Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Briquette Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

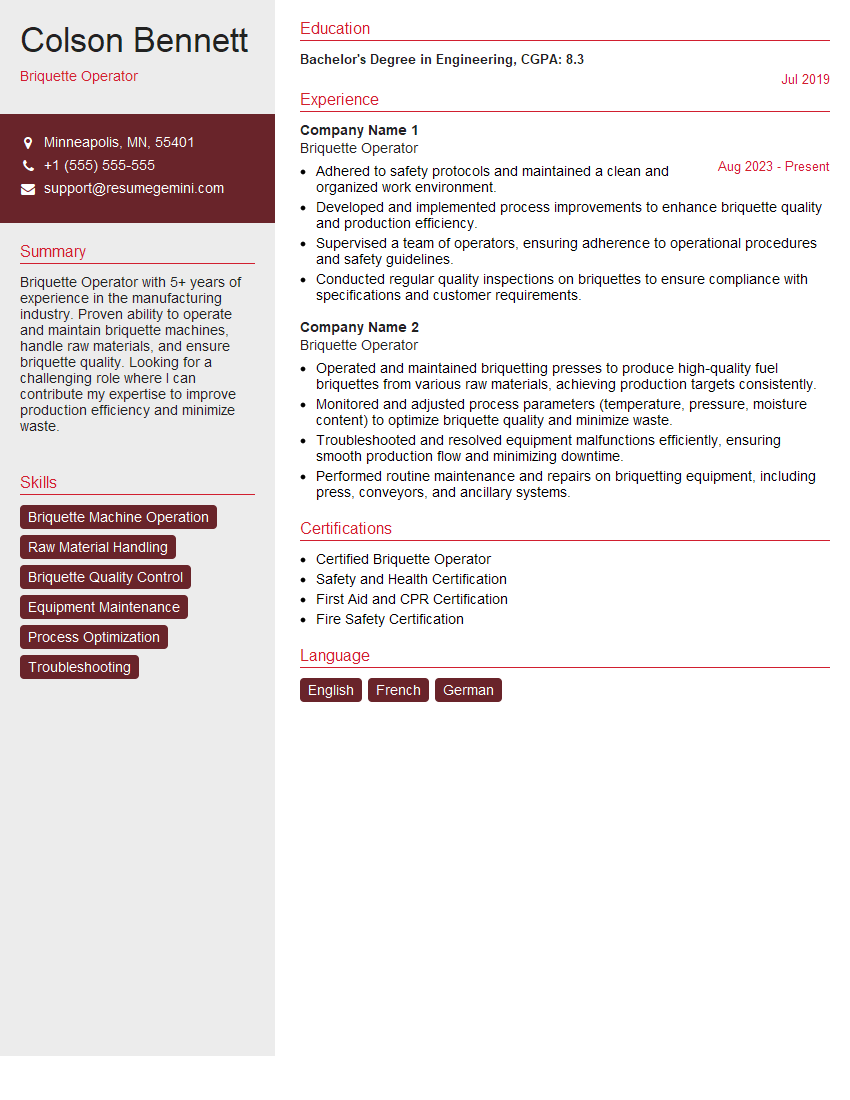

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Briquette Operator

1. Describe your understanding of the briquetting process?

The briquetting process involves compacting loose biomass materials, such as sawdust, agricultural residues, or coal dust, into dense briquettes. These briquettes are typically used as a solid fuel source for various applications.

- The process begins with preparing the biomass material by removing impurities and ensuring proper moisture content.

- The prepared material is then fed into a briquetting machine, where it is subjected to high pressure and heat, causing the particles to bind together and form briquettes.

2. What are the critical parameters to consider when operating a briquette machine?

Raw Material Quality

- Moisture content

- Particle size

- Density

Machine Settings

- Pressure

- Temperature

- Die size

3. How do you troubleshoot common problems encountered in briquette production?

Common problems encountered in briquette production include:

- Low briquette density: Adjust machine pressure, check raw material moisture content, or consider using a different binder.

- Cracking or crumbling briquettes: Optimize moisture content, reduce pressure, or adjust die size.

- Blockages in the machine: Clean the machine regularly, check for foreign objects in the raw material, or adjust the feed rate.

4. What maintenance procedures are essential for ensuring the longevity of a briquette machine?

Essential maintenance procedures for briquette machines include:

- Regular cleaning to remove dust and debris.

- Lubrication of moving parts.

- Inspection and replacement of worn or damaged components.

- Monitoring of temperature and pressure levels.

5. Explain the role of binders in briquette production.

Binders are substances added to the raw material to enhance the bonding between particles during briquetting. They help increase briquette strength and durability.

- Common binders include starch, molasses, lignin, and synthetic polymers.

- The type and amount of binder used depend on the raw material characteristics and desired briquette properties.

6. How do you ensure the quality of briquettes produced?

To ensure briquette quality, regular monitoring and testing are necessary:

- Visual inspection: Check for cracks, crumbling, and uniform shape.

- Density measurement: Determine the compactness and strength of briquettes.

- Calorific value analysis: Assess the energy content of briquettes.

- Moisture content determination: Ensure compliance with moisture specifications.

7. What safety precautions should be taken when operating a briquette machine?

Safety precautions for briquette machine operation include:

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and earplugs.

- Follow lockout/tagout procedures before performing maintenance or repairs.

- Ensure proper machine grounding to prevent electrical hazards.

- Avoid loose clothing or jewelry that could get caught in moving parts.

8. How do you optimize the efficiency of a briquette production line?

To optimize efficiency, consider the following measures:

- Optimize raw material preparation to ensure consistent feedstock quality.

- Fine-tune machine settings based on raw material characteristics.

- Minimize downtime through regular maintenance and preventative measures.

- Implement process automation to reduce manual labor.

9. What knowledge and skills are essential for a successful Briquette Operator?

- Understanding of briquetting principles.

- Expertise in operating and maintaining briquette machines.

- Problem-solving and troubleshooting abilities.

- Attention to detail and quality control.

- Physical stamina and ability to work in a production environment.

10. How do you stay updated with the latest advancements in briquette technology?

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Network with other briquette operators and professionals.

- Participate in training programs offered by equipment manufacturers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Briquette Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Briquette Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Briquette Operators are responsible for overseeing the production of briquettes from raw materials such as coal or biomass. They operate and maintain briquetting machinery, monitor production processes, and ensure that the final product meets quality standards.

1. Operating Briquetting Machinery

Briquette Operators are responsible for the operation of briquetting machines, which compress raw materials into briquettes. They must be able to set up, adjust, and operate these machines safely and efficiently.

- Set up and operate briquetting machines according to established procedures.

- Monitor machine operations and make necessary adjustments to maintain production efficiency.

- Troubleshoot and resolve any operational issues that may arise.

2. Monitoring Production Processes

Briquette Operators are responsible for monitoring the production process to ensure that the briquettes are produced to the desired specifications. They must be able to identify and correct any deviations from the standard operating procedures.

- Monitor production processes to ensure that they are running smoothly.

- Identify and correct any deviations from the standard operating procedures.

- Make adjustments to the production process as needed to optimize efficiency.

3. Ensuring Product Quality

Briquette Operators are responsible for ensuring that the final product meets the required quality standards. They must be able to inspect the briquettes for defects, and take corrective action if necessary.

- Inspect briquettes for defects, such as cracks or broken edges.

- Take corrective action if any defects are found.

- Maintain records of production and quality control.

4. Maintaining a Safe Work Environment

Briquette Operators are responsible for maintaining a safe work environment in the briquetting plant. They must be familiar with all safety regulations and procedures, and follow them at all times.

- Follow all safety regulations and procedures.

- Identify and report any potential hazards.

- Take appropriate actions to mitigate any risks.

Interview Tips

Preparing for a job interview can be daunting, but it’s important to remember that it’s also an opportunity to showcase your skills and experience. Here are a few tips to help you ace your interview for a Briquette Operator position:

1. Research the Company and the Position

Before you go to the interview, take some time to research the company and the specific position you’re applying for. This will help you understand the company’s culture, values, and what they’re looking for in a candidate.

- Visit the company’s website to learn about their history, products or services, and recent news.

- Read industry publications and articles to stay up-to-date on the latest trends and technologies.

- Network with people who work in the industry or at the company you’re applying to.

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” or “Why are you interested in this position?” It’s a good idea to practice your answers to these questions ahead of time so that you can deliver them confidently and concisely.

- Use the STAR method to answer behavioral questions.

- Be specific and provide examples to support your answers.

- Keep your answers concise and to the point.

3. Dress Professionally and Be on Time

First impressions matter, so it’s important to dress professionally and arrive on time for your interview. This shows the interviewer that you’re serious about the position and that you respect their time.

- Wear a suit or business casual attire.

- Make sure your clothes are clean and pressed.

- Arrive for your interview on time.

4. Be Yourself and Be Enthusiastic

It’s important to be yourself during your interview and to show the interviewer your enthusiasm for the position. This will help you make a connection with the interviewer and leave a lasting impression.

- Be genuine and authentic.

- Show your enthusiasm for the position.

- Ask questions about the company and the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Briquette Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!