Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Briquetting Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Briquetting Machine Operator so you can tailor your answers to impress potential employers.

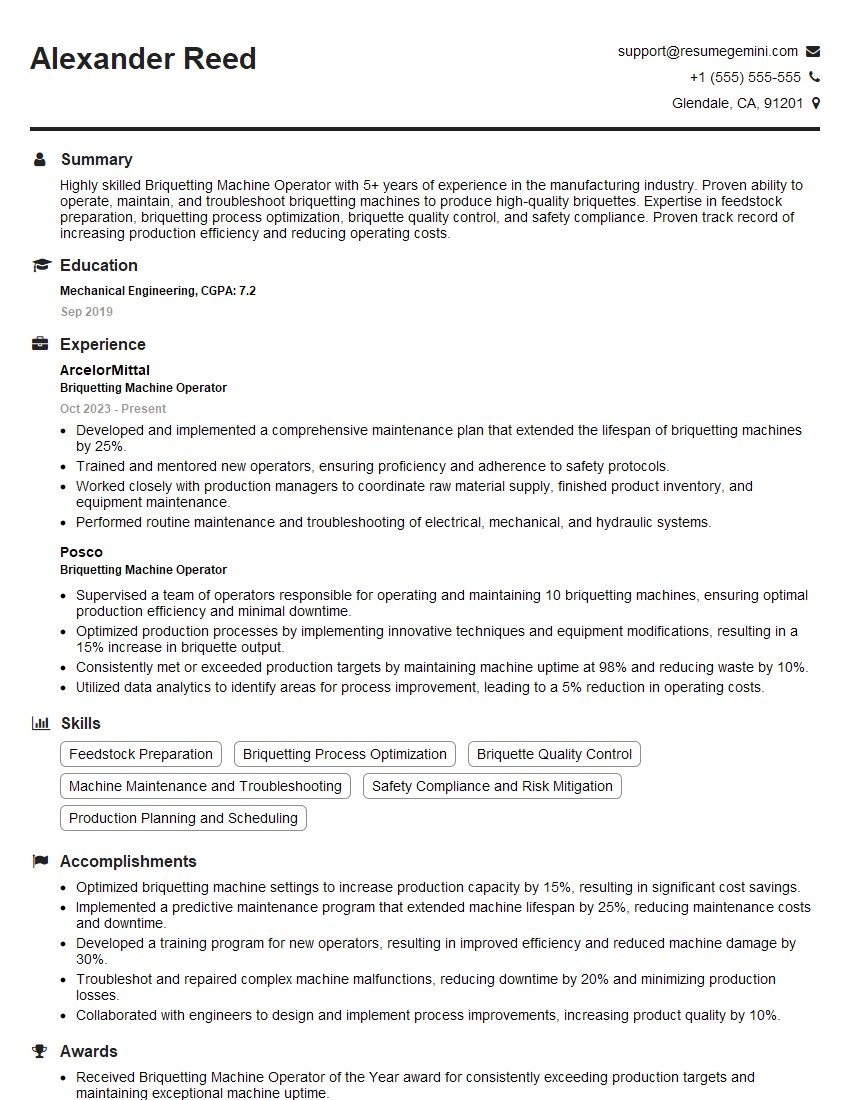

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Briquetting Machine Operator

1. Explain the key responsibilities of a Briquetting Machine Operator?

- Monitor and control the operation of briquetting machines

- Adjust machine settings to ensure proper briquette formation

- Maintain equipment and ensure adherence to safety protocols

2. What types of raw materials are commonly briquetted?

Biomass materials

- Wood chips

- Agricultural residues

Industrial materials

- Metal shavings

- Coal fines

3. Describe the different types of briquetting machines and their applications?

- Roller press: Used for high-density briquettes

- Screw press: Suitable for fibrous materials

- Extruder: Produces cylindrical briquettes with high strength

4. How do you ensure the quality and consistency of briquettes produced?

- Monitor raw material specifications

- Calibrate machine settings regularly

- Perform quality control checks on finished briquettes

5. Explain the importance of maintaining proper lubrication in briquetting machines?

- Reduces friction and wear, ensuring smooth operation

- Prevents overheating and damage to moving parts

- Extends the lifespan of the machine

6. What are the safety hazards associated with briquetting machines and how do you mitigate them?

- Moving parts: Wear appropriate safety gear and follow lockout/tagout procedures

- Dust and particulate matter: Use respiratory protection and minimize exposure

- High temperatures: Wear heat-resistant clothing and avoid touching hot surfaces

7. Explain the role of the moisture content in briquetting?

- Optimal moisture content improves briquette formation and strength

- Too low moisture can result in weak and crumbly briquettes

- Too high moisture can increase production time and reduce briquette quality

8. Describe the maintenance procedures for briquetting machines?

- Regular cleaning and inspection

- Replacement of worn parts

- Calibration and adjustment of machine settings

9. How do you troubleshoot common problems encountered in briquetting machine operation?

- Weak briquettes: Adjust moisture content, check binder addition

- Overheating: Ensure proper lubrication, check machine settings

- Blockages: Stop the machine, clear obstructions, check feed rate

10. What methods can be used to increase the efficiency of briquetting machines?

- Optimize raw material preparation

- Fine-tune machine settings based on material properties

- Implement automated control systems

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Briquetting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Briquetting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Briquetting Machine Operator is responsible for overseeing the operation and maintenance of briquetting machines, which compress loose materials into solid blocks or briquettes. The key job responsibilities include:

1. Machine Operation

intro paragraph

- Setting up, calibrating, and operating briquetting machines according to established procedures and specifications.

- Monitoring machine performance, including feed rate, pressure, and temperature, and making necessary adjustments to ensure optimal operation.

2. Material Handling

intro paragraph

- Loading and unloading raw materials and briquettes from the machine.

- Ensuring that the materials meet the required specifications for briquetting.

3. Quality Control

intro paragraph

- Inspecting briquettes to ensure they meet quality standards, such as density, shape, and strength.

- Conducting tests and making adjustments to the machine or process to maintain product quality.

4. Maintenance and Troubleshooting

intro paragraph

- Performing routine maintenance tasks, such as cleaning, lubricating, and replacing worn parts.

- Troubleshooting and repairing minor machine malfunctions.

- Reporting major issues to supervisors for resolution.

Interview Tips

Preparing thoroughly for a Briquetting Machine Operator interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

intro paragraph

- Visit the company’s website to learn about their products, services, and culture.

- Read industry publications and news articles to stay up-to-date with the latest trends and technologies in the briquetting industry.

2. Practice Answering Common Interview Questions

intro paragraph

- Prepare for questions about your experience with briquetting machines, quality control procedures, and troubleshooting techniques.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your skills and accomplishments.

3. Highlight Your Safety Awareness

intro paragraph

- Emphasize your understanding of safety protocols and your commitment to following them.

- Share examples of how you have identified and mitigated potential hazards in the workplace.

4. Showcase Your Team Skills

intro paragraph

- Discuss your ability to work effectively as part of a team and communicate clearly with colleagues.

- Provide examples of how you have collaborated with others to achieve common goals.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Briquetting Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!