Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Breaker Up Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Breaker Up Machine Operator so you can tailor your answers to impress potential employers.

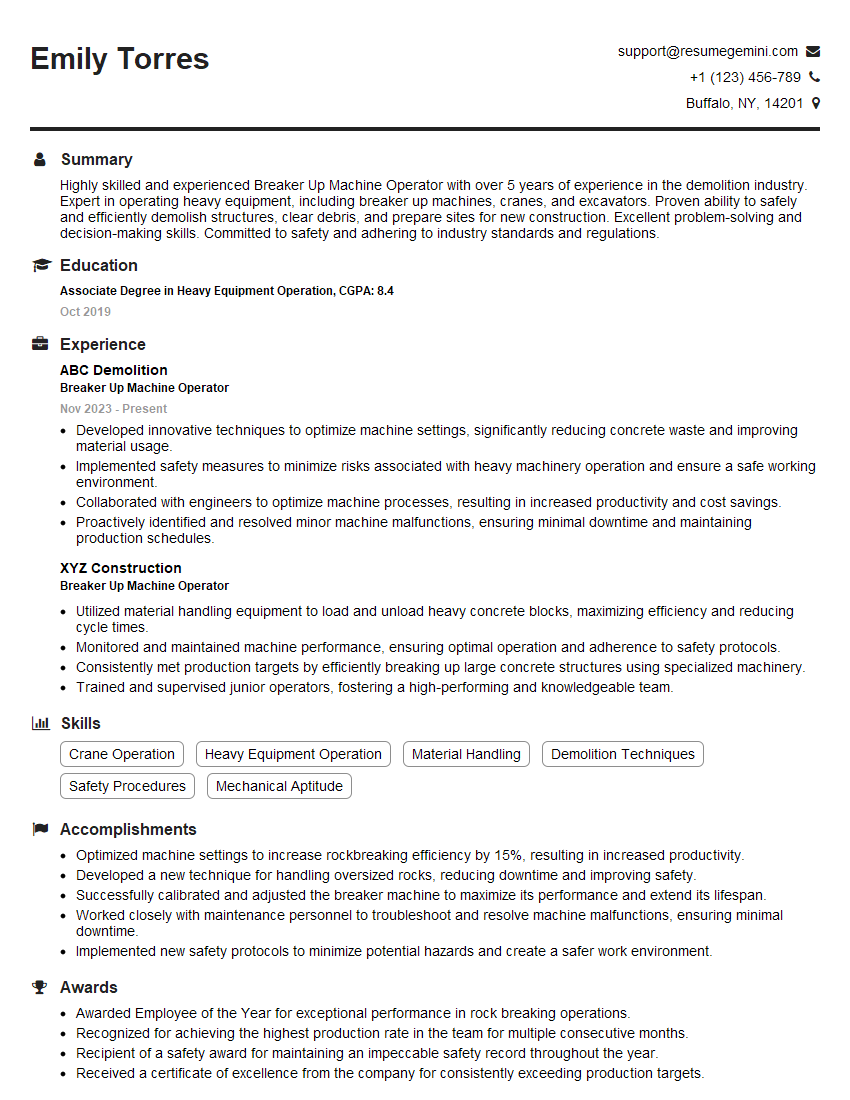

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Breaker Up Machine Operator

1. What are the different types of breaker up machines? Explain their working principle.

There are two main types of breaker up machines: hydraulic and mechanical.

- Hydraulic breaker up machines use a hydraulic cylinder to power the breaking head. The hydraulic fluid is pressurized by a pump, which drives the piston in the cylinder. The piston, in turn, drives the breaking head up and down, which breaks up the material.

- Mechanical breaker up machines use a motor to power the breaking head. The motor drives a series of gears, which in turn drive the breaking head up and down. Mechanical breaker up machines are typically smaller and lighter than hydraulic breaker up machines, and they are often used in applications where portability is important.

2. How do you maintain a breaker up machine?

Daily Maintenance

- Check the hydraulic fluid level and add fluid as needed.

- Inspect the hydraulic hoses and fittings for leaks.

- Lubricate the moving parts of the machine.

- Clean the machine of any debris.

Weekly Maintenance

- Change the hydraulic fluid.

- Clean the hydraulic filter.

- Inspect the breaking head for wear and tear.

- Tighten any loose bolts or nuts.

Monthly Maintenance

- Inspect the electrical system for any loose wires or connections.

- Test the safety features of the machine.

- Have the machine serviced by a qualified technician.

3. What are the safety precautions that you should take when operating a breaker up machine?

- Always wear appropriate safety gear, including safety glasses, earplugs, and gloves.

- Be aware of your surroundings and keep others away from the work area.

- Never operate a breaker up machine while under the influence of drugs or alcohol.

- Follow all manufacturer’s instructions for the safe operation of the machine.

4. How do you troubleshoot a breaker up machine?

- The machine is not starting:

- Check the power supply.

- Check the hydraulic fluid level.

- Check the hydraulic hoses and fittings for leaks.

- Check the motor.

- The machine is not breaking up the material:

- Check the breaking head for wear and tear.

- Check the hydraulic pressure.

- Check the material that is being broken up.

- The machine is making a strange noise:

- Check the hydraulic fluid level.

- Check the hydraulic hoses and fittings for leaks.

- Check the motor.

- Check the breaking head.

5. What are the different types of materials that can be broken up using a breaker up machine?

- Concrete

- Asphalt

- Brick

- Stone

- Metal

- Wood

6. What are the advantages of using a breaker up machine?

- Speed: Breaker up machines can break up materials quickly and efficiently.

- Power: Breaker up machines are powerful enough to break up even the toughest materials.

- Versatility: Breaker up machines can be used to break up a variety of different materials.

- Portability: Breaker up machines are relatively portable, making them easy to use in different locations.

- Safety: Breaker up machines are equipped with a variety of safety features, making them safe to operate.

7. What are the disadvantages of using a breaker up machine?

- Noise: Breaker up machines can be noisy, which can be a nuisance to workers and nearby residents.

- Vibration: Breaker up machines can create vibrations, which can be uncomfortable for workers and can damage nearby structures.

- Dust: Breaker up machines can create dust, which can be harmful to workers and can interfere with other work activities.

- Cost: Breaker up machines can be expensive to purchase and maintain.

- Safety: Breaker up machines can be dangerous to operate, so it is important to follow all safety precautions.

8. What are the applications of breaker up machines?

- Demolition

- Construction

- Mining

- Recycling

- Landscaping

9. What are the factors to consider when choosing a breaker up machine?

- The type of material that you will be breaking up – Different types of breaker up machines are designed to break up different types of materials. It is important to choose a machine that is designed for the specific material that you will be breaking up.

- The size of the material that you will be breaking up – Breaker up machines come in a variety of sizes. It is important to choose a machine that is large enough to break up the size of material that you will be working with.

- The power of the machine – Breaker up machines come with a variety of power ratings. It is important to choose a machine that has enough power to break up the material that you will be working with.

- The portability of the machine – Breaker up machines come in a variety of portable sizes. It is important to choose a machine that is portable enough for your specific needs.

- The safety features of the machine – Breaker up machines come with a variety of safety features. It is important to choose a machine that has the safety features that you need.

10. What is the average lifespan of a breaker up machine?

The average lifespan of a breaker up machine is 5 to 10 years. However, the lifespan of the machine can be extended by following the manufacturer’s maintenance instructions and by using the machine in a safe and responsible manner.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Breaker Up Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Breaker Up Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Breaker Up Machine Operators are responsible for the operation of breaker up machines, which are used to break up large pieces of material into smaller pieces. They also perform other related tasks, such as:

1. Machine Operation

They monitor the machine’s operation and make sure that it is functioning properly. They also adjust the machine’s settings according to the material being processed.

- Setting up the breaker up machine

- Monitoring the machine’s performance

- Making necessary adjustments to the machine

2. Material Handling

Breaker Up Machine Operators load and unload the machine with materials. They also remove any debris or waste from the machine.

- Loading and unloading the breaker up machine with materials

- Removing debris and waste from the machine

- Ensuring that the work area is clean and safe

3. Quality Control

Breaker Up Machine Operators inspect the finished product to ensure that it meets quality standards. They also make sure that the machine is producing the correct size and shape of material.

- Inspecting the finished product

- Ensuring that the product meets quality standards

- Making sure that the machine is producing the correct size and shape of material

4. Maintenance

Breaker Up Machine Operators perform basic maintenance on the machine, such as cleaning, lubrication, and repairs. They also report any major problems to their supervisors.

- Cleaning and lubricating the machine

- Performing minor repairs

- Reporting any major problems to supervisors

Interview Tips

To ace the interview for a Breaker Up Machine Operator position, it is important to be prepared. Here are some tips:

1. Research the Company and the Position

Research the company’s website and social media pages to learn more about its culture, values, and products. Also, review the job description thoroughly to understand the specific responsibilities of the position.

- Visit the company’s website

- Read the job description carefully

- Check out the company’s social media pages

2. Practice Your Answers to Common Interview Questions

There are some common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Practice answering these questions in advance so that you can deliver your responses confidently and concisely.

- Write down your answers to common interview questions

- Practice saying your answers out loud

- Get feedback from a friend or family member

3. Highlight Your Skills and Experience

In your interview, be sure to highlight the skills and experience that you have that are relevant to the position. For example, if you have experience operating heavy machinery, be sure to mention this in your interview. Quantify your experience to make your skills and experience stand out.

- List your skills and experience on your resume

- Talk about your skills and experience in your interview

- Quantify your experience whenever possible

4. Ask Questions

Asking questions at the end of the interview shows that you are interested in the position and the company. It also gives you a chance to learn more about the company and the position. Some good questions to ask include “What are the biggest challenges facing the company right now?” and “What is the company’s culture like?”.

- Prepare questions to ask the interviewer

- Ask questions that show your interest in the position and the company

- Listen carefully to the interviewer’s answers

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Breaker Up Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.