularly

- Wear appropriate protective gear (e.g., gloves, hairnets)

- Wash hands thoroughly and prevent cross-contamination

- Monitor product temperature and humidity to prevent spoilage

- Adhere to established sanitation protocols

6. How do you ensure that the breading operation is running efficiently and producing consistent results?

- Monitor machine performance and adjust settings as needed

- Conduct regular maintenance and calibration

- Use standardized recipes and procedures

- Train operators on proper techniques and troubleshootings

7. What is the role of a breading machine in the food production process?

- Applies a uniform layer of breading to food products

- Improves product appearance, texture, and flavor

- Protects the product from moisture loss and oxidation

- Enhances the nutritional value of the product

8. How do you calibrate a breading machine to ensure accurate performance?

- Use standardized weights or volumes to measure the amount of breading applied

- Adjust settings (e.g., belt speed, applicator angle) to achieve the desired results

- Monitor product quality and make adjustments as needed

9. What is the importance of using the correct viscosity of breading mix?

- Ensures proper adhesion to the product

- Prevents clumping or excessive runoff

- Optimizes breading thickness and texture

- Minimizes waste and reduces production costs

10. How do you maintain a clean and organized breading station?

- Regularly sweep or vacuum the area

- Clean and sanitize surfaces and equipment

- Dispose of waste properly

- Store breading mix and other ingredients in designated areas

- Inspect and maintain equipment to prevent spills or leaks

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Breading Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Breading Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Breading Machine Tenders are essential to the success of food processing operations by ensuring the smooth and efficient operation of breading machines. They play a crucial role in producing high-quality breaded food products, such as chicken nuggets, fish sticks, or onion rings, by monitoring the breading process, maintaining equipment, and ensuring food safety standards.

1. Monitor and Adjust Breading Machine Operation

Tenders closely monitor the breading machine’s performance, making necessary adjustments to ensure optimal breading application and product quality. They observe the flow of product through the machine, checking for any abnormalities or blockages, and adjust settings such as conveyor speed, breader gap, and batter consistency to achieve the desired coating thickness and adhesion.

2. Maintain and Clean Equipment

Regular maintenance is essential for the smooth operation of the breading machine. Tenders perform daily cleaning tasks, such as removing excess batter and crumbs from the machine and its components. They also conduct regular inspections and perform minor repairs to ensure the machine is in good working condition, preventing breakdowns and downtime.

3. Ensure Food Safety and Quality Control

Tenders play a vital role in maintaining food safety and quality standards in the breading process. They adhere to established food safety protocols, including proper handling of ingredients, monitoring product temperatures, and implementing sanitation procedures to prevent contamination. They also perform regular quality checks on the breaded products, ensuring they meet specifications for appearance, coating uniformity, and other quality attributes.

4. Collaborate with Other Team Members

Tenders work closely with other members of the production team, including machine operators, quality control personnel, and maintenance technicians. They communicate effectively to ensure smooth coordination and resolve any issues promptly. Collaboration is essential for maintaining a safe and efficient work environment and achieving production targets.

Interview Tips

Preparing thoroughly for your interview as a Breading Machine Tender can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Role

Before the interview, take the time to research the company and the specific role you are applying for. Understand the company’s values, mission, and industry standing. Learn about the breading machine tender’s responsibilities, skills, and qualifications to tailor your answers to the interviewer’s expectations.

2. Practice Common Interview Questions

Anticipate common interview questions and prepare thoughtful responses. Practice answering questions about your experience operating breading machines, your knowledge of food safety regulations, and your ability to work in a fast-paced production environment. Use the STAR method (Situation, Task, Action, Result) to structure your answers, providing specific examples of your skills and accomplishments.

3. Emphasize Your Attention to Detail

Breading Machine Tenders must have a keen eye for detail to ensure the accuracy and quality of the breading process. Highlight your ability to monitor multiple aspects of the operation simultaneously, such as product flow, batter consistency, and machine settings. Share examples of how you have identified and resolved issues promptly, preventing downtime and maintaining product quality.

4. Demonstrate Your Food Safety Knowledge

Food safety is paramount in the food processing industry. Emphasize your understanding of food safety principles and practices. Explain how you have implemented sanitation procedures, monitored product temperatures, and maintained a clean and hygienic work environment. Share examples of how you have contributed to maintaining food safety standards in previous roles.

5. Highlight Your Teamwork and Communication Skills

Breading Machine Tenders often work as part of a team in a fast-paced production environment. Highlight your ability to communicate effectively, collaborate with others, and resolve issues efficiently. Provide examples of how you have worked effectively in teams, contributed to problem-solving, and maintained a positive work environment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Breading Machine Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!