Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Brick Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

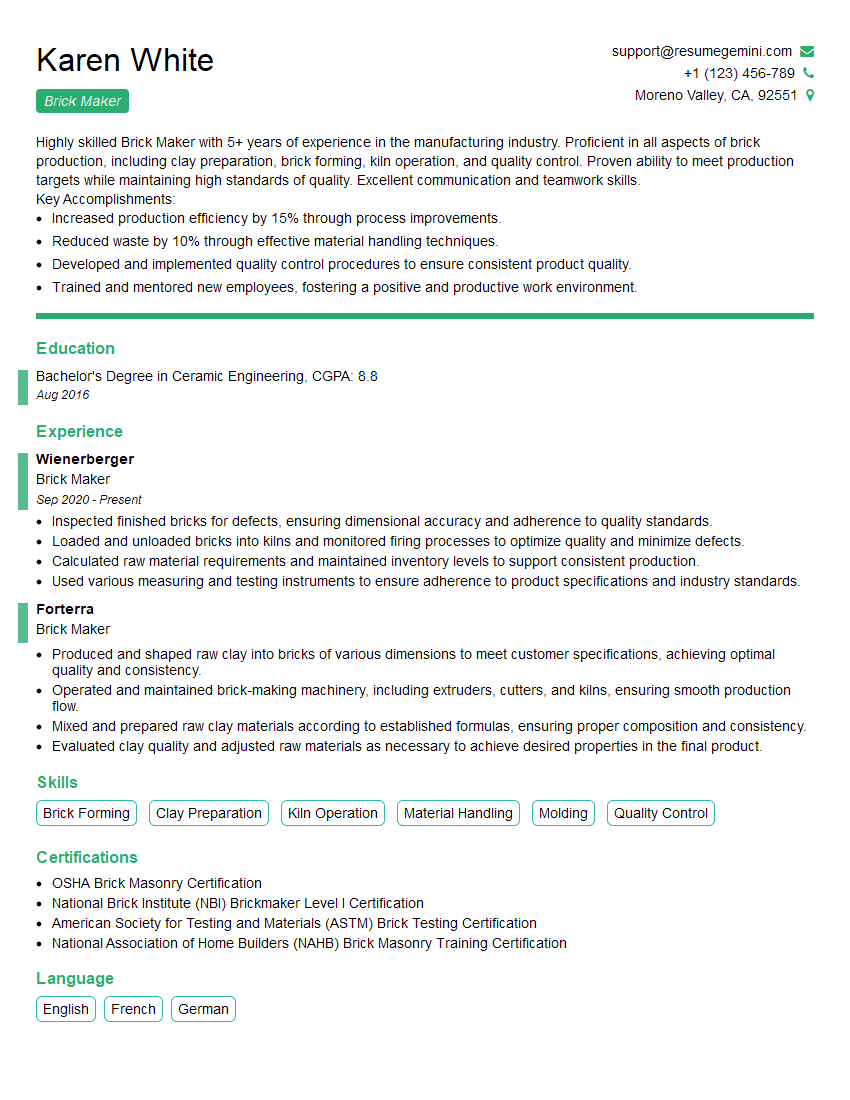

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Brick Maker

1. What are the different types of bricks and their applications?

- Common Brick: Used for general construction, such as walls, foundations, and pavements.

- Facing Brick: Used for aesthetic purposes, with smooth or textured surfaces in various colors and shapes.

- Engineering Brick: High-strength bricks used for heavy-duty structures, such as bridges and industrial buildings.

- Fire Brick: Heat-resistant bricks used in furnaces, kilns, and fireplaces.

- Concrete Brick: Durable and moisture-resistant bricks made from concrete, used in foundations, landscaping, and decorative applications.

2. Explain the process of brick making.

Raw Material Preparation

- Extraction and crushing of clay or shale.

- Addition of water to create a moldable clay mixture.

Forming

- Molding the clay mixture into bricks using presses or extruders.

- Shaping and cutting the bricks to desired sizes.

Drying

- Removing excess moisture from the bricks gradually to prevent cracking.

- Air drying or using heated chambers.

Firing

- Heating the bricks in a kiln at high temperatures.

- Fusion of clay particles and creation of interlocking crystal structures.

Cooling

- Slow and controlled cooling process to prevent thermal shock.

- Use of special cooling chambers or natural cooling in the open air.

3. Describe the qualities and properties of a good brick.

- Strength: Capable of withstanding compression and bending loads.

- Durability: Resistant to wear, weathering, and chemical attack.

- Low Water Absorption: Absorbs minimal moisture, preventing frost damage and efflorescence.

- Fire Resistance: Non-combustible and can withstand high temperatures.

- Uniformity: Consistent in size, shape, and color, ensuring proper bond and aesthetics.

- Uniform Texture: Free of cracks, voids, or imperfections that can compromise strength.

4. What factors affect the quality of bricks?

- Raw Material Quality: Composition and properties of the clay or shale used.

- Manufacturing Process: Adherence to proper techniques in forming, drying, firing, and cooling.

- Kiln Temperature: Adequate temperature and heating duration for proper sintering.

- Cooling Rate: Controlled cooling to prevent thermal stress and cracking.

- Environmental Conditions: Exposure to moisture, freezing, or chemicals during production or storage.

5. Explain the different types of bricklaying bonds.

- Stretcher Bond: Bricks laid in rows parallel to the wall face, providing a simple and durable pattern.

- Header Bond: Bricks laid with their short ends exposed on the wall face, creating a decorative appearance.

- Flemish Bond: Alternating rows of stretchers and headers, resulting in a classic and aesthetically pleasing pattern.

- English Bond: Similar to Flemish Bond, but with a running bond of stretchers in every third row between header rows.

- Stack Bond: Bricks laid vertically one above the other, creating a modern and minimalist look.

6. Describe the techniques for laying bricks in different patterns.

- Dry-Laying: Placing bricks without mortar, used for dry stone walls or as a preparatory step before setting with mortar.

- Butterflying: Spreading mortar on both sides of the brick for increased bond strength.

- Floating: Applying mortar only to the top of the brick, resulting in a flatter joint.

- Raking: Texturing the mortar joints using a tool to create different patterns and finishes.

- Tuckpointing: Repairing or repointing existing mortar joints to enhance durability and aesthetics.

7. What are the safety precautions to be considered when working with bricks?

- Wear Protective Gear: Hard hat, safety glasses, gloves, and proper clothing.

- Proper Lifting Techniques: Use mechanical equipment or proper posture to avoid injury.

- Avoid Loose Bricks: Watch out for loose or unstable bricks and take necessary precautions.

- Scaffolding Safety: Ensure proper setup and stability of scaffolding when working at heights.

- Fall Protection: Use safety harnesses and other fall protection measures as required.

8. How do you control the quality of bricks during production?

- Raw Material Testing: Performing chemical and physical tests on clay or shale to assess its suitability for brickmaking.

- Process Monitoring: Regularly checking forming, drying, firing, and cooling parameters to ensure optimal conditions.

- Brick Testing: Conducting physical and mechanical tests, such as compression strength, water absorption, and freeze-thaw cycles, to verify compliance with quality standards.

- Visual Inspection: Assessing bricks for uniformity, texture, color, and dimensional accuracy before packaging and shipment.

- Quality Assurance: Establishing quality control protocols and implementing corrective actions as needed to maintain consistent high standards.

9. What are the latest innovations or advancements in brickmaking?

- Automated Brickmaking: Use of sophisticated machinery to automate the brickmaking process, increasing efficiency and precision.

- Sustainable Brickmaking: Incorporating eco-friendly practices, such as reducing energy consumption, using recycled materials, and minimizing waste.

- Novel Materials: Exploration of alternative materials, such as recycled glass or agricultural byproducts, in brickmaking to enhance sustainability and improve properties.

- Advanced Firing Techniques: Optimizing kiln technology to improve firing efficiency and reduce emissions.

- Digital Design and 3D Printing: Integration of digital design tools and 3D printing techniques for innovative brick shapes and customized construction.

10. How do you stay up-to-date with the latest trends and developments in brickmaking?

- Attend Industry Events: Participate in conferences, trade shows, and workshops to connect with experts and learn about new technologies.

- Read Technical Publications: Subscribe to industry journals and research papers to stay informed about advancements and best practices.

- Network with Professionals: Join industry organizations and connect with peers to exchange knowledge and ideas.

- Attend Training Programs: Take courses or seminars offered by manufacturers or industry associations to enhance skills and stay current with emerging trends.

- Research Online: Utilize online resources, forums, and websites to access the latest information and case studies.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Brick Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Brick Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Brick makers are responsible for producing bricks used in construction. Their tasks involve preparing clay, molding bricks, and ensuring their quality.

1. Clay Preparation

Prepare clay by mixing it with water to create a workable paste.

- Determine the correct water-to-clay ratio to achieve the desired consistency.

- Use mixers or pug mills to blend the clay thoroughly.

2. Molding Bricks

Mold bricks using manual or automated machines.

- Operate brick-molding machines to fill molds with clay.

- Remove molded bricks from the machines and place them on drying racks.

3. Drying Bricks

Air-dry bricks in controlled conditions to remove moisture.

- Stack bricks in rows on drying racks.

- Monitor temperature and humidity levels to optimize the drying process.

4. Firing Bricks

Fire bricks in kilns to harden and strengthen them.

- Load bricks into kilns and set the firing temperature.

- Control the kiln’s atmosphere and temperature throughout the firing process.

5. Quality Control

Inspect bricks for defects and ensure they meet specifications.

- Visually examine bricks for cracks, chips, or other imperfections.

- Conduct tests to verify the strength and durability of bricks.

Interview Tips

Preparing for a brick maker interview requires understanding the job responsibilities and industry knowledge. Here are some tips to help candidates ace the interview:

1. Research the company and industry

Learn about the company’s history, values, and products. Research industry trends and technological advancements.

2. Practice common interview questions

Prepare answers to common interview questions such as “Tell me about yourself” and “Why are you interested in this position?”

3. Highlight relevant skills and experience

Emphasize your experience in clay preparation, brick molding, firing, and quality control. Mention any relevant certifications or training.

4. Demonstrate problem-solving abilities

Provide examples of how you have solved problems related to clay preparation, brick production, or quality issues.

5. Show enthusiasm and passion

Express your passion for brick making and demonstrate your commitment to producing high-quality products.

6. Ask insightful questions

Prepare thoughtful questions to ask the interviewer, showing your interest in the position and the company.

7. Dress professionally and arrive on time

First impressions matter. Dress professionally and arrive for the interview on time to demonstrate respect and punctuality.

Next Step:

Now that you’re armed with the knowledge of Brick Maker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Brick Maker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini