Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Bridge Repair Crew Person position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

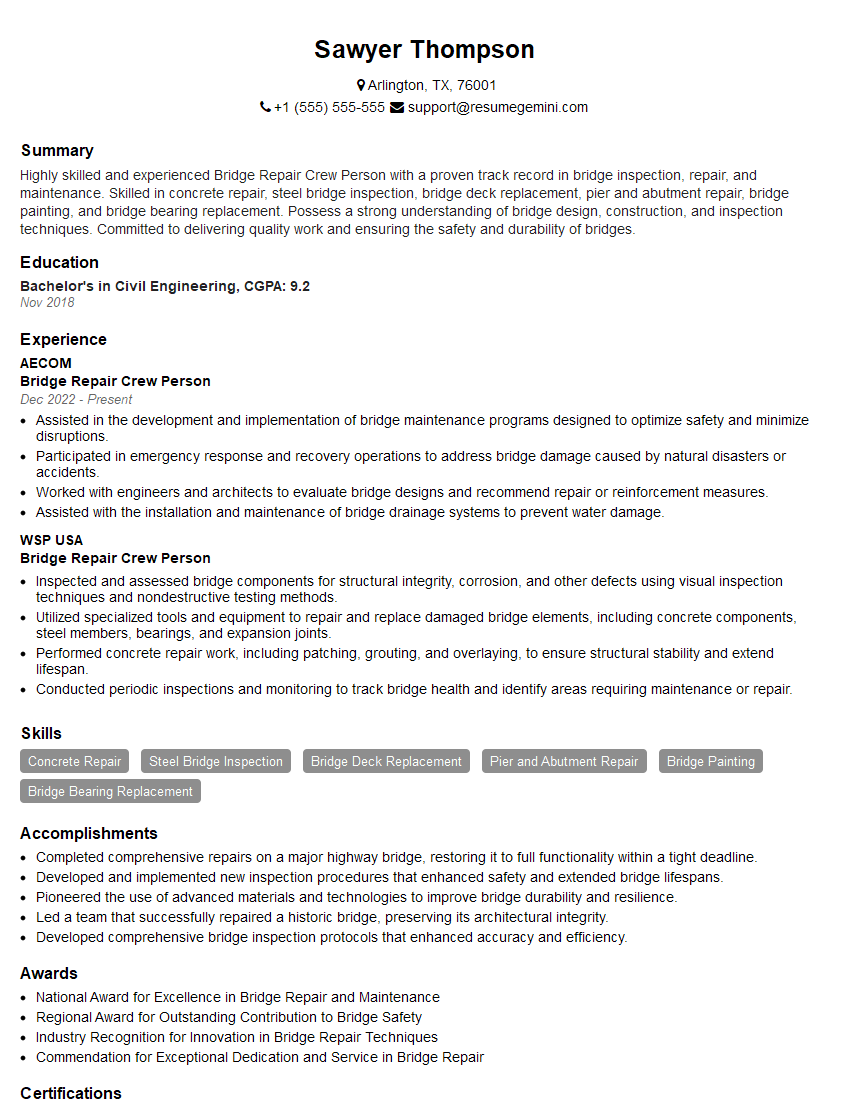

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bridge Repair Crew Person

1. What are the key responsibilities of a Bridge Repair Crew Person?

As a qualified Bridge Repair Crew Person, my responsibilities include:

- Performing repairs, maintenance, and inspections of bridges and their components, such as decks, piers, and abutments

- Identifying and evaluating bridge defects and damage, and recommending appropriate repair strategies

- Using a variety of tools and equipment to repair and replace bridge components, including concrete, steel, and timber

- Maintaining safety at all times, including wearing appropriate personal protective equipment (PPE) and following established safety procedures

- Working collaboratively with other crew members and supervisors to complete projects efficiently and effectively

2. What are the different types of bridge repair methods?

Concrete Repair

- Spall repair: Removing damaged concrete and replacing it with new concrete or a patching material

- Crack repair: Filling cracks with epoxy, polyurethane, or other materials to prevent water penetration and further damage

Steel Repair

- Rust removal and painting: Removing rust from steel beams and girders and applying a protective coating

- Welding: Repairing cracks or damaged sections of steel components by welding new material in place

Timber Repair

- Wood replacement: Replacing damaged or rotted timber planks or beams with new timber

- Preservative treatment: Applying chemicals to timber to protect it from decay and insects

3. What are the safety precautions that need to be taken when repairing bridges?

- Wearing appropriate PPE, including hard hats, safety glasses, gloves, and high-visibility clothing

- Following established safety procedures, such as using proper lifting equipment and working from stable platforms

- Maintaining a clean and organized work area to prevent tripping or falling hazards

- Being aware of potential hazards such as electrical wires, falling objects, and moving vehicles

- Communicating effectively with other crew members and supervisors to ensure everyone is aware of potential risks

4. What are the challenges associated with bridge repair work?

- Working in difficult and often dangerous conditions, such as heights, extreme weather, and confined spaces

- Dealing with unexpected problems or delays that can affect project timelines and costs

- Coordinating with other trades and contractors to ensure that repairs are completed efficiently and effectively

- Balancing the need for thorough repairs with the need to minimize traffic disruptions and maintain public safety

- Working within budget constraints and adhering to strict industry standards and regulations

5. How do you prioritize bridge repair projects?

- Evaluating the severity of the damage and the potential impact on public safety

- Considering the age and condition of the bridge and its components

- Prioritizing repairs that will extend the life of the bridge and minimize future maintenance costs

- Working within available budget constraints and resource limitations

- Coordinating with transportation agencies and other stakeholders to minimize traffic disruptions and maintain public access

6. What are the advantages of using precast concrete components in bridge repair?

- Improved quality control: Precast components are manufactured in a controlled environment, ensuring consistent quality and durability

- Faster installation: Precast components can be quickly and easily installed, reducing labor costs and project timelines

- Reduced traffic disruptions: Precast components can be installed with minimal impact on traffic flow, minimizing public inconvenience

- Increased durability: Precast components are designed to withstand harsh weather conditions and heavy loads, extending the life of the bridge

- Cost savings: Precast components can be more cost-effective than traditional cast-in-place concrete, especially for complex or repetitive repairs

7. How do you assess the structural integrity of a bridge?

- Visual inspection: Examining the bridge for cracks, spalling, corrosion, or other signs of damage

- Load testing: Applying controlled loads to the bridge to measure its deflection and load-carrying capacity

- Non-destructive testing: Using techniques such as ultrasonic testing or ground-penetrating radar to detect hidden defects or damage

- Reviewing maintenance and inspection records: Analyzing historical data to identify trends and potential areas of concern

- Consulting with structural engineers: Seeking expert advice to assess complex structural issues and develop appropriate repair strategies

8. What are the key factors to consider when selecting repair materials for bridge structures?

- Compatibility with the existing structure: Choosing materials that are compatible with the existing bridge materials to ensure proper bonding and performance

- Durability and longevity: Selecting materials that can withstand the harsh environmental conditions and heavy loads experienced by bridges

- Strength and load-bearing capacity: Ensuring that the materials have sufficient strength to meet the structural requirements of the bridge

- Ease of installation and maintenance: Opting for materials that can be easily installed and maintained, minimizing labor costs and project timelines

- Cost and availability: Considering the overall cost and availability of the materials within the project budget

9. How do you stay up-to-date with the latest bridge repair techniques and technologies?

- Attending industry conferences and webinars

- Reading technical journals and publications

- Participating in training programs offered by manufacturers and industry organizations

- Seeking certifications and accreditations to demonstrate my knowledge and skills

- Networking with other bridge repair professionals and sharing best practices

10. How do you ensure quality control in your bridge repair work?

- Following established industry standards and specifications

- Inspecting materials and components before and during installation

- Testing repairs to verify their structural integrity and performance

- Documenting all repair work and maintaining detailed records

- Seeking feedback from clients and supervisors to identify areas for improvement

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bridge Repair Crew Person.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bridge Repair Crew Person‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bridge Repair Crew Persons are responsible for the maintenance and repair of bridges. They work under the supervision of a bridge inspector or engineer and may be required to work in all types of weather conditions.

1. Inspect bridges for damage

Bridge Repair Crew Persons inspect bridges for damage on a regular basis. They look for cracks, rust, and other signs of wear and tear. They also check the condition of the bridge deck, railings, and supports.

- Use a variety of tools and equipment to inspect bridges, including ladders, flashlights, and cameras.

- Identify and document any damage found during inspections.

2. Repair bridges

Bridge Repair Crew Persons repair bridges that have been damaged. They may use a variety of techniques to repair bridges, including welding, painting, and replacing damaged parts.

- Use a variety of tools and equipment to repair bridges, including welding torches, power tools, and hand tools.

- Follow safety protocols and procedures when repairing bridges.

3. Maintain bridges

Bridge Repair Crew Persons maintain bridges by cleaning them, painting them, and making minor repairs. They also inspect bridges for damage on a regular basis.

- Use a variety of tools and equipment to maintain bridges, including brooms, brushes, and paint sprayers.

- Follow safety protocols and procedures when maintaining bridges.

4. Other duties

Bridge Repair Crew Persons may also be required to perform other duties, such as:

- Assist with bridge inspections.

- Operate and maintain bridge equipment.

- Clear debris from bridges.

Interview Tips

To ace your interview for a Bridge Repair Crew Person position, you should be prepared to discuss your experience and skills in the following areas:

1. Bridge inspection

You should be able to describe the different types of bridge inspections that you have performed and the tools and equipment that you have used.

- Practice describing your experience with bridge inspections in a clear and concise way.

- Be prepared to answer questions about the different types of damage that you have identified during bridge inspections.

2. Bridge repair

You should be able to describe the different types of bridge repairs that you have performed and the tools and equipment that you have used.

- Practice describing your experience with bridge repairs in a clear and concise way.

- Be prepared to answer questions about the different types of damage that you have repaired on bridges.

3. Bridge maintenance

You should be able to describe the different types of bridge maintenance that you have performed and the tools and equipment that you have used.

- Practice describing your experience with bridge maintenance in a clear and concise way.

- Be prepared to answer questions about the different types of maintenance tasks that you have performed on bridges.

4. Other skills

You should also be prepared to discuss your skills in the following areas:

- Working in a team environment.

- Following safety protocols and procedures.

- Using a variety of tools and equipment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bridge Repair Crew Person interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.