Are you gearing up for an interview for a Briquetter Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Briquetter Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

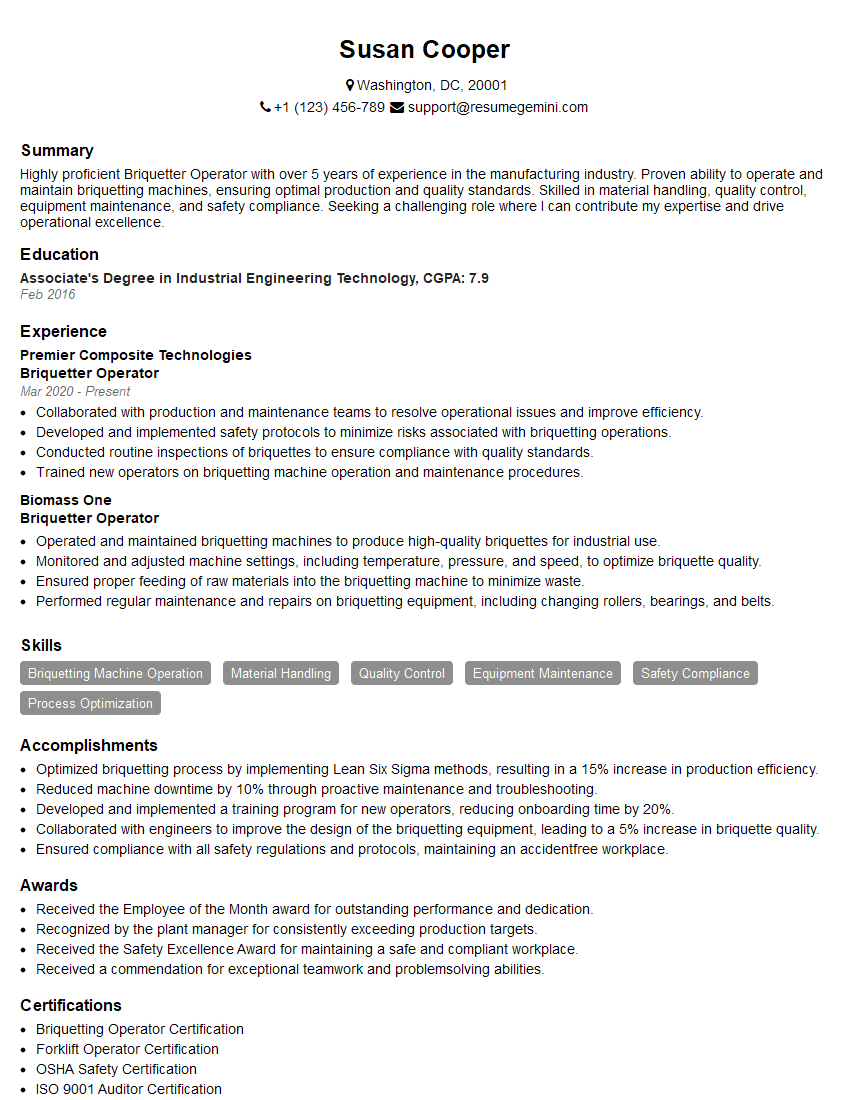

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Briquetter Operator

1. What is the purpose of a briquetting machine?

- answer: A briquetting machine is used to compress loose materials, such as sawdust, wood chips, or coal dust, into compact and uniform briquettes.

2. What are the different types of briquetting machines?

answer: There are two main types of briquetting machines: mechanical and hydraulic.

Mechanical briquetting machines

- Use a mechanical press to compress the material.

- Are typically used for low-volume production.

Hydraulic briquetting machines

- Use a hydraulic press to compress the material.

- Are typically used for high-volume production.

3. What are the key factors that affect the quality of briquettes?

- answer: The key factors that affect the quality of briquettes include:

- The type of material being briquetted.

- The moisture content of the material.

- The pressure applied during briquetting.

- The temperature of the material during briquetting.

- The cooling rate of the briquettes.

4. How do you troubleshoot a briquetting machine?

- answer: To troubleshoot a briquetting machine, you can follow these steps:

- Check the power supply to the machine.

- Check the hydraulic system for leaks.

- Check the mechanical components for wear and tear.

- Check the material being briquetted for consistency.

- Check the briquettes for quality.

5. What are the safety precautions that must be taken when operating a briquetting machine?

- answer: When operating a briquetting machine, you must take the following safety precautions:

- Wear appropriate safety gear, such as gloves, safety glasses, and a hard hat.

- Keep your hands and feet away from moving parts.

- Do not operate the machine if it is not in good working order.

- Follow the manufacturer’s instructions for operating the machine.

6. What is the role of a briquetter operator?

- answer: The role of a briquetter operator is to operate and maintain a briquetting machine to produce briquettes from loose materials.

7. What are the key skills and qualifications required for a briquetter operator?

- answer: The key skills and qualifications required for a briquetter operator include:

- Experience in operating and maintaining briquetting machines.

- Knowledge of the different types of briquetting machines and the materials that can be briquetted.

- Understanding of the factors that affect the quality of briquettes.

- Ability to troubleshoot and repair briquetting machines.

- Strong attention to detail.

- Ability to work independently and as part of a team.

8. What is the average salary for a briquetter operator?

- answer: The average salary for a briquetter operator varies depending on experience, location, and company size. According to Indeed, the average salary for a briquetter operator in the United States is $45,000 per year.

9. What are the career prospects for a briquetter operator?

- answer: The career prospects for a briquetter operator are good. With experience, briquetter operators can move into supervisory or management roles. They can also start their own briquetting business.

10. What is the future of the briquetting industry?

- answer: The future of the briquetting industry is bright. The increasing demand for renewable energy sources is driving the growth of the briquetting industry. Briquettes are a sustainable and environmentally friendly alternative to fossil fuels.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Briquetter Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Briquetter Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Briquetter Operators play a crucial role in the production process, ensuring the efficient operation and maintenance of briquetting machines. Their key responsibilities include:

1. Machine Operation and Monitoring

Operate briquetting machines to compress and form materials into briquettes.

- Monitor machine performance, ensuring smooth operation and timely adjustments.

- Control material flow, ensuring consistent briquette size and quality.

2. Maintenance and Troubleshooting

Perform routine maintenance tasks to ensure optimal machine performance.

- Inspect and clean machines regularly, identifying and addressing potential issues.

- Troubleshoot and resolve operational problems, minimizing downtime.

3. Quality Control

Monitor and ensure the quality of briquettes produced.

- Inspect briquettes for size, shape, and density.

- Adjust machine settings or materials to ensure compliance with specifications.

4. Safety and Compliance

Ensure compliance with safety regulations and procedures.

- Operate machines safely, following established guidelines.

- Maintain a clean and organized work area, minimizing hazards.

Interview Tips

Ace the Briquetter Operator interview by following these tips:

1. Research the Company and Role

Gain insight into the company’s values and the specific requirements of the role.

- Visit the company website and LinkedIn page.

- Review the job description and highlight your relevant skills and experience.

2. Practice Your Answers

Prepare responses to common interview questions, emphasizing your strengths and qualifications.

- Anticipate questions about your machine operation skills, troubleshooting abilities, and quality control measures.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers, providing specific examples of your accomplishments.

3. Demonstrate Technical Knowledge

Showcase your understanding of briquetting machines and processes.

- Be familiar with different types of briquetting machines and their applications.

- Explain the basic principles of briquetting, including material preparation and forming methods.

4. Highlight Your Safety Mindset

Emphasize your commitment to safety and compliance.

- Describe your adherence to established safety protocols and procedures.

- Provide examples of how you have identified and addressed potential hazards in the workplace.

5. Ask Thoughtful Questions

Demonstrate your interest and engagement by asking insightful questions.

- Inquire about the company’s sustainability practices and how they align with your values.

- Ask about opportunities for professional development and advancement within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Briquetter Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!