Are you gearing up for a career in Brick Stacker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Brick Stacker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

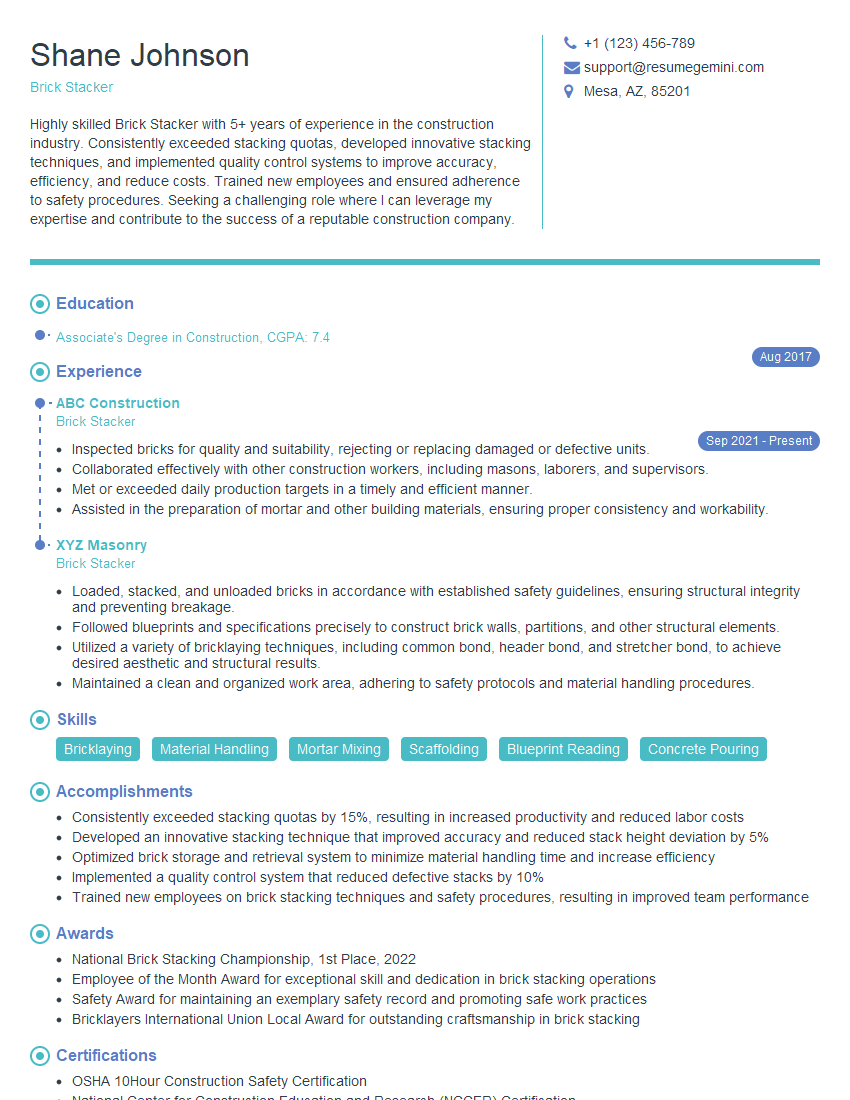

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Brick Stacker

1. What are the different types of bricks used in construction, and which one is most suitable for a load-bearing wall?

There are various types of bricks used in construction, depending on the application and specific requirements. Here are some common types of bricks:

- Clay bricks: Made from clay, these bricks are durable, fire-resistant, and versatile. They are often used in load-bearing walls and exterior applications.

- Concrete bricks: As the name suggests, these bricks are made from concrete and are known for their high strength and durability. They are often used in foundations, retaining walls, and other structural applications.

- Sand-lime bricks: These bricks are made from a mixture of sand and lime, and are known for their smooth surface and uniform shape. They are often used in interior walls and partitions.

- Fly ash bricks: Made from fly ash, a byproduct of coal combustion, these bricks are lightweight and environmentally friendly. They are often used in non-load-bearing walls and as fillers in cavity walls.

For a load-bearing wall, which carries the structural load of the building, clay bricks or concrete bricks are typically the most suitable choices due to their high strength and durability.

2. What is the recommended mortar mix ratio for bricklaying?

- For general purpose bricklaying: A mix ratio of 1 part cement to 4 parts sand is commonly used. This provides a good balance of strength, workability, and cost-effectiveness.

- For heavy-duty applications: A mix ratio of 1 part cement to 3 parts sand can be used for increased strength, but it may require more water and be more difficult to work with.

- For thin-bed mortar: A mix ratio of 1 part cement to 6 parts sand is used, along with a plasticizer, to create a thin layer of mortar between the bricks.

It is important to follow the manufacturer’s instructions and adjust the mix ratio as needed based on the specific bricks and application.

3. What is the proper technique for laying bricks in a running bond pattern?

- Start by laying the first course of bricks with all the bricks aligned end-to-end, creating a straight line.

- For the second course, offset the bricks by half their length, so that the joints between the bricks in the first course are centered under the bricks in the second course.

- Continue this pattern for each subsequent course, alternating the starting position of the bricks to create a staggered effect.

- Ensure that the vertical joints between the bricks are aligned to create a neat and stable wall.

Running bond is a common bricklaying pattern that provides strength and stability to the wall.

4. How do you ensure that a brick wall is level and plumb?

- Level: Use a spirit level to check the horizontality of each course of bricks as you lay them. Adjust the mortar bed or tap the bricks gently to level them.

- Plumb: Use a plumb bob or laser level to check the verticality of the wall. Adjust the alignment of the bricks as needed to ensure that the wall is straight and perpendicular to the ground.

- String lines: String lines can be used as guides to help maintain level and plumb throughout the wall.

Ensuring a level and plumb wall is crucial for the structural integrity and appearance of the building.

5. What are the safety precautions that should be taken while bricklaying?

- Wear appropriate safety gear, including gloves, safety glasses, and a hard hat.

- Use proper lifting techniques to avoid back injuries when handling bricks.

- Be aware of the surroundings and potential hazards such as uneven surfaces or electrical wires.

- Store bricks securely to prevent them from falling and causing injuries.

- Follow proper scaffolding and ladder safety guidelines when working at heights.

Adhering to safety precautions helps prevent accidents and ensures a safe working environment.

6. What are the different types of bricklaying tools and their uses?

- Trowel: Used for spreading, shaping, and smoothing mortar.

- Brick hammer: Used for cutting and shaping bricks.

- Level: Used for checking the horizontality of brick courses.

- Plumb bob or laser level: Used for checking the verticality of walls.

- Jointer: Used for shaping and smoothing mortar joints.

- Bolster: Used for supporting bricks while cutting or shaping them.

Understanding the purpose and proper use of these tools is essential for efficient and effective bricklaying.

7. What is the importance of curing bricks after they are laid?

- Curing allows the mortar to set and gain strength, which is crucial for the structural integrity of the wall.

- Proper curing prevents the mortar from drying out too quickly, which can lead to cracking and weakening.

- Curing helps to ensure that the mortar bonds properly with the bricks, creating a durable and long-lasting structure.

Curing can be done by protecting the bricks from direct sunlight and wind, and by keeping them moist for a specified period of time.

8. What are the advantages of using brick veneer over solid brick walls?

- Cost-effectiveness: Brick veneer is less expensive than solid brick walls, as it uses less material and labor.

- Variety of finishes: Brick veneer allows for a wider range of colors, textures, and patterns, providing more design options.

- Energy efficiency: When combined with proper insulation, brick veneer can contribute to the overall energy efficiency of a building.

- Lightweight: Brick veneer is lighter than solid brick walls, reducing the structural load on the building’s foundation.

Brick veneer is a cost-effective and versatile option that combines the aesthetic appeal of brick with the benefits of modern building materials.

9. What are the common maintenance tasks required for brick walls?

- Regular cleaning: Periodic cleaning helps remove dirt, grime, and efflorescence (white deposits) from the brick surface.

- Repointing: Over time, mortar joints may deteriorate and need to be repaired or replaced, a process known as repointing.

- Waterproofing: In areas with high moisture, applying a water-repellent sealant can help protect the brick wall from water damage.

- Tuckpointing: This technique involves removing damaged mortar and replacing it with new mortar, providing a fresh and clean appearance to the wall.

Proper maintenance helps extend the lifespan and preserve the aesthetic appeal of brick walls.

10. What is the difference between common brick and face brick?

- Common brick: Typically used for interior applications or hidden portions of walls, common brick is less expensive and has a more rustic appearance.

- Face brick: Designed for exterior use and visible surfaces, face brick is more aesthetically pleasing, has a uniform shape and texture, and is more durable.

The choice between common brick and face brick depends on the specific application and desired aesthetic.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Brick Stacker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Brick Stacker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Brick stackers are responsible for loading, unloading, and stacking bricks at construction sites. They typically work with a team of other laborers to move and stack bricks according to plans and specifications.

1. Loading and unloading bricks

Brick stackers use forklifts or other equipment to load and unload bricks from trucks or other vehicles. They may also need to move bricks by hand.

- Operate forklifts and other equipment to load and unload bricks.

- Move bricks by hand when necessary.

2. Stacking bricks

Brick stackers stack bricks in neat, orderly rows according to plans and specifications. They use a variety of tools and techniques to ensure that the bricks are stacked correctly and securely.

- Stack bricks in neat, orderly rows according to plans and specifications.

- Use a variety of tools and techniques to ensure that the bricks are stacked correctly and securely.

3. Cleaning up the work area

Brick stackers are responsible for cleaning up their work area at the end of the day. They may need to sweep or shovel up debris, and they may also need to stack empty pallets.

- Sweep or shovel up debris.

- Stack empty pallets.

4. Maintaining equipment

Brick stackers are responsible for maintaining their equipment in good working condition. They may need to perform minor repairs or adjustments, and they may also need to clean and lubricate the equipment.

- Perform minor repairs or adjustments to equipment.

- Clean and lubricate equipment.

Interview Tips

Preparing for an interview can be nerve-wracking, but it doesn’t have to be. Here are a few tips to help you ace your interview for a brick stacker position:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, and it will also help you answer questions about your qualifications and experience.

- Visit the company’s website to learn about their history, mission, and values.

- Read online reviews of the company to get a sense of what it is like to work there.

- Talk to people in your network who work for the company or who have worked there in the past.

2. Practice answering common interview questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Write out your answers to common interview questions and practice saying them out loud.

- Ask a friend or family member to mock interview you.

- Attend a job fair or workshop where you can practice your interviewing skills.

3. Dress professionally and arrive on time

Your appearance and punctuality will make a good impression on the interviewer. Dress professionally, and arrive for your interview on time. It is also important to be polite and respectful to everyone you meet, including the receptionist and other employees.

- Choose clothing that is clean, pressed, and appropriate for a construction environment.

- Arrive for your interview at least 10 minutes early.

- Be polite and respectful to everyone you meet.

4. Be enthusiastic and positive

Interviewers are looking for candidates who are enthusiastic and positive about the job. Show the interviewer that you are excited about the opportunity to work for the company and that you are confident in your abilities.

- Smile and make eye contact with the interviewer.

- Speak clearly and confidently.

- Be positive and enthusiastic about the job.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Brick Stacker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!