Are you gearing up for a career in Briquette Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Briquette Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

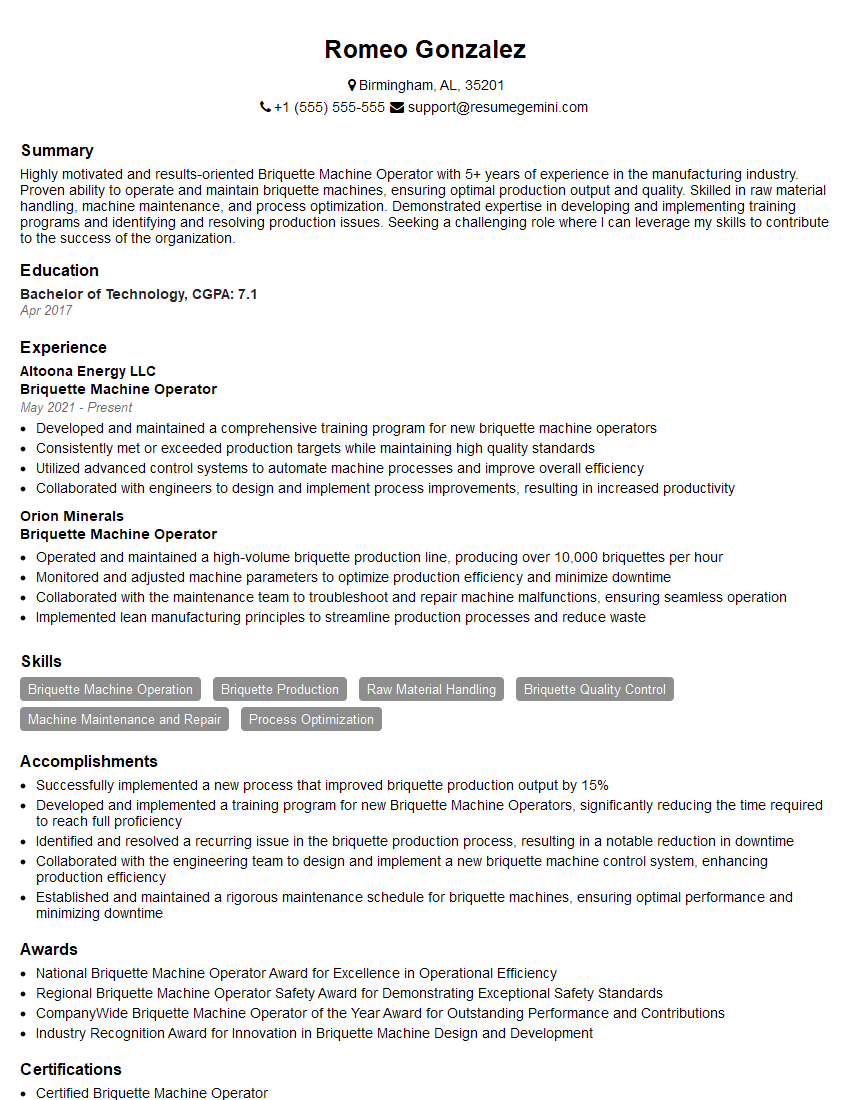

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Briquette Machine Operator

1. Describe the key steps involved in operating a briquette machine.

In a nutshell, operating a briquette machine involves:

- Preparing the raw materials, like crushing and drying them to the appropriate size and moisture content.

- Loading the raw materials into the machine’s hopper.

- Controlling the machine’s temperature and pressure settings based on the desired briquette properties.

- Monitoring the machine’s performance and making adjustments as needed to ensure the briquettes meet the desired specifications.

- Collecting and storing the finished briquettes for further processing or use.

2. How do you determine the correct temperature and pressure settings for different types of briquettes?

The ideal temperature and pressure settings depend on various factors such as:

Material Characteristics

- The type and composition of the raw materials

- Their moisture content and particle size

Desired Briquette Properties

- The required density and hardness of the briquettes

- Their intended use or application

To determine the optimal settings, I rely on my knowledge and experience with different materials and briquette types.

3. What are the common problems that can occur during briquetting, and how do you troubleshoot them?

Sure! common issues in briquetting include:

- Insufficient bonding: This can occur due to improper temperature, pressure, or moisture content. I adjust the machine settings accordingly and ensure the raw materials meet the required specifications.

- Overheating: Excessive temperature can lead to material degradation. I closely monitor the temperature and make necessary adjustments to prevent overheating.

- Blockages: Foreign objects or excessive moisture can cause blockages. I regularly clean and maintain the machine to prevent such issues.

- Equipment malfunction: I am trained to identify and troubleshoot mechanical or electrical problems. I conduct regular maintenance and promptly address any issues to minimize downtime.

4. How do you ensure the safety and quality of briquette production?

Safety and quality are paramount!

- Safety: I strictly adhere to all safety protocols, wear appropriate protective gear, and ensure the work area is free from hazards.

- Quality: I conduct regular inspections of the raw materials and finished briquettes. I maintain detailed production records and implement quality control measures to ensure the briquettes meet the desired specifications.

5. What are the key performance indicators (KPIs) for a briquette machine operator, and how do you monitor them?

KPIs help me gauge my performance:

- Production Output: I track the quantity of briquettes produced per hour or shift.

- Briquette Quality: I monitor the density, hardness, and moisture content of the briquettes to ensure they meet the required standards.

- Machine Uptime: I record the machine’s operating time and identify areas for improvement to minimize downtime.

- Resource Consumption: I monitor the consumption of raw materials, energy, and consumables to optimize efficiency.

6. How do you stay updated on the latest advancements in briquetting technology?

To keep up with the latest:

- Attend industry events and conferences: I network with experts and learn about new technologies.

- Read trade publications and technical journals: I stay informed about industry trends and best practices.

- Seek training opportunities: I participate in workshops and courses to enhance my knowledge and skills.

7. Describe how you maintain and calibrate the briquette machine to ensure optimal performance.

Regular maintenance is crucial!

- Daily Checks: I inspect the machine for any visible issues, lubricate moving parts, and clean the components.

- Scheduled Maintenance: I follow a preventive maintenance schedule to replace worn parts, adjust clearances, and calibrate sensors.

- Calibration: I use calibrated tools and follow established procedures to ensure the machine operates within specified tolerances.

8. What is the role of a briquette machine operator in the overall production process?

My role is integral:

- Ensuring a steady supply of briquettes: I operate the machine efficiently to meet production targets.

- Maintaining product quality: I monitor and control the briquette properties to meet customer specifications.

- Optimizing machine performance: I identify and address any issues to minimize downtime and maximize productivity.

- Collaborating with other team members: I coordinate with raw material suppliers, quality control personnel, and maintenance technicians to ensure smooth operation.

9. How do you handle situations where the briquette machine malfunctions or breaks down?

In case of a malfunction:

- Immediate Response: I promptly identify the issue and take steps to minimize downtime.

- Troubleshooting: I use my technical knowledge and experience to diagnose the problem.

- Repairs: If possible, I perform minor repairs myself. For major issues, I contact the maintenance team.

- Communication: I keep my supervisor and team members informed about the situation and estimated repair time.

10. What are your strengths and weaknesses relevant to this role?

My strengths include:

- Technical Expertise: I have a deep understanding of briquette machine operation, maintenance, and troubleshooting.

- Quality Focus: I am committed to producing high-quality briquettes that meet customer specifications.

- Problem-Solving Abilities: I am adept at identifying and resolving issues to minimize downtime.

- Team Player: I work effectively with colleagues to ensure smooth production.

As for weaknesses, I am always striving to improve:

- Limited Experience with Certain Raw Materials: I am eager to expand my experience with different materials.

- Time Management: I am working on improving my time management skills to optimize productivity.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Briquette Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Briquette Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Briquette Machine Operators play a vital role in ensuring the smooth operation of briquette production facilities. Their key job responsibilities include:

1. Operating and maintaining briquette machines

Briquette Machine Operators are responsible for operating and maintaining briquette machines, which convert loose materials such as sawdust, paper, or coal into densely packed briquettes. They must ensure that the machines are properly calibrated and adjusted to produce briquettes that meet the required specifications.

2. Monitoring production processes

Operators closely monitor the production process to ensure that the briquettes are produced efficiently and meet quality standards. They also make adjustments to the machine settings as needed to optimize production.

3. Troubleshooting and resolving issues

When problems arise with the briquette machine or production process, Operators are responsible for troubleshooting and resolving the issues. They must have a thorough understanding of the machine’s mechanics and the production process to identify and fix problems quickly and efficiently.

4. Maintaining a clean and safe work area

Operators are responsible for maintaining a clean and safe work area to prevent accidents and ensure the smooth operation of the production process. They must follow all safety protocols and procedures while working with the machines.

Interview Tips

To ace an interview for a Briquette Machine Operator position, candidates should:

1. Research the company and the position

Before the interview, candidates should thoroughly research the company and the specific position they are applying for. This will help them understand the company’s culture, values, and expectations for the role.

2. Prepare answers to common interview questions

Candidates should prepare answers to common interview questions, such as “Tell me about yourself,” “Why are you interested in this position?,” and “What are your strengths and weaknesses?” They should practice their answers to ensure they are clear, concise, and relevant to the job.

3. Highlight relevant skills and experience

Candidates should highlight their relevant skills and experience that make them a suitable candidate for the position. They should focus on transferable skills, such as problem-solving, troubleshooting, and attention to detail, as well as any specific knowledge or experience related to operating briquette machines.

4. Be prepared to discuss safety protocols

As safety is paramount in this role, candidates should be prepared to discuss their understanding of safety protocols and procedures. They should demonstrate that they are familiar with the potential hazards associated with operating briquette machines and the steps they take to mitigate risks.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Briquette Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!