Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Brewmaster position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

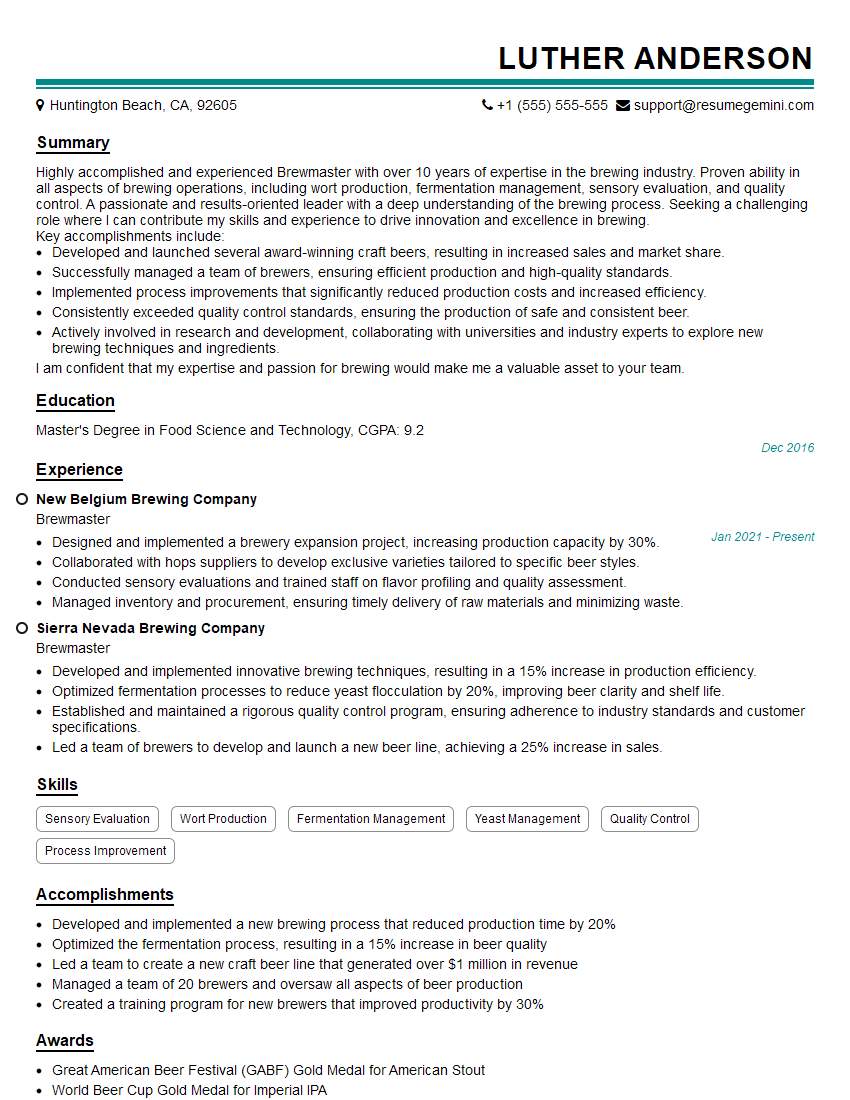

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Brewmaster

1. What are the key stages involved in the brewing process?

The key stages involved in the brewing process are:

- Malting: Steeping, germination, and kilning of barley to produce malt.

- Mashing: Mixing malt with hot water to convert starches into sugars.

- Lautering: Separating the sweet wort from the spent grain.

- Boiling: Wort is boiled with hops to impart bitterness, flavor, and aroma.

- Cooling: Wort is cooled to allow yeast to ferment the sugars.

- Fermentation: Yeast converts sugars into alcohol and carbon dioxide.

- Conditioning: Beer is aged to develop flavors and mature.

2. Explain the role of different malt types in beer production.

Malting process:

- Steeping: Barley is soaked in water to rehydrate the kernels.

- Germination: Barley is allowed to germinate, which activates enzymes that convert starches into sugars.

- Kilning: Germination is stopped by heating the barley, which develops flavors and aromas.

Role of different malt types:

- Pale malt: Used for light-colored beers, provides a light, malty flavor.

- Caramel malt: Adds sweetness and reddish-brown color.

- Crystal malt: Roasted malt, imparts sweetness and a dark brown color.

- Chocolate malt: Roasted malt, adds chocolatey flavors and black color.

- Black patent malt: Highly roasted malt, imparts a roasted bitterness and black color.

3. Describe the impact of water chemistry on beer flavor.

Water chemistry plays a crucial role in beer flavor by influencing:

- pH: Affects enzyme activity, hop utilization, and microbial stability.

- Hardness: Calcium and magnesium content influences mash stability, hop extraction, and flavor profile.

- Alkalinity: Bicarbonate and carbonate content buffers pH and affects extract yield.

- Chloride: Enhances hop bitterness and fullness of flavor.

- Sulfate: Balances hop bitterness and provides a crisp, dry finish.

4. Explain the principles of hop utilization and how it affects beer flavor.

Hop utilization refers to the extraction of flavors and aromas from hops during the brewing process. It impacts beer flavor by:

- Bittering: Boiling hops early in the process imparts alpha acids that contribute bitterness.

- Aroma: Adding hops late in the boil or during fermentation releases essential oils that provide aroma.

- Dry hopping: Adding hops after fermentation enhances aroma and flavor.

- Hop variety: Different hop varieties contribute unique flavor and aroma profiles.

- Hop dosage: The amount of hops used influences the intensity of bitterness and aroma.

5. Describe the role of fermentation in beer production.

Fermentation is a crucial stage where yeast converts sugars into alcohol and carbon dioxide, giving beer its characteristic flavors and aromas. Factors influencing fermentation include:

- Yeast strain: Different yeast strains produce unique flavor profiles.

- Fermentation temperature: Temperature affects yeast activity and flavor development.

- Fermentation time: The duration of fermentation determines the extent of sugar conversion and flavor maturation.

- Oxygenation: Oxygen levels can impact yeast health and flavor production.

- Secondary fermentation: Some beers undergo a second fermentation to develop specific flavors.

6. Explain the importance of quality control in brewing.

Quality control ensures the production of consistent, high-quality beer by:

- Raw material testing: Inspecting malt, hops, and water for quality and consistency.

- Process monitoring: Checking fermentation, temperature, and other process parameters to ensure optimal conditions.

- Sensory evaluation: Regular tasting and analysis of beer to assess flavor, aroma, and appearance.

- Microbiological testing: Monitoring for harmful microorganisms to ensure beer safety.

- Equipment maintenance: Regularly inspecting and cleaning equipment to prevent contamination.

7. Describe the principles of beer packaging and how it affects beer quality.

Beer packaging involves sealing and storing beer to maintain its quality. Factors to consider include:

- Container type: Glass bottles, aluminum cans, or kegs have different permeability and storage requirements.

- Package volume: The amount of beer in a package influences headspace and oxygen exposure.

- Sealing method: Capping or crowning bottles, seaming cans, or tapping kegs must ensure airtight seals.

- Temperature control: Proper storage temperature is crucial to prevent flavor and aroma loss.

- Oxygen management: Oxygen can oxidize beer, so measures like nitrogen flushing are used to minimize its presence.

8. Explain the role of a Brewmaster in managing a brewery operation.

A Brewmaster plays a pivotal role in managing brewery operations by:

- Quality control: Ensuring consistent beer production and meeting quality standards.

- Recipe development: Creating and refining beer recipes to meet market demands.

- Process optimization: Improving brewing efficiency and reducing costs.

- Equipment maintenance: Coordinating maintenance and repairs to keep equipment running smoothly.

- Team management: Leading and motivating a team of brewers.

- Customer relations: Interacting with customers, receiving feedback, and addressing complaints.

9. Describe the challenges and rewards of being a Brewmaster.

Challenges:

- Balancing creativity with technical proficiency.

- Managing a highly regulated industry.

- Meeting production demands while maintaining quality.

- Staying abreast of industry trends and technologies.

- Working long hours, especially during peak seasons.

Rewards:

- Creating a tangible product that people enjoy.

- Witnessing the transformation of raw ingredients into a beloved beverage.

- Working in a collaborative and creative environment.

- Receiving recognition for exceptional beers.

- Making a positive impact on the local community.

10. How do you stay updated with advancements in brewing science and technology?

I stay updated with advancements in brewing science and technology through:

- Attending industry conferences and workshops.

- Reading technical journals and research papers.

- Networking with other brewers and professionals.

- Visiting pilot breweries and research facilities.

- Working with suppliers who provide information on new products and technologies.

- Conducting my own experiments and trials.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Brewmaster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Brewmaster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Brewmasters play a vital role in the beer-making process, taking care of every aspect from start to finish. Their knowledge and expertise ensure consistent, high-quality beer production, meeting the demands of consumers and industry standards.

1. Brewing Process Oversight

Brewmasters oversee the brewing process from start to finish, ensuring adherence to recipes and maintaining brewing schedules. This includes:

- Selecting and preparing raw materials (malt, hops, yeast, water)

- Mashing, lautering, boiling, and cooling wort

- Fermentation and conditioning of beer

- Monitoring and controlling fermentation parameters (temperature, pH, specific gravity)

2. Quality Control and Assurance

Brewmasters are responsible for ensuring the quality and consistency of the final product. This involves:

- Sensory evaluation of beer (taste, aroma, color, clarity)

- Microbiological and chemical analysis

- Implementing quality control measures throughout the brewing process

- Troubleshooting and resolving production issues

3. Equipment Maintenance and Management

Brewmasters ensure the proper operation and maintenance of brewing equipment, including:

- Brewhouse, fermentation tanks, conditioning vessels

- Pumps, valves, pipelines, and other equipment

- Calibration and maintenance of instruments

- Adherence to safety protocols and regulations

4. Research and Development

Brewmasters may also participate in research and development activities, experimenting with new brewing techniques, ingredients, and recipes. This can include:

- Developing new beer styles or flavors

- Improving brewing efficiency and sustainability

- Collaborating with other professionals in the industry

Interview Tips

Preparing for a Brewmaster interview requires a combination of technical knowledge and a showcase of your passion for the craft. Here are a few tips to help you ace the interview:

1. Research the Company and Industry

Demonstrate your interest in the company and the brewing industry by researching their products, history, and recent developments. Understanding the company’s values and goals will help you align your skills and experience with their needs.

2. Highlight Your Technical Expertise

As a Brewmaster, you need a deep understanding of brewing science and production processes. Be prepared to discuss your knowledge of fermentation, quality control, equipment maintenance, and troubleshooting. Bring examples from your past experience to demonstrate your technical abilities.

3. Showcase Your Leadership Skills

Brewmasters often lead teams of brewers and oversee production operations. Highlight your leadership qualities, such as communication, delegation, and conflict resolution. Provide examples of how you have effectively managed and motivated teams in the past.

4. Emphasize Your Passion for Beer

Brewmasters are passionate about beer and the brewing process. Share your knowledge of beer styles, flavors, and brewing techniques. Discuss your personal experiences with beer and how it has influenced your career path.

5. Prepare Questions

Asking thoughtful questions not only shows your engagement but also provides an opportunity to learn more about the company and the role. Prepare a few well-researched questions that demonstrate your interest and understanding of the industry.

By following these tips and showcasing your knowledge, passion, and leadership skills, you can increase your chances of success in a Brewmaster interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Brewmaster interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.