Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Brick Setter Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

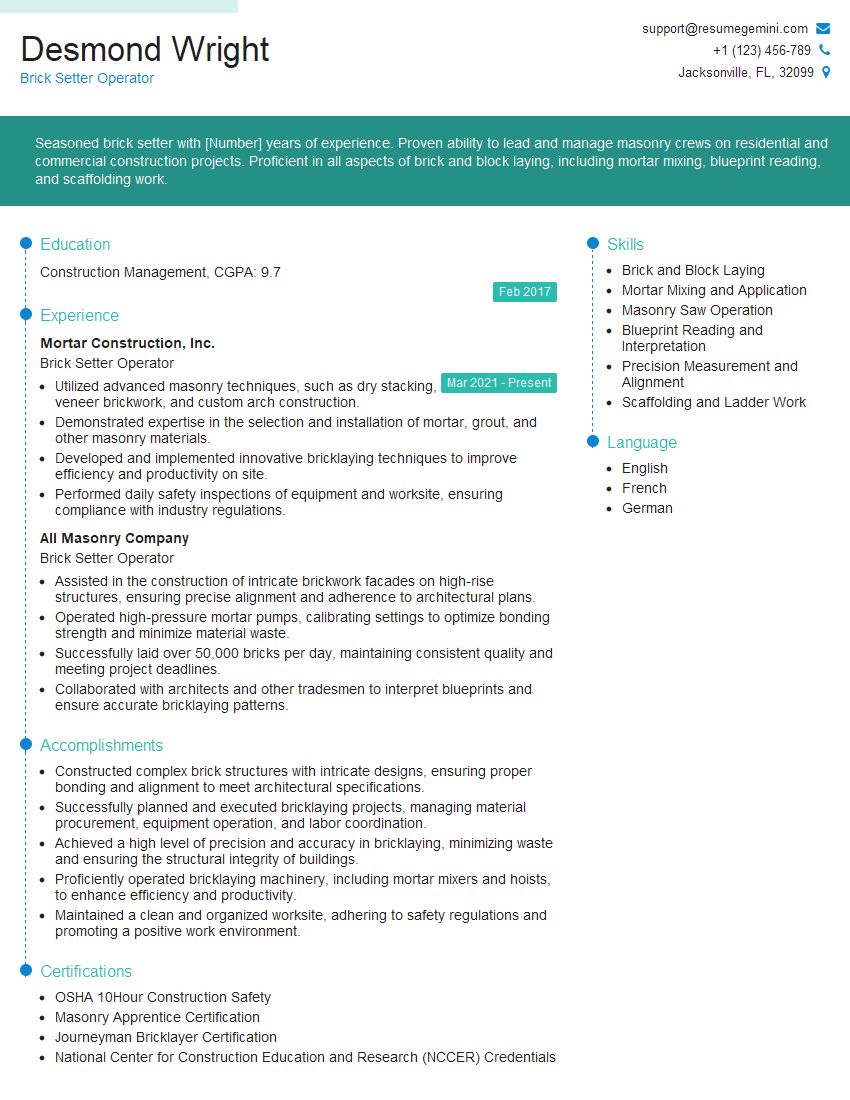

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Brick Setter Operator

1. What are the different types of bricks used in construction?

There are numerous types of bricks used in construction, each with unique properties:

- Clay Bricks: Durable, fire-resistant, and versatile for various applications.

- Concrete Bricks: Strong, low-maintenance, and ideal for load-bearing walls.

- Sand-Lime Bricks: Smooth texture, high compressive strength, and resistant to water absorption.

- Engineering Bricks: Extremely strong and durable, used for demanding applications like bridges and industrial structures.

- Facing Bricks: Aesthetically pleasing, used for exterior walls to enhance the appearance of buildings.

2. Describe the process of laying bricks in a running bond pattern.

- Step 1: Prepare the Base: Establish a level and stable base for the bricks.

- Step 2: Lay the First Row: Align the first row of bricks horizontally and vertically, using a level.

- Step 3: Lay the Second Row: Overlap the joints of the second row with the centers of the bricks in the first row, alternating the direction of the bricks.

- Step 4: Continue Laying Rows: Repeat step 3 until the desired height is achieved, maintaining the alternating pattern.

- Step 5: Fill Joints: Once all the bricks are laid, use mortar to fill the joints and create a strong bond.

3. How do you ensure that the bricks are laid level and plumb?

To ensure that the bricks are laid level and plumb, I employ the following techniques:

- Use a Level and Plumb Line: Regularly check the levelness of each brick using a level and plumb line.

- Straight Edge and Profile Board: Use a straight edge or profile board to guide the placement of bricks, ensuring they are aligned horizontally and vertically.

- Adjust Mortar Thickness: Adjust the thickness of the mortar bed to compensate for any irregularities in the bricks.

- Tap Bricks into Place: Use a rubber mallet to lightly tap the bricks into place, ensuring they are level and snug against each other.

4. What are the common challenges faced by Brick Setter Operators?

- Uneven Surfaces: Leveling bricks on uneven surfaces requires additional care and precision.

- Weather Conditions: Extreme temperatures and precipitation can affect the workability of mortar and the setting time of bricks.

- Complex Patterns: Laying bricks in intricate patterns requires accuracy and attention to detail.

- Time Constraints: Meeting project deadlines while maintaining quality standards can be challenging.

- Physical Demands: The job involves lifting heavy bricks and working in physically demanding positions.

5. Describe the safety precautions you take when operating a brick saw.

- Wear Protective Gear: Wear proper safety gear, including gloves, eye protection, and a dust mask.

- Check the Machine: Inspect the saw’s electrical cord, blade, and water supply before operating it.

- Secure the Brick: Secure the brick firmly on the saw’s cutting table to prevent it from moving during the cut.

- Control the Blade: Hold the saw firmly and guide it slowly through the brick, avoiding sudden movements or excessive pressure.

- Avoid Kickback: Be aware of the potential for kickback and position yourself accordingly.

6. How do you handle a situation where a brick is chipped or damaged during cutting?

When a brick is chipped or damaged during cutting, I take the following steps:

- Determine the Severity: Assess the extent of the damage and determine if the brick is still usable.

- Repair Minor Chips: If the chips are minor, I may use a grinder to smooth the edges and make them less noticeable.

- Replace the Brick: If the damage is significant, I will replace the damaged brick with a new one.

- Inform the Supervisor: I will inform my supervisor about the damaged brick and the steps taken to address it.

7. What are the different ways to join bricks together?

- Mortar: The most common method, using a mixture of sand, cement, and water to bind the bricks together.

- Dry Stacking: Bricks are stacked without mortar, relying on friction and interlocking to hold them in place.

- Interlocking Bricks: Bricks specifically designed with interlocking shapes to create a stable and secure bond.

- Adhesive: Special construction adhesives can be used to bond bricks, often for non-load-bearing applications.

8. How do you prepare a mortar mix for bricklaying?

- Calculate Proportions: Determine the appropriate ratio of sand to cement based on the project requirements.

- Mix Dry Ingredients: Thoroughly mix the sand and cement in a dry state.

- Add Water Gradually: Gradually add water to the dry mix while mixing until the desired consistency is achieved.

- Check the Consistency: The mortar should be workable but not too wet or too dry.

- Use Mortar Promptly: Use the mortar as soon as possible, as it will start to set over time.

9. What tools and equipment are essential for a Brick Setter Operator?

- Brick Trowel: Used for applying and spreading mortar.

- Level and Plumb Line: To ensure level and vertical alignments.

- Brick Saw: For cutting and shaping bricks.

- Jointer: To create smooth and even joints between bricks.

- Safety Gear: Gloves, eye protection, and protective footwear.

10. How do you stay updated with advancements in bricklaying techniques and materials?

- Attend Industry Events: Participate in conferences, workshops, and trade shows to learn about new technologies.

- Read Industry Publications: Stay informed by reading trade magazines, journals, and online articles.

- Consult with Experts: Seek advice and guidance from experienced bricklayers and engineers.

- Online Training and Certifications: Utilize online platforms to enhance skills and obtain industry-recognized certifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Brick Setter Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Brick Setter Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Brick Setter Operators are responsible for operating and maintaining equipment used to set bricks, blocks, and other masonry materials in construction projects. They must ensure the accuracy and precision of their work to meet building codes and specifications.

1. Equipment Operation

Operate and maintain brick-setting machines, including adjusting settings and troubleshooting any mechanical issues.

- Control the flow of bricks or blocks from the machine to the work area.

- Monitor the machine’s performance and make necessary adjustments to ensure optimal operation.

2. Masonry Installation

Set bricks or blocks in designated areas, using mortar or other bonding materials to secure them.

- Ensure that bricks or blocks are aligned properly and meet building specifications.

- Fill joints between bricks or blocks with mortar or grout and smooth excess material.

3. Quality Control

Inspect completed masonry work to ensure adherence to building codes and specifications.

- Check the levelness and plumbness of walls and other masonry structures.

- Identify and correct any defects or irregularities in the masonry work.

4. Safety and Equipment Maintenance

Follow safety regulations and wear appropriate protective gear while operating equipment.

- Perform routine maintenance on brick-setting machines and other related equipment.

- Clean and lubricate equipment regularly to ensure optimal performance.

Interview Tips

Preparing for a Brick Setter Operator interview requires a combination of research, practice, and showcasing your relevant skills and experience.

1. Research the Company and Position

Thoroughly research the construction company and the specific role you are applying for. Understand the company’s mission, values, and the nature of the projects they undertake.

- Identify the key requirements for the position and tailor your resume and answers accordingly.

- Familiarize yourself with industry trends and best practices in brick setting.

2. Practice Your Responses

Common interview questions for Brick Setter Operators focus on technical skills, safety protocols, and teamwork abilities. Anticipate these questions and prepare concise, well-structured answers that highlight your proficiency.

- Use the STAR method to answer behavioral questions, providing specific examples of your work.

- Rehearse your answers aloud to improve your delivery and confidence.

3. Emphasize Safety and Quality

Safety is paramount in construction, and interviewers will be keen on assessing your commitment to adhering to safety regulations. Showcase your knowledge of industry-standard safety protocols and your track record of maintaining a safe work environment.

- Highlight instances where you proactively identified and mitigated safety risks.

- Explain how you stay up-to-date with safety regulations and best practices.

4. Demonstrate Teamwork and Communication

Brick Setter Operators often work as part of a team, collaborating with other tradespeople. Emphasize your ability to work effectively in a team environment, communicate clearly, and adapt to changing project requirements.

- Provide examples of successful collaborations with other team members.

- Explain how you handle conflicts or challenges that arise during a project.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Brick Setter Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.