Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Brine Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

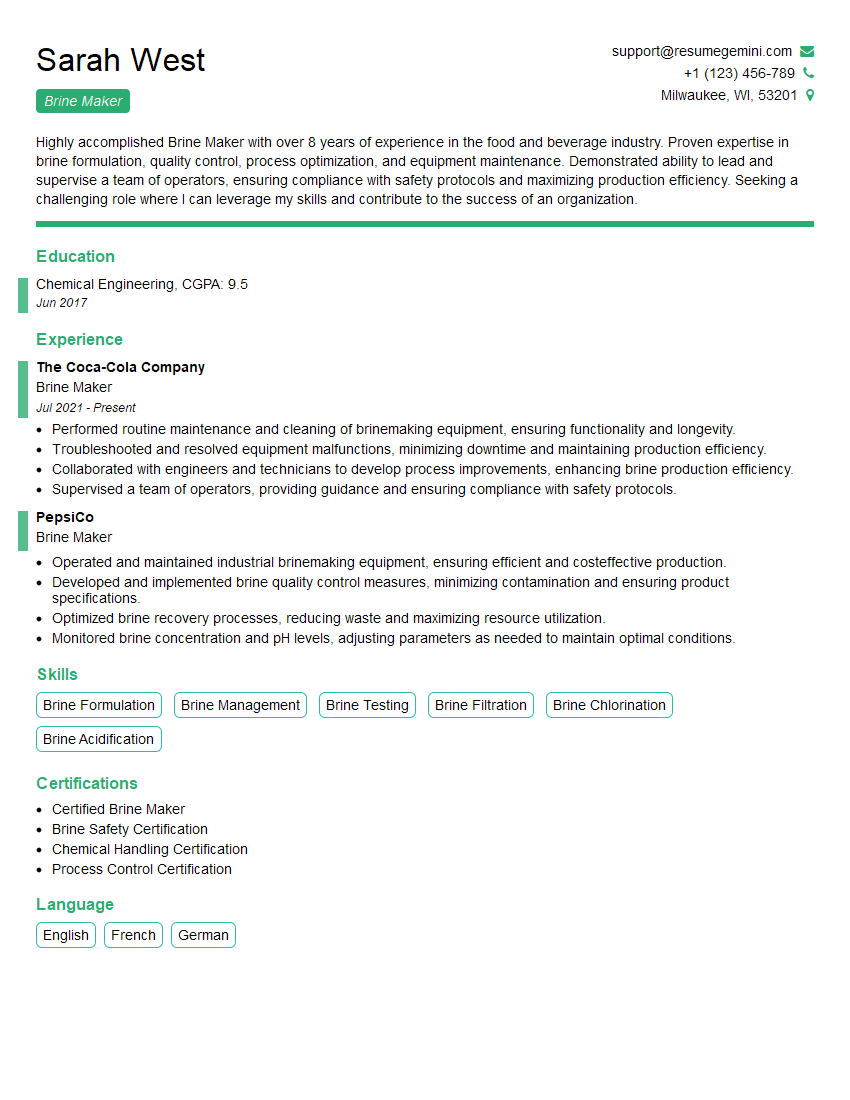

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Brine Maker

1. Describe the process of making brine and the equipment involved.

The process of making brine involves dissolving salt in water to create a saturated solution. The salt dissolves into ions, such as sodium and chloride, which create an electrolyte solution. The equipment required for making brine typically includes a brine maker, a salt dissolver, a storage tank, and a pump. The brine maker is used to dissolve the salt into the water, the salt dissolver is used to break up any clumps of salt, the storage tank is used to store the brine, and the pump is used to circulate the brine.

2. What are the different types of brine and their applications?

There are two main types of brine: saturated brine and unsaturated brine. Saturated brine is a solution in which no more salt can be dissolved at a given temperature. Unsaturated brine is a solution in which more salt can be dissolved. Saturated brine is typically used in food preservation, such as in the production of pickles and sauerkraut. Unsaturated brine is typically used in industrial applications, such as in the production of chemicals and textiles.

3. What are the factors that affect the solubility of salt in water?

- Temperature

- Pressure

- Salt type

- Water purity

4. How do you control the concentration of brine?

- Using a hydrometer

- Using a refractometer

- Using a conductivity meter

5. What are the safety precautions that should be taken when working with brine?

- Wear appropriate protective clothing, such as gloves and eye protection.

- Do not ingest brine.

- Do not allow brine to come into contact with skin or eyes.

- If brine does come into contact with skin or eyes, rinse immediately with plenty of water.

- Store brine in a safe and secure location.

6. What is the role of a brine maker in a food processing plant?

- Operate and maintain brine making equipment.

- Monitor and control the concentration of brine.

- Ensure that brine is safe and suitable for use in food processing.

- Troubleshoot and resolve problems with brine making equipment.

7. What are the qualifications and experience required to become a brine maker?

- High school diploma or equivalent.

- 1-2 years of experience in a food processing environment.

- Knowledge of brine making equipment and processes.

- Ability to work independently and as part of a team.

- Strong attention to detail.

8. What are the challenges of working as a brine maker?

- Working with hazardous chemicals.

- Maintaining a safe and clean work environment.

- Ensuring the quality of brine.

- Meeting production targets.

- Working in a fast-paced environment.

9. What are the rewards of working as a brine maker?

- Job security.

- Competitive salary and benefits.

- Opportunities for advancement.

- Making a valuable contribution to the food industry.

- Working in a team environment.

10. What are your career goals?

I am looking to obtain a position as a brine maker in a food processing plant. I am confident that my skills and experience would be a valuable asset to your company. I am eager to learn and grow in this role, and I am committed to producing high-quality brine that meets the needs of your customers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Brine Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Brine Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Brine Maker plays a crucial role in the food industry. Their primary responsibility involves preparing and maintaining brines, which are important ingredients used in preserving and flavoring various food products.

1. Preparation and Maintenance of Brines

Brine Makers are responsible for preparing brines by carefully measuring and mixing ingredients such as salt, sugar, water, and other additives, ensuring precise adherence to specified formulations.

- Measuring and mixing ingredients accurately to create brines with the desired concentration and flavor profile.

- Maintaining the quality and consistency of brines by regularly monitoring their pH levels, salt content, and other parameters.

2. Equipment Operation and Maintenance

Brine Makers operate and maintain various equipment used in the preparation and handling of brines.

- Operating brine mixers, pumps, and other equipment to prepare and transfer brines efficiently.

- Cleaning and maintaining equipment to ensure proper functionality and prevent contamination.

3. Quality Assurance and Control

Brine Makers play a vital role in ensuring the quality and safety of brines.

- Conducting regular quality checks on brines to verify their concentration and flavor, ensuring compliance with established standards.

- Maintaining detailed records of brine preparation, monitoring, and quality checks for traceability and compliance.

4. Health and Safety Compliance

Brine Makers prioritize maintaining a safe and hygienic work environment.

- Adhering to established safety protocols and wearing appropriate personal protective equipment.

- Following proper handling and disposal procedures for chemicals and waste materials.

Interview Tips

Preparing for a Brine Maker interview requires careful consideration of the job responsibilities and industry knowledge. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Demonstrate your interest and understanding of the company’s products, processes, and the overall food industry by conducting thorough research before the interview.

- Visit the company’s website to gather information about their brining operations and industry standing.

- Read industry publications and articles to stay abreast of the latest trends and best practices in brine preparation.

2. Highlight Relevant Experience and Skills

Emphasize your past experience in brine preparation and maintenance, ensuring you provide specific examples of your responsibilities and accomplishments.

- Quantify your experience by providing specific metrics or outcomes, such as the volume of brines prepared or the accuracy of brine concentrations maintained.

- Showcase your proficiency in operating and maintaining brine-related equipment, including any specialized knowledge or certifications.

3. Demonstrate Quality Assurance Skills

Highlight your understanding and experience in quality assurance and control procedures related to brine preparation.

- Explain your methods for monitoring and maintaining brine quality, including the use of testing equipment and documentation procedures.

- Emphasize your commitment to food safety and your ability to ensure that brines meet regulatory standards.

4. Prepare for Technical Questions

Anticipate technical questions related to brine chemistry, equipment operation, and troubleshooting. Be ready to discuss:

- The different types of brines and their applications in the food industry.

- The factors that affect brine concentration and stability.

- Common problems encountered in brine preparation and maintenance, and your strategies for resolving them.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Brine Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!