Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Brim-Pouncing Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

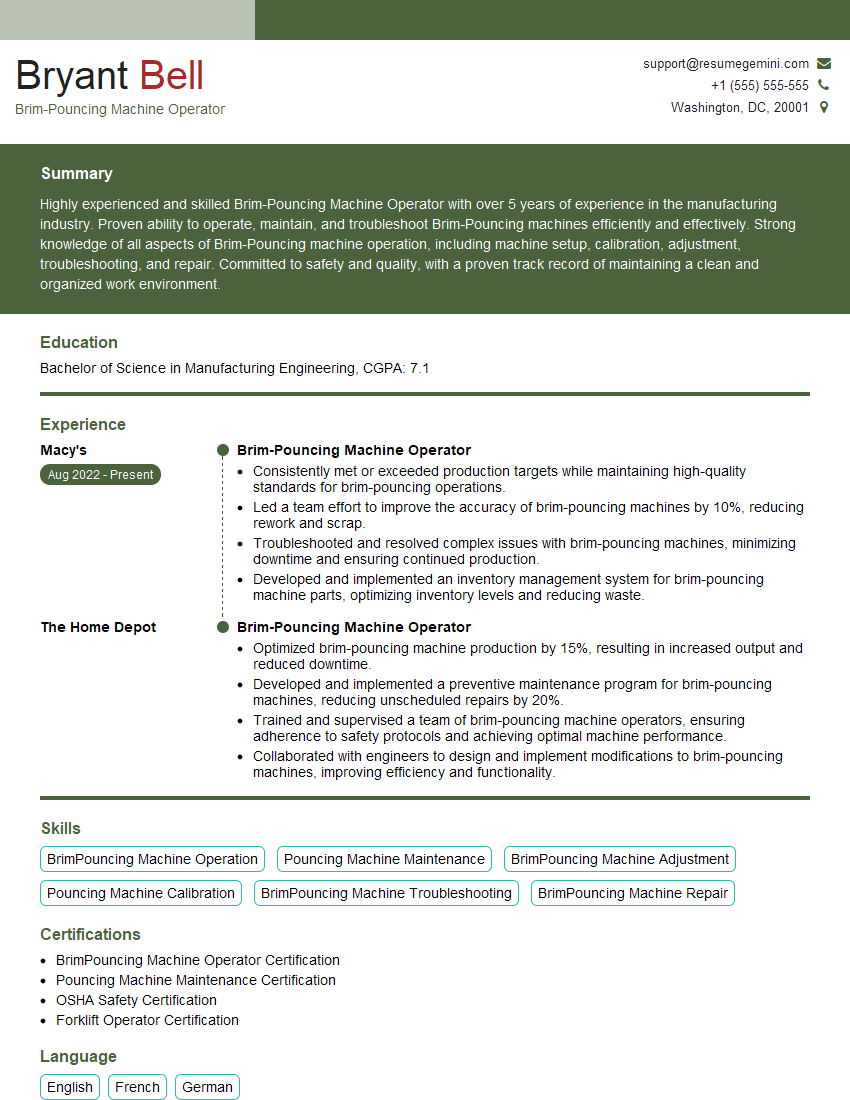

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Brim-Pouncing Machine Operator

1. What are the steps involved in preparing the brim-pouncing machine for operation?

The steps involved in preparing the brim-pouncing machine for operation are as follows:

- Inspect the machine for any damage or wear and tear.

- Clean the machine thoroughly to remove any dirt or debris.

- Lubricate the machine according to the manufacturer’s instructions.

- Install the appropriate dies and punches for the desired operation.

- Set the machine to the correct operating speed and pressure.

- Load the material to be pounced into the machine.

2. How do you troubleshoot a brim-pouncing machine that is not producing quality pounces?

Identifying the Problem

- Check if the dies and punches are sharp and in good condition.

- Examine the material being pounced for any defects or irregularities.

- Inspect the machine’s settings to ensure they are correct.

Resolving the Problem

- Replace or sharpen the dies and punches as needed.

- Adjust the machine’s settings to optimize the pouncing process.

- Clean or replace any components that may be causing the problem.

3. What are the safety precautions that must be followed when operating a brim-pouncing machine?

The following safety precautions must be followed when operating a brim-pouncing machine:

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Keep hands and fingers clear of the moving parts of the machine.

- Do not operate the machine if it is damaged or not properly maintained.

- Be aware of the surroundings and potential hazards.

- Follow all manufacturer’s instructions and safety guidelines.

4. How do you maintain a brim-pouncing machine to ensure optimal performance?

To maintain a brim-pouncing machine for optimal performance, the following steps should be taken:

- Clean the machine regularly to remove any dirt or debris.

- Lubricate the machine according to the manufacturer’s instructions.

- Inspect the dies and punches for wear and tear and replace them as needed.

- Check and adjust the machine’s settings to ensure accuracy.

- Follow all manufacturer’s maintenance guidelines and recommendations.

5. What are the different types of materials that can be pounced using a brim-pouncing machine?

A brim-pouncing machine can pounce a variety of materials, including:

- Leather

- Fabric

- Rubber

- Plastic

- Cork

6. How do you adjust the depth and width of the pounce on a brim-pouncing machine?

The depth and width of the pounce on a brim-pouncing machine can be adjusted by:

- Adjusting the height of the dies and punches.

- Changing the size of the dies and punches.

- Adjusting the pressure applied to the material.

7. What are the common defects that can occur during brim-pouncing and how do you prevent them?

Common defects that can occur during brim-pouncing and their prevention methods include:

- Uneven pounces: caused by uneven pressure or misaligned dies. Prevention: Ensure proper alignment and even pressure distribution.

- Tearing of material: caused by excessive pressure or dull dies. Prevention: Use sharp dies and adjust the pressure accordingly.

- Skipping or incomplete pounces: caused by worn-out dies or incorrect settings. Prevention: Replace dies regularly and check settings for accuracy.

8. How do you calibrate a brim-pouncing machine to ensure accuracy and precision?

Calibrating a brim-pouncing machine involves the following steps:

- Set a reference point on the machine.

- Use a precision measuring device to measure the depth and width of the pounce.

- Adjust the machine settings until the desired dimensions are achieved.

- Repeat the measurements to ensure accuracy and precision.

9. What are the different applications of brim-pouncing in various industries?

Brim-pouncing has various applications across industries, including:

- Shoemaking: Creating decorative patterns on leather shoe brims.

- Hat manufacturing: Shaping and stiffening hat brims.

- Belt production: Embossing designs on leather belts.

- Bookbinding: Decorating book covers with intricate patterns.

10. How do you stay updated with the latest advancements and best practices in brim-pouncing technology?

To stay updated with the latest advancements and best practices in brim-pouncing technology, I actively engage in the following activities:

- Attend industry workshops and conferences.

- Read technical articles and research papers.

- Network with other brim-pouncing professionals.

- Explore online forums and discussion groups.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Brim-Pouncing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Brim-Pouncing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Brim-Pouncing Machine Operators are responsible for the efficient operation and maintenance of brim-pouncing machines used in the manufacturing of hats and other headwear. Their primary duties include:

1. Machine Operation

Setting up and operating brim-pouncing machines to shape and finish hat brims.

- Loading hat brims into the machine.

- Adjusting machine settings to achieve desired shape and finish.

- Monitoring machine operation and making necessary adjustments.

2. Quality Control

Inspecting finished hat brims for defects and ensuring they meet quality standards.

- Identifying and correcting any irregularities in shape, size, or texture.

- Rejecting brims that do not meet specifications.

3. Maintenance and Repair

Performing routine maintenance and repairs on brim-pouncing machines.

- Lubricating and cleaning machine components.

- Inspecting and replacing worn or damaged parts.

- Troubleshooting and resolving machine malfunctions.

4. Production Optimization

Collaborating with supervisors and other team members to identify and implement ways to improve production efficiency and quality.

- Analyzing machine performance data.

- Suggesting improvements to machine settings or operating procedures.

Interview Tips

To ace an interview for a Brim-Pouncing Machine Operator position, candidates should prepare thoroughly and demonstrate their knowledge and skills in the following areas:

1. Technical Skills

Candidates should highlight their proficiency in operating and maintaining brim-pouncing machines.

- Describe specific experience in setting up and operating brim-pouncing machines.

- Provide examples of troubleshooting and resolving machine malfunctions.

- Explain how they ensure the production of high-quality hat brims.

2. Attention to Detail

Candidates should emphasize their ability to pay close attention to detail and identify defects in hat brims.

- Discuss their experience in inspecting finished products for defects.

- Provide examples of situations where they identified and corrected quality issues.

- Explain how they maintain a clean and organized work area.

3. Communication and Teamwork

Candidates should demonstrate strong communication and teamwork skills.

- Describe experiences collaborating with supervisors and team members.

- Provide examples of how they communicated production issues and suggested solutions.

- Explain how they maintain a positive and cooperative attitude in a team environment.

4. Problem-Solving

Candidates should showcase their ability to solve problems and make decisions.

- Discuss situations where they identified and resolved production problems.

- Provide examples of how they analyzed data and made recommendations for improvements.

- Explain how they handle unexpected challenges and find creative solutions.

Next Step:

Now that you’re armed with the knowledge of Brim-Pouncing Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Brim-Pouncing Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini