Are you gearing up for an interview for a Brick Washer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Brick Washer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

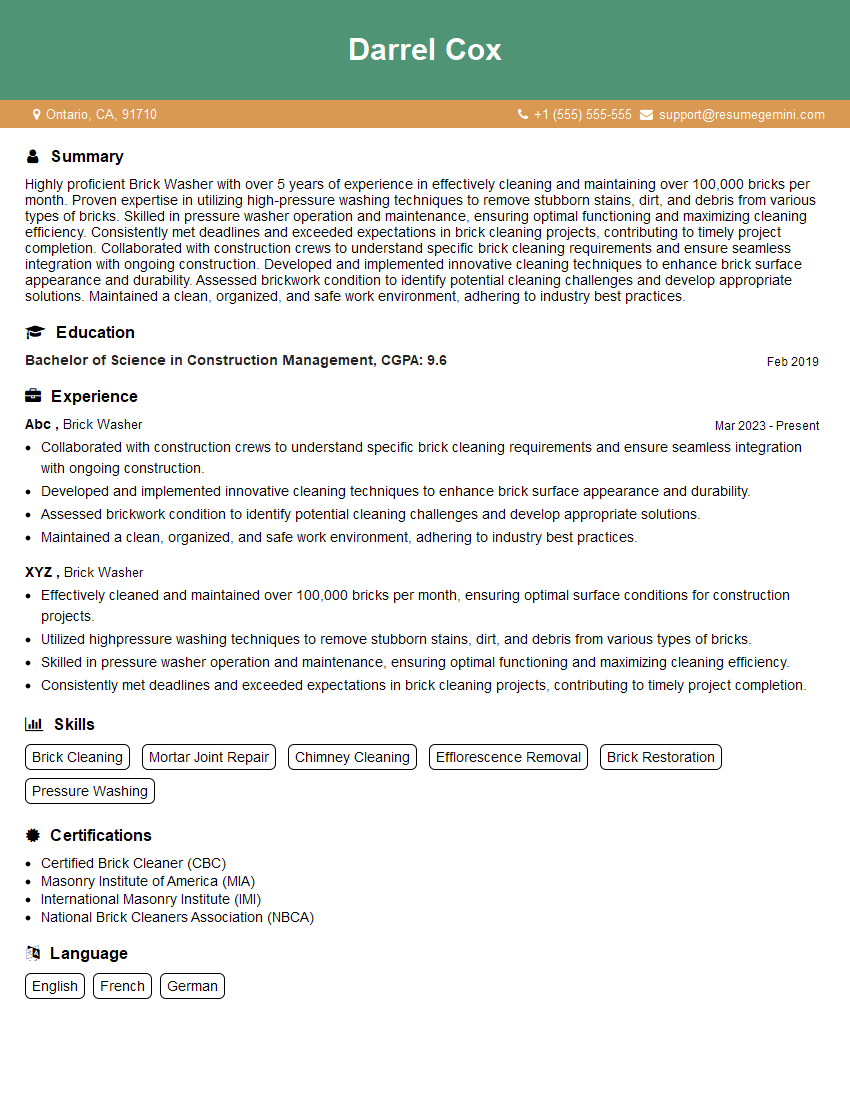

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Brick Washer

1. What are the different types of brick washing machines?

- Horizontal drum machines: These machines have a horizontal drum that rotates the bricks, while water and chemicals are sprayed onto them.

- Vertical drum machines: These machines have a vertical drum that rotates the bricks, while water and chemicals are sprayed onto them from above.

- Batch machines: These machines wash a batch of bricks at a time, and the washing process is completed before the next batch is loaded.

- Continuous machines: These machines wash bricks continuously, and the bricks are fed into and out of the machine on a conveyor belt.

2. What are the advantages and disadvantages of each type of machine?

Advantages of horizontal drum machines

- They are relatively inexpensive to purchase and operate.

- They are easy to maintain.

- They are suitable for washing a wide variety of bricks.

Disadvantages of horizontal drum machines

- They can be noisy.

- They can be slow.

- They can damage delicate bricks.

Advantages of vertical drum machines

- They are more efficient than horizontal drum machines.

- They are less noisy than horizontal drum machines.

- They are more gentle on delicate bricks.

Disadvantages of vertical drum machines

- They are more expensive to purchase and operate than horizontal drum machines.

- They are more difficult to maintain than horizontal drum machines.

- They are not suitable for washing all types of bricks.

Advantages of batch machines

- They are relatively inexpensive to purchase and operate.

- They are easy to maintain.

- They are suitable for washing small batches of bricks.

Disadvantages of batch machines

- They can be slow.

- They are not suitable for washing large batches of bricks.

Advantages of continuous machines

- They are fast and efficient.

- They are suitable for washing large batches of bricks.

Disadvantages of continuous machines

- They are more expensive to purchase and operate than batch machines.

- They are more difficult to maintain than batch machines.

3. What are the different types of chemicals used in brick washing?

- Alkaline cleaners: These chemicals are used to remove dirt and grime from bricks.

- Acid cleaners: These chemicals are used to remove efflorescence from bricks.

- Etching agents: These chemicals are used to remove the surface layer of bricks.

- Neutralizers: These chemicals are used to neutralize the effects of alkaline and acid cleaners.

4. How do you determine the correct chemical concentration for brick washing?

- The chemical manufacturer’s instructions should be followed.

- The type of brick being washed should be considered.

- The desired results should be considered.

5. What are the safety precautions that must be taken when using chemicals for brick washing?

- Wear appropriate personal protective equipment, such as gloves, goggles, and a respirator.

- Follow the chemical manufacturer’s instructions.

- Do not mix different chemicals together unless specifically instructed to do so by the manufacturer.

- Dispose of chemicals properly.

6. What are the different types of brushes used in brick washing?

- Natural fiber brushes: These brushes are made from natural fibers, such as horsehair or tampico.

- Synthetic fiber brushes: These brushes are made from synthetic fibers, such as nylon or polyester.

- Wire brushes: These brushes are made from wire, such as steel or brass.

7. How do you choose the right brush for brick washing?

- The type of brick being washed should be considered.

- The desired results should be considered.

- The cost of the brush should be considered.

8. How do you maintain your brick washing equipment?

- Follow the manufacturer’s instructions.

- Clean the equipment regularly.

- Inspect the equipment for damage.

- Lubricate the equipment as needed.

9. What are the common problems that can occur with brick washing equipment?

- Clogged nozzles

- Broken brushes

- Leaking pumps

- Electrical problems

10. How do you troubleshoot problems with brick washing equipment?

- Follow the manufacturer’s instructions.

- Inspect the equipment for damage.

- Clean the equipment.

- Replace any damaged parts.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Brick Washer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Brick Washer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Brick Washers are responsible for cleaning and preparing bricks for use in construction and other projects. They operate and maintain equipment used to clean bricks, including pressure washers and conveyor belts. Brick Washers also inspect bricks for defects and remove any debris or foreign matter.

1. Operate and maintain equipment

Brick Washers must be able to operate and maintain a variety of equipment used in the brick cleaning process, including pressure washers, conveyor belts, and forklifts. They must also be able to troubleshoot and repair minor equipment problems.

- Operate pressure washers to clean bricks

- Maintain and repair conveyor belts

- Inspect and clean forklifts

2. Inspect bricks for defects

Brick Washers must be able to inspect bricks for defects, such as cracks, chips, and discoloration. They must also be able to identify and remove any debris or foreign matter from the bricks.

- Inspect bricks for cracks, chips, and discoloration

- Identify and remove any debris or foreign matter

- Sort bricks by size, color, and quality

3. Prepare bricks for use

Brick Washers must be able to prepare bricks for use in construction and other projects. This may involve stacking bricks on pallets, loading them onto trucks, or delivering them to customers.

- Stack bricks on pallets

- Load bricks onto trucks

- Deliver bricks to customers

4. Maintain a clean and safe work environment

Brick Washers must be able to maintain a clean and safe work environment. This may involve sweeping floors, cleaning equipment, and disposing of waste materials.

- Sweep floors

- Clean equipment

- Dispose of waste materials

Interview Tips

Preparing for a brick washer interview can be daunting, but with the right tips and practice, you can increase your chances of success. Here are a few things you can do to prepare:

1. Research the company and the position

Take some time to research the company you’re applying to and the specific position you’re interested in. This will help you understand the company’s culture, values, and goals, and it will also help you tailor your answers to the interviewer’s questions.

- Visit the company’s website

- Read online reviews of the company

- Talk to people who work for the company

2. Practice answering common interview questions

There are a few common interview questions that you’re likely to be asked, regardless of the position you’re applying for. Practicing answering these questions will help you feel more confident and prepared during your interview.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

3. Prepare questions to ask the interviewer

Asking the interviewer questions is a great way to show that you’re interested in the position and the company. It also gives you an opportunity to learn more about the company and the position, and it can help you make a decision about whether or not the position is a good fit for you.

- What are the biggest challenges facing the company right now?

- What are the opportunities for advancement within the company?

- What is the company culture like?

4. Dress professionally and arrive on time

First impressions matter, so it’s important to dress professionally and arrive on time for your interview. This will show the interviewer that you’re serious about the position and that you respect their time.

- Wear a suit or business casual attire

- Be on time for your interview

- Make eye contact with the interviewer

Next Step:

Now that you’re armed with the knowledge of Brick Washer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Brick Washer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini