Feeling lost in a sea of interview questions? Landed that dream interview for Brine Tank Separator Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Brine Tank Separator Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

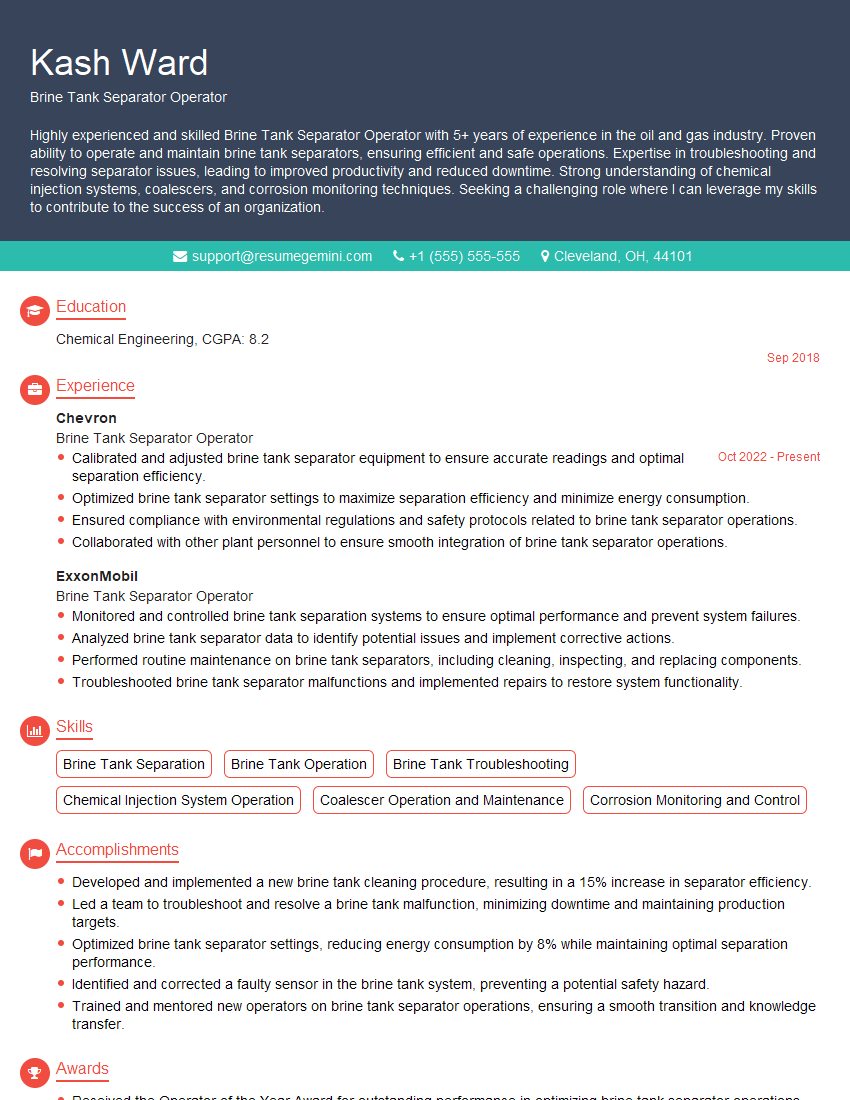

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Brine Tank Separator Operator

1. Explain the process of brine tank separation in detail?

The brine tank separation process involves the following steps:

- Raw water is pumped into the brine tank.

- Chemicals are added to the water to cause the impurities to coagulate and form flocs.

- The flocs are allowed to settle to the bottom of the tank.

- The clear water is drawn off from the top of the tank.

- The sludge is removed from the bottom of the tank.

2. What are the key factors that affect the efficiency of brine tank separation?

Factors affecting efficiency

- The type of coagulant used

- The dosage of coagulant

- The pH of the water

- The temperature of the water

- The concentration of impurities in the water

3. What are the different types of coagulants used in brine tank separation?

The most common types of coagulants used in brine tank separation are:

- Aluminum sulfate

- Ferric chloride

- Polyaluminum chloride

- Sodium aluminate

4. How do you determine the optimum dosage of coagulant for a particular water source?

The optimum dosage of coagulant is determined by conducting jar tests.

- Different dosages of coagulant are added to samples of the water.

- The samples are allowed to settle.

- The clarity of the supernatant is measured.

- The optimum dosage is the dosage that produces the clearest supernatant.

5. What are the common problems that can occur in brine tank separation and how do you troubleshoot them?

Common problems that can occur in brine tank separation include:

- Carryover of flocs into the clear water

- Settling of flocs to the bottom of the tank

- Formation of sludge

- Corrosion of the tank

Troubleshooting involves identifying the cause of the problem and implementing corrective actions.

6. What are the safety precautions that must be observed when operating a brine tank separator?

Safety precautions that must be observed when operating a brine tank separator include:

- Wearing appropriate personal protective equipment

- Following safe operating procedures

- Being aware of the hazards of the chemicals used

- Knowing what to do in case of an emergency

7. What are the maintenance tasks that are required for a brine tank separator?

Maintenance tasks that are required for a brine tank separator include:

- Cleaning the tank

- Inspecting the tank for damage

- Calibrating the instruments

- Replacing worn parts

8. How do you ensure that the brine tank separator is operating efficiently?

To ensure that the brine tank separator is operating efficiently, the following steps can be taken:

- Monitoring the performance of the separator

- Making adjustments to the operating parameters as needed

- Conducting regular maintenance

9. What are the environmental regulations that apply to the operation of a brine tank separator?

Environmental regulations that apply to the operation of a brine tank separator include:

- The Clean Water Act

- The Resource Conservation and Recovery Act

- The Toxic Substances Control Act

10. What is the role of a brine tank separator operator?

The role of a brine tank separator operator is to ensure that the brine tank separator is operating efficiently and in compliance with all applicable environmental regulations.

- Operate the brine tank separator

- Monitor the performance of the separator

- Make adjustments to the operating parameters as needed

- Conduct regular maintenance

- Follow all applicable environmental regulations

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Brine Tank Separator Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Brine Tank Separator Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Brine Tank Separator Operator is responsible for the safe and efficient operation of brine tank separators, which are used to remove salt and other impurities from brine.

1. Operating and Monitoring Equipment

Operate and monitor brine tank separators to ensure proper operation and efficiency.

- Start, stop, and adjust equipment as needed.

- Monitor operating parameters such as flow rates, pressure, and temperature.

2. Maintaining Equipment

Perform routine maintenance and repairs on brine tank separators to ensure optimal performance.

- Inspect equipment for wear and tear.

- Clean and lubricate equipment as needed.

3. Sampling and Testing

Conduct sampling and testing of brine to monitor its quality and ensure compliance with regulations.

- Collect samples of brine for testing.

- Analyze samples to determine salt content and other impurities.

4. Safety and Compliance

Follow safety protocols and comply with environmental regulations related to brine tank separator operations.

- Wear appropriate personal protective equipment.

- Maintain a clean and safe work area.

Interview Tips

Preparing for an interview for a Brine Tank Separator Operator position requires thorough research and practice. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s operations, industry trends, and the specific requirements of the Brine Tank Separator Operator role.

2. Highlight Relevant Experience and Skills

Emphasize your experience in operating and maintaining brine tank separators, as well as your knowledge of sampling and testing procedures. Quantify your accomplishments whenever possible.

3. Demonstrate Safety Consciousness

Stress your commitment to safety and compliance. Discuss your understanding of industry regulations and your experience in maintaining a safe work environment.

4. Prepare for Technical Questions

Expect questions about the operation, maintenance, and troubleshooting of brine tank separators. Be prepared to explain technical concepts clearly and concisely.

5. Practice Your Answers

Rehearse your answers to common interview questions. This will help you feel confident and articulate during the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Brine Tank Separator Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!