Are you gearing up for an interview for a Brick or Block Maker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Brick or Block Maker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

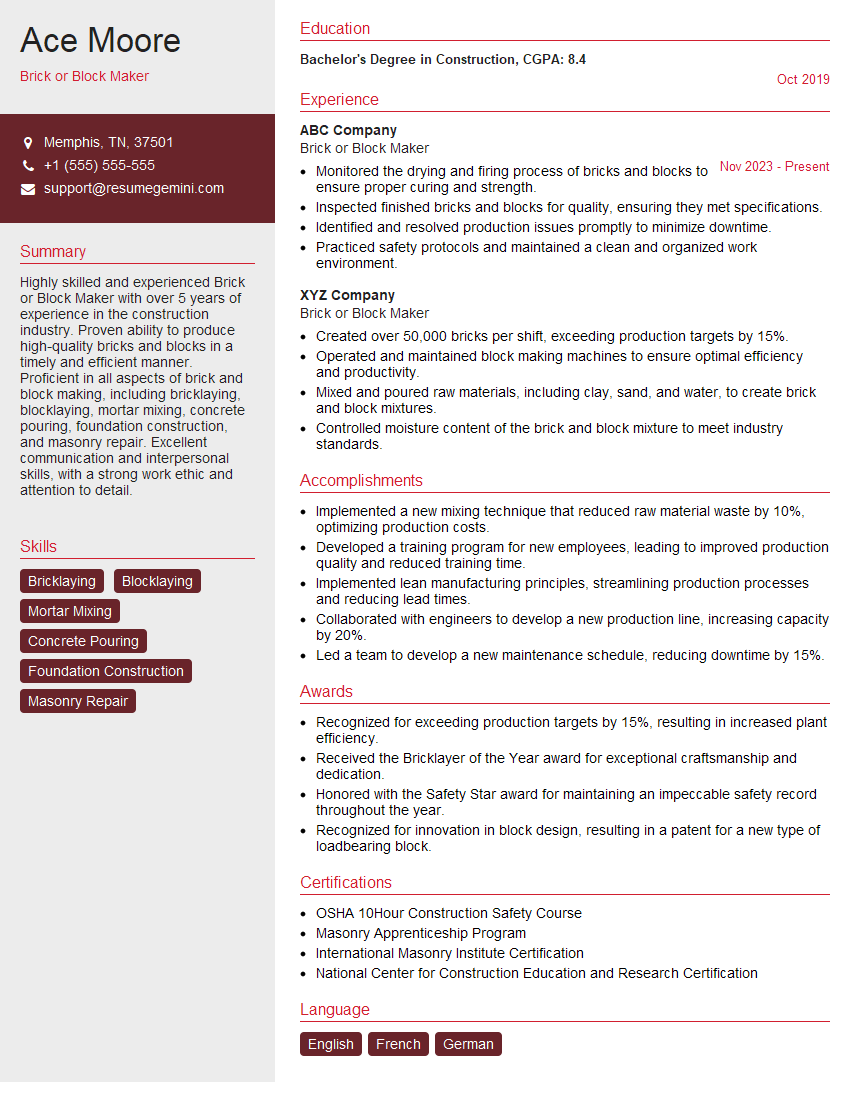

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Brick or Block Maker

1. What are the different types of bricks used in construction?

- Common Brick: These are the most basic and widely used bricks, made from clay and fired at a low temperature.

- Engineering Brick: Engineered for strength and durability, these bricks are made from high-quality clay and fired at a high temperature.

- Facing Brick: Designed for aesthetic appeal, these bricks are made from a blend of clays and are often textured or colored.

- Paving Brick: Used for outdoor applications, these bricks are strong and durable, with a non-slip surface.

- Fire Brick: Made from refractory materials, these bricks can withstand high temperatures and are used in fireplaces, furnaces, and other heat-resistant applications.

2. What are the key properties of a good brick?

- Strength: The ability to withstand compression and bending forces.

- Durability: Resistance to weathering, erosion, and chemical attack.

- Water Absorption: The amount of water the brick can absorb, which affects its resistance to freeze-thaw damage.

- Dimensional Accuracy: The consistency of the brick’s size and shape ensures proper bonding during construction.

- Color and Appearance: The aesthetic qualities of the brick, which can enhance the appearance of the finished structure.

3. What is the process of manufacturing bricks?

The process involves:

- Raw Material Selection: Selecting suitable clay or shale with the desired properties.

- Preparation: Grinding the raw material to the appropriate size and mixing it with water to form a clay slurry.

- Molding: Shaping the clay slurry into bricks using molds or extruders.

- Drying: Removing excess moisture from the bricks to prepare them for firing.

- Firing: Heating the bricks in kilns at high temperatures to harden and vitrify them.

- Cooling: Gradually cooling the bricks to prevent cracking and ensure proper tempering.

4. What equipment is used in the production of bricks?

- Jaw Crusher: For crushing raw materials to the desired size.

- Pug Mill: For mixing and kneading the clay slurry.

- Brick Molding Machine: For shaping the clay slurry into bricks.

- Drying Tunnels or Chambers: For removing excess moisture from the bricks.

- Kilns: For firing the bricks at high temperatures.

- Forklifts: For handling and transporting bricks throughout the process.

5. What are the common defects found in bricks? How can they be prevented?

- Cracks: Caused by uneven drying or improper firing.

- Efflorescence: White or colored salt deposits on the surface of bricks, caused by soluble salts.

- Warpage: Distortion of the brick shape, caused by uneven firing or mold defects.

- Bloating: Formation of bubbles or cavities within the brick, caused by gas entrapment during firing.

- Spalling: Splitting or flaking of the brick surface, caused by freeze-thaw damage or excessive moisture absorption.

Prevention measures include:

- Proper drying techniques to avoid cracks.

- Using low-salt clays and firing at appropriate temperatures to prevent efflorescence.

- Ensuring even firing temperatures and using high-quality molds to prevent warpage.

- Controlling the gas release during firing to prevent bloating.

- Selecting bricks with low water absorption to reduce spalling.

6. How do you ensure the quality of bricks produced?

- Raw Material Testing: Assessing the properties of the raw clay or shale to ensure suitability.

- Process Control: Monitoring each stage of the production process, including molding, drying, and firing, to maintain consistent quality.

- Sampling and Testing: Regularly testing samples of bricks for strength, durability, water absorption, and dimensional accuracy.

- Adherence to Standards: Complying with industry standards and regulations for brick production.

- Customer Feedback: Gathering feedback from customers and conducting site visits to evaluate the performance of bricks in real-world applications.

7. What are the different types of kilns used in brick production?

- Updraft Kilns: Bricks are stacked on a floor and heat rises from below.

- Downdraft Kilns: Heat enters from the top and travels downward through the bricks.

- Tunnel Kilns: Bricks are continuously moved through a tunnel where they are subjected to different temperatures.

- Annular Kilns: Bricks are arranged in a circular chamber that rotates gradually through different temperature zones.

- Shuttle Kilns: Bricks are placed on kiln cars that move in and out of a stationary kiln chamber.

8. What factors affect the strength of a brick?

- Clay Composition: The type and proportions of minerals present in the clay.

- Firing Temperature: The temperature and duration of firing affect the vitrification and bonding of the clay particles.

- Compaction: The density and uniformity of the brick’s structure.

- Grain Size: Smaller grain sizes contribute to increased strength.

- Additives: Certain additives, such as grog or sawdust, can enhance strength.

9. What are the environmental considerations in brick production?

- Raw Material Extraction: Responsible sourcing of clay and shale to minimize environmental impact.

- Energy Consumption: Optimizing energy efficiency in kilns and other production processes.

- Water Usage: Conserving water throughout the production process.

- Waste Management: Proper disposal of waste materials generated during production.

- Emissions Control: Implementing technologies to reduce air pollution from kilns.

10. How do you stay up-to-date on the latest advancements in brick manufacturing?

- Attending Industry Conferences and Exhibitions: Networking with professionals and learning about new technologies.

- Reading Trade Publications and Journals: Staying informed about industry news, research, and best practices.

- Participating in Online Forums and Groups: Engaging with experts and discussing emerging trends.

- Collaborating with Research Institutions: Exploring innovative materials and production techniques.

- Seeking Continuing Education Opportunities: Enrolling in courses or workshops to enhance knowledge and skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Brick or Block Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Brick or Block Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Brick or Block Makers contribute significantly to the construction sector by shaping raw materials into essential building components. Their primary duties include:

1. Raw Material Preparation

Acquire and prepare raw materials such as sand, cement, water, and aggregate to create the brick or block mixture.

- Measure and mix ingredients according to established specifications.

- Ensure adequate moisture levels for proper brick or block formation.

2. Machine Operation

Operate brick or block-making machines to mold and shape the mixture into desired forms.

- Monitor machine settings and adjust them as needed.

- Ensure consistent quality and dimensions of bricks or blocks.

3. Drying and Curing Process

Control drying and curing conditions to ensure proper hardening and strength development.

- Place bricks or blocks in designated drying areas.

- Monitor temperature and humidity levels during the drying process.

4. Packaging and Storage

Package and store finished bricks or blocks for delivery and use.

- Securely bundle bricks or blocks on pallets.

- Organize and maintain inventory in designated storage areas.

5. Maintenance and Repairs

Perform routine maintenance and repairs on brick-making machines and equipment.

- Clean and lubricate machines to ensure optimal functioning.

- Identify and resolve minor issues to prevent downtime.

Interview Tips

To ace an interview for the Brick or Block Maker position, it’s crucial to prepare effectively. Here are some key tips:

1. Research the Company and Role

Familiarize yourself with the company’s background, industry, and specific requirements for the position. This demonstrates your interest and commitment to the opportunity.

- Visit the company website and read any available materials.

- Review the job description carefully and note the essential skills and qualifications.

2. Highlight Relevant Skills and Experience

Emphasize your previous experience and skills that directly align with the job responsibilities. Provide specific examples to demonstrate your proficiency.

- Discuss your experience in raw material preparation, machine operation, or drying and curing processes.

- Highlight any knowledge of brick or block-making equipment and maintenance techniques.

3. Prepare for Industry-Specific Questions

Anticipate questions related to the industry and specific brick or block-making techniques. Research common industry practices and terminology to confidently answer these questions.

- Be prepared to discuss different types of bricks or blocks, their properties, and applications.

- Show your understanding of the quality standards and testing procedures for brick or block production.

4. Practice Common Interview Questions

Prepare for general interview questions such as “Tell me about yourself” or “Why do you want to work for our company?” Craft concise and compelling answers that highlight your strengths and qualifications.

- Think about your motivations for applying and how they align with the company’s goals.

- Prepare examples from your experience that demonstrate your teamwork, problem-solving abilities, and attention to detail.

5. Dress Professionally and Arrive Punctually

First impressions matter. Dress appropriately for the interview and arrive on time to show respect and professionalism.

- Consider wearing business casual attire or a uniform that reflects the industry.

- Allow ample time for travel and parking to avoid any last-minute stress.

Next Step:

Now that you’re armed with the knowledge of Brick or Block Maker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Brick or Block Maker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini