Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Brewer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

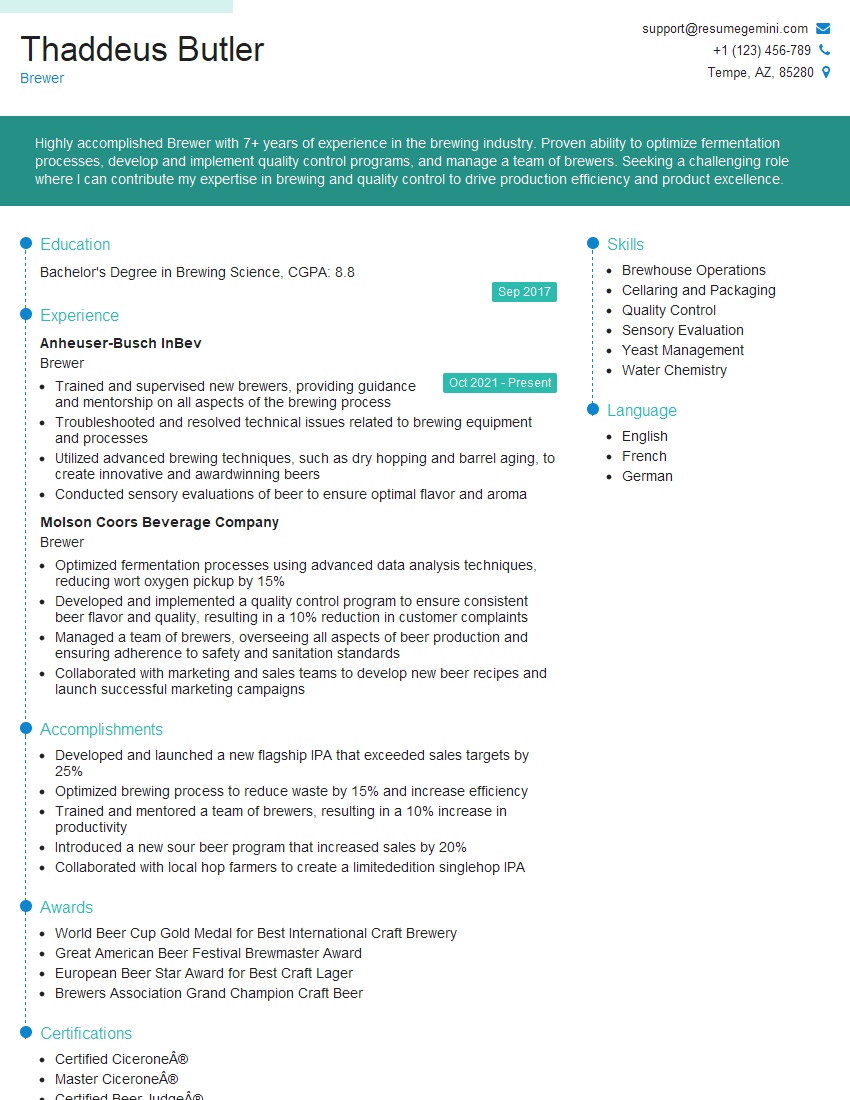

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Brewer

1. What are the key factors to consider when designing a brewery’s water treatment system?

- Water source quality and composition

- Target beer style and flavor profile

- Brewhouse operating parameters

- Regulations and industry standards

- Cost and space constraints

2. Describe the different types of fermentation vessels and discuss their advantages and disadvantages.

Open vs. Closed Fermenters

- Open fermenters: Advantages – easier to clean and monitor, less risk of infection; Disadvantages – greater potential for oxidation, higher evaporation rates

- Closed fermenters: Advantages – reduced oxidation, better temperature control; Disadvantages – more difficult to clean, higher risk of infection

Horizontal vs. Vertical Fermenters

- Horizontal fermenters: Advantages – better utilization of space, easier to access for cleaning; Disadvantages – potential for stratification

- Vertical fermenters: Advantages – better temperature control, less risk of stratification; Disadvantages – more difficult to access for cleaning

3. How do you approach troubleshooting common brewing problems, such as off-flavors or contamination?

- Identify the problem and its potential causes based on sensory evaluation and process data

- Review brewing procedures and raw materials to identify potential sources of the problem

- Conduct laboratory tests, such as microbiological analysis, to confirm or rule out specific causes

- implement corrective measures based on the analysis and testing results

- Monitor the situation and make adjustments as necessary until the problem is resolved

4. How do you ensure quality control throughout the brewing process?

- Establishing and following standardized operating procedures (SOPs)

- Regular monitoring and testing of raw materials, in-process products, and finished beer

- Implementing a quality management system, such as ISO 9001

- Providing training and resources to ensure that all employees understand and follow quality standards

- Conducting regular audits and reviews to identify areas for improvement

5. What are the key considerations when selecting and managing yeast for brewing?

- Yeast strain selection: Compatibility with beer style, fermentation temperature, and desired flavor profile

- Yeast preparation: Proper rehydration, starter culture preparation, and pitching rate

- Fermentation management: Temperature control, nutrient addition, and monitoring of fermentation progress

- Yeast handling: Proper storage, handling, and repitching techniques to maintain yeast viability and quality

- Yeast management strategies: Rotation schedules, strain maintenance, and contamination prevention

6. How do you optimize wort production to achieve desired beer characteristics?

- Grain selection and milling: Choice of malts and adjuncts, proper grain preparation

- Mashing process: Temperature profile, pH control, enzyme activity

- Lautering: Sparging techniques, runoff rate, bed depth

- Wort boiling: Timing, temperature, hop additions

- Cooling and aeration: Chilling rate, oxygen levels for yeast growth

7. What are the principles and best practices of beer packaging, including sanitation, filling, and labeling?

- Sanitation: Cleaning and disinfecting packaging equipment, bottles, and cans

- Filling: Proper carbonation levels, accurate volume, minimizing foam and oxygen pickup

- Labeling: Compliance with regulations, accurate information, eye-catching design

- Packaging formats: Considerations for bottles, cans, kegs, and other packaging options

- Quality control: Monitoring and testing to ensure package integrity and beer quality

8. Describe the different types of filtration systems used in brewing and their respective advantages and disadvantages.

-

Pressure leaf filters

- Advantages: High efficiency, fast filtration rates

- Disadvantages: Require large amounts of filter media, can be expensive to operate

-

Crossflow filters

- Advantages: Gentle on beer, continuous operation

- Disadvantages: Lower filtration rates, higher energy consumption

-

Centrifuges

- Advantages: Compact design, high capacity

- Disadvantages: Can be less efficient, may produce some sediment

9. How do you manage and optimize energy consumption in a brewery?

- Energy audits and monitoring

- Equipment upgrades and retrofits

- Process optimization and automation

- Renewable energy sources (e.g., solar, wind)

- Employee training and awareness

10. Describe your experience with brewing software and automation systems.

- Brewery management software (e.g., BreweryDB, Brewmaster)

- Automated control systems (e.g., PLCs, SCADA)

- Data analytics and reporting tools

- Experience with implementing and troubleshooting automation systems

- Understanding of industry best practices and technological advancements

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Brewer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Brewer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Brewers are responsible for the entire brewing process, from sourcing ingredients to packaging and distributing the finished product. They oversee every step of production, ensuring that the beer meets the desired quality standards. Key job responsibilities include:

1. Recipe Development and Quality Control

Brewers develop and refine recipes for new beers, ensuring that they meet the desired flavor profile. They also conduct quality control tests throughout the brewing process to ensure that the beer meets the desired specifications.

- Develop new beer recipes and refine existing ones.

- Conduct quality control tests on raw materials, in-process products, and finished products.

- Troubleshoot production problems and implement corrective actions.

2. Brewing Process Management

Brewers manage the brewing process from start to finish, ensuring that the beer is produced efficiently and to the desired quality standards. They oversee all aspects of the brewing process, including:

- Mashing: Converting the starches in the grain into sugars

- Lautering: Separating the wort (sugar water) from the grain

- Boiling: Adding hops to the wort to add flavor and bitterness

- Fermentation: Converting the wort into beer by adding yeast

- Conditioning: Allowing the beer to mature and develop its flavor

3. Equipment Maintenance and Sanitation

Brewers are responsible for maintaining and cleaning all of the equipment used in the brewing process. This includes cleaning and sanitizing tanks, kettles, pumps, and other equipment. They also perform regular maintenance on equipment to ensure that it is operating properly.

- Clean and sanitize brewing equipment.

- Perform regular maintenance on brewing equipment.

- Calibrate and maintain instruments and controls.

4. Production Planning and Scheduling

Brewers plan and schedule the production process to ensure that the beer is produced efficiently and on time. They work with other departments to coordinate production activities and ensure that the brewery is operating smoothly.

- Plan and schedule production activities.

- Coordinate with other departments to ensure smooth operation.

- Monitor production progress and make adjustments as needed.

Interview Tips

Preparing for a Brewer interview can be daunting, but with the right approach, you can increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Brewery and the Industry

Before the interview, take some time to research the brewery you’re applying to and the brewing industry as a whole. This will help you understand the company’s culture and values, as well as the current trends in the industry. You can find information on the brewery’s website, social media pages, and industry publications.

- Visit the brewery’s website and social media pages.

- Read industry publications and articles.

- Talk to other brewers or industry professionals.

2. Highlight Your Experience and Skills

During the interview, be sure to highlight your experience and skills that are relevant to the job. This includes your brewing experience, as well as any other skills that would be valuable to the brewery, such as quality control, production planning, or equipment maintenance. You can also mention any certifications or training that you have completed.

- Quantify your accomplishments whenever possible.

- Use specific examples to illustrate your skills.

- Be prepared to discuss your experience in detail.

3. Be Enthusiastic and Passionate

Brewing is a passion for many people, so it’s important to show the interviewer that you’re enthusiastic about the job. Talk about your passion for brewing and why you’re interested in working for the brewery. You can also share your favorite beers and what you like about them.

- Be yourself and let your personality shine through.

- Show the interviewer that you’re excited about the opportunity.

- Be prepared to talk about your favorite beers and why.

4. Ask Questions

At the end of the interview, be sure to ask the interviewer questions about the job and the brewery. This shows that you’re interested in the position and that you’re eager to learn more. You can ask about the brewery’s production process, the company’s culture, or the interviewer’s own experience in the industry.

- Prepare questions in advance so that you don’t forget.

- Ask questions that are relevant to the job and the brewery.

- Be prepared to follow up on your questions after the interview.

5. Follow Up

After the interview, be sure to send a thank-you note to the interviewer. This is a great way to reiterate your interest in the job and to thank the interviewer for their time. You can also use the thank-you note to clarify any points that you discussed during the interview.

- Send a thank-you note within 24 hours of the interview.

- Reiterate your interest in the job.

- Thank the interviewer for their time.

- Clarify any points that you discussed during the interview.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Brewer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Brewer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.