Are you gearing up for an interview for a Brim Molder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Brim Molder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

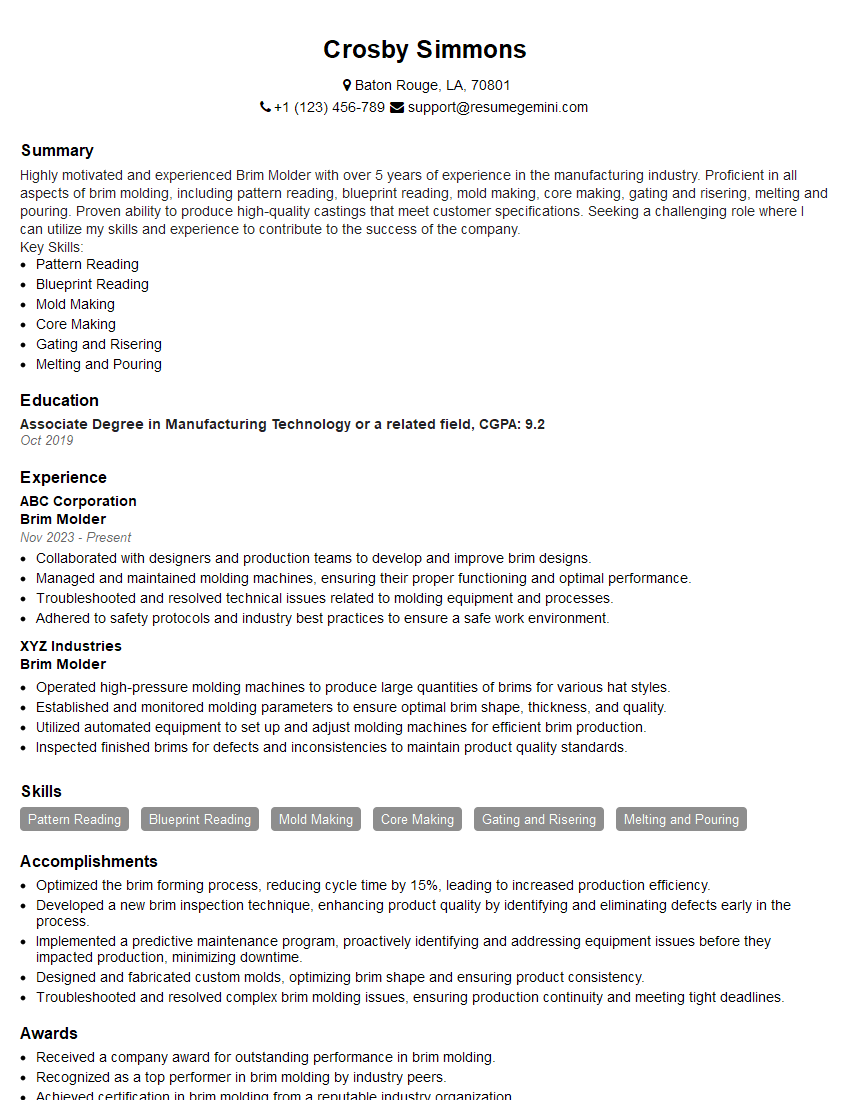

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Brim Molder

1. How do you determine the optimal temperature range for a brim molding process?

- The optimal temperature range for a brim molding process is typically determined by the type of material being molded.

- The material’s melting point and glass transition temperature are important factors to consider.

- Additionally, the molding machine’s capabilities and the desired product quality must also be taken into account.

2. What are the key parameters that affect the dimensional accuracy of brim molded parts?

Factors affecting dimensional accuracy

- Mold temperature

- Material shrinkage

- Injection pressure

- Cooling rate

How to improve dimensional accuracy

- Using high-quality molds with tight tolerances

- Controlling the injection pressure and cooling rate

- Optimizing the mold design to minimize warpage and shrinkage

3. How do you troubleshoot common defects that occur during brim molding, such as voids, flash, and warpage?

- Voids: Caused by entrapped air or insufficient material flow. Can be fixed by increasing injection pressure or optimizing the mold design.

- Flash: Caused by excessive material flow. Can be fixed by reducing injection pressure or improving mold sealing.

- Warpage: Caused by uneven cooling or material shrinkage. Can be fixed by optimizing the cooling system or using materials with lower shrinkage rates.

4. What are the different types of brim molding machines, and how do you select the right one for a particular application?

- Horizontal vs. vertical molding machines

- Manual vs. automatic molding machines

- Single-station vs. multi-station molding machines

- Clamping force, injection pressure, and cycle time

5. How do you maintain and calibrate a brim molding machine to ensure optimal performance?

- Regular cleaning and lubrication

- Calibration of sensors and controllers

- Preventive maintenance to identify and address potential issues

6. What are the safety precautions that should be observed when operating a brim molding machine?

- Wearing appropriate protective gear

- Guarding against moving parts and hot surfaces

- Following proper operating procedures

7. What are the advantages of using brim molding over other molding processes, such as injection molding or extrusion?

- Faster cycle times

- Lower tooling costs

- Ability to mold complex shapes

8. What are the latest trends and developments in brim molding technology?

- Automation and robotics

- Advanced materials and composites

- Sustainability and environmental concerns

9. What is your experience with designing and optimizing brim molding processes?

- Experience with different materials and molding machines

- Use of simulation software to optimize process parameters

- Troubleshooting and problem-solving skills

10. How do you stay up-to-date with the latest advancements in brim molding technology?

- Attending conferences and workshops

- Reading technical journals and articles

- Networking with industry professionals

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Brim Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Brim Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Brim Molders are responsible for creating and maintaining molds used to shape the brims of hats. They work with a variety of materials, including metal, plastic, and wood, to create molds that are accurate and durable. Brim Molders must also be able to operate and maintain the machinery used to create the molds.

1. Create and Maintain Molds

Brim Molders create and maintain molds used to shape the brims of hats. They work with a variety of materials, including metal, plastic, and wood, to create molds that are accurate and durable. Brim Molders must also be able to operate and maintain the machinery used to create the molds.

2. Inspect Molds

Brim Molders inspect molds to ensure that they are accurate and durable. They look for any defects or damage that could affect the quality of the hats produced. Brim Molders also make sure that the molds are properly lubricated and maintained.

3. Operate Machinery

Brim Molders operate machinery used to create molds. They use a variety of machines, including lathes, mills, and presses. Brim Molders must be able to operate these machines safely and efficiently.

4. Maintain Equipment

Brim Molders maintain equipment used to create molds. They clean and lubricate machinery, and make repairs as needed. Brim Molders also keep records of maintenance performed.

Interview Tips

Interviewing for a Brim Molder position can be a daunting task, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the Company

Before your interview, take some time to research the company you’re applying to. This will help you understand their culture, values, and goals. You can also learn about the specific products or services they offer. This information will help you answer questions about the company and show that you’re genuinely interested in the position.

2. Practice Your Answers

Take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during your interview. You can practice answering questions about your experience, skills, and qualifications. You can also practice answering questions about the company and the position you’re applying for.

3. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting. You should also make sure your shoes are clean and polished. A well-put-together appearance will show the interviewer that you’re serious about the position and that you take pride in your work.

4. Be Yourself

It’s important to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be honest and upfront about your experience, skills, and qualifications. The interviewer will appreciate your authenticity and will be more likely to offer you the position if they think you’re a good fit for the company.

Next Step:

Now that you’re armed with the knowledge of Brim Molder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Brim Molder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini