Are you gearing up for a career in Bridge Saw Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Bridge Saw Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

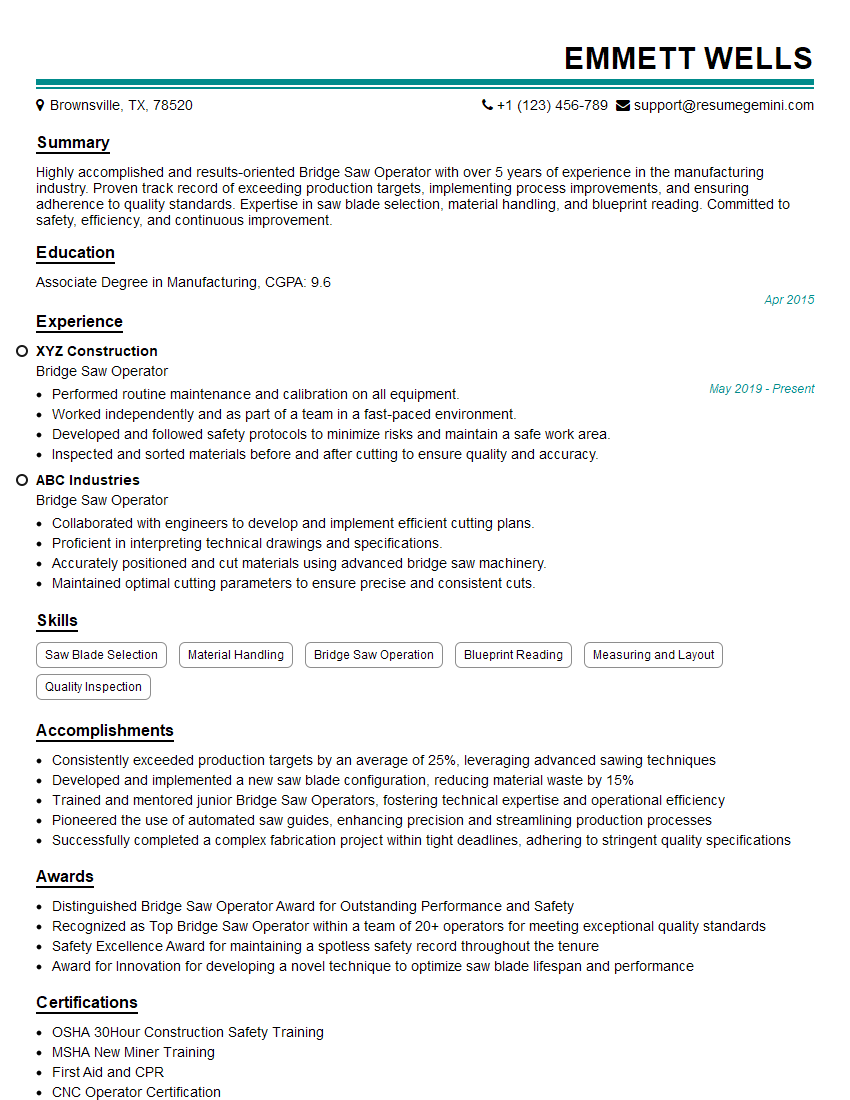

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bridge Saw Operator

1. Describe the primary responsibilities of a Bridge Saw Operator?

As a Bridge Saw Operator, my main responsibilities would include:

- Operating and maintaining a bridge saw to cut and shape materials such as wood, metal, and plastic.

- Interpreting blueprints and work orders to determine cutting specifications.

- Selecting and installing the appropriate saw blades and tools for the job.

2. Can you explain the different types of bridge saws and their applications?

Horizontal Bridge Saws

- Used for cutting large sheets of material, such as plywood, MDF, and laminates.

- Capable of making precise cuts with minimal chipping or tear-out.

Vertical Bridge Saws

- Designed for cutting smaller pieces of material, such as moldings, frames, and panels.

- Offers greater precision and control, allowing for intricate cuts and miters.

CNC Bridge Saws

- Computer-controlled saws that provide high precision and repeatability.

- Used for cutting complex shapes and angles in a variety of materials.

3. What factors should be considered when selecting saw blades for bridge saws?

- Material being cut

- Thickness of the material

- Desired cut quality

- Blade diameter and arbor size

- Number of teeth and tooth shape

4. How do you ensure the accuracy and precision of cuts made on a bridge saw?

- Properly aligning the material and saw blade before cutting.

- Using sharp and high-quality saw blades.

- Adjusting the saw speed and feed rate according to the material being cut.

- Checking cuts regularly with measuring tools such as calipers or rulers.

5. What safety precautions should be taken when operating a bridge saw?

- Wearing appropriate safety gear, such as safety glasses, earplugs, and gloves.

- Ensuring the saw is properly grounded and in good working condition.

- Keeping the work area clean and free of debris.

- Never reaching over or behind a running saw blade.

6. How do you maintain and troubleshoot a bridge saw?

- Regularly cleaning and lubricating the saw.

- Checking and replacing worn or damaged parts.

- Troubleshooting common issues, such as blade vibration, motor overheating, or inaccurate cuts.

7. What techniques do you use to optimize cutting efficiency and minimize material waste?

- Optimizing cut paths to reduce unnecessary movement and blade wear.

- Using nesting software to maximize material yield.

- Minimizing the number of cuts required by utilizing multi-axis sawing.

8. How do you handle different materials and their specific cutting requirements?

- Understanding the properties and cutting characteristics of different materials.

- Adjusting cutting parameters accordingly, such as blade speed, feed rate, and blade angle.

- Using specialized blades and techniques for cutting materials such as plastics or non-ferrous metals.

9. What is your experience with using computer-controlled bridge saws?

- Proficient in using CNC bridge saws to execute complex cutting patterns.

- Understanding of CNC programming and G-code language.

- Experience in setting up, calibrating, and troubleshooting CNC bridge saws.

10. How do you stay updated on the latest advancements in bridge saw technology and industry best practices?

- Attending industry workshops and conferences.

- Reading trade publications and technical articles.

- Consulting with equipment manufacturers and suppliers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bridge Saw Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bridge Saw Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Bridge Saw Operator is responsible for operating and maintaining a bridge saw, a specialized machine used to cut and shape large pieces of material, typically in the construction or manufacturing industries. Here are some key job responsibilities:

1. Setup and Operation

Setting up the bridge saw by installing and adjusting the saw blade, workpiece, and other components to ensure precise and efficient cutting.

- Operating the bridge saw to cut materials according to specified dimensions and specifications.

- Monitoring the cutting process and making adjustments to optimize quality and safety.

2. Maintenance and Troubleshooting

Performing routine maintenance and repairs on the bridge saw to ensure optimal performance and prevent breakdowns.

- Inspecting and cleaning the saw blade, bearings, and other components regularly.

- Troubleshooting and resolving any mechanical or electrical issues with the bridge saw.

3. Material Handling

Loading and unloading materials onto the bridge saw using appropriate lifting equipment and techniques.

- Positioning and securing materials on the saw table for accurate cutting.

- Handling and disposing of scrap materials safely and efficiently.

4. Safety and Compliance

Adhering to all safety protocols and regulations related to bridge saw operation.

- Wearing appropriate personal protective equipment (PPE) and following safe operating procedures.

- Maintaining a clean and organized work area to prevent accidents and ensure quality.

Interview Tips

To ace an interview for a Bridge Saw Operator position, here are some tips and hacks:

1. Research the Company and Role

Before the interview, thoroughly research the company, its industry, and the specific role you are applying for. This will help you understand their business needs and tailor your answers accordingly.

- Visit the company website, read industry news, and consult with your network for insights.

- Study the job description carefully and identify the key qualifications and responsibilities required.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are directly relevant to the job requirements. Use specific examples and quantify your accomplishments whenever possible.

- Demonstrate your proficiency in bridge saw operation, including setup, cutting, and maintenance.

- Mention any previous experience in handling heavy materials and operating machinery.

3. Emphasize Safety and Attention to Detail

Bridge saw operation requires a strong focus on safety and attention to detail. Highlight your commitment to adhering to safety protocols and maintaining a clean and organized work environment.

- Describe your experience in following safety procedures and wearing appropriate PPE.

- Provide examples of how you have maintained high levels of accuracy and precision in previous roles.

4. Prepare for Technical Questions

Expect technical questions related to bridge saw operation and maintenance. Be prepared to discuss topics such as:

- Different types of bridge saws and their applications.

- Saw blade selection and maintenance techniques.

- Troubleshooting common bridge saw issues.

5. Practice Your Answers

Practice answering common interview questions aloud to improve your delivery and confidence. Consider using the STAR method to structure your answers (Situation, Task, Action, Result).

- Prepare answers to questions about your experience, skills, safety practices, and technical knowledge.

- Seek feedback from a friend or mentor to refine your responses.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Bridge Saw Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.