Are you gearing up for a career in Bristle Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Bristle Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

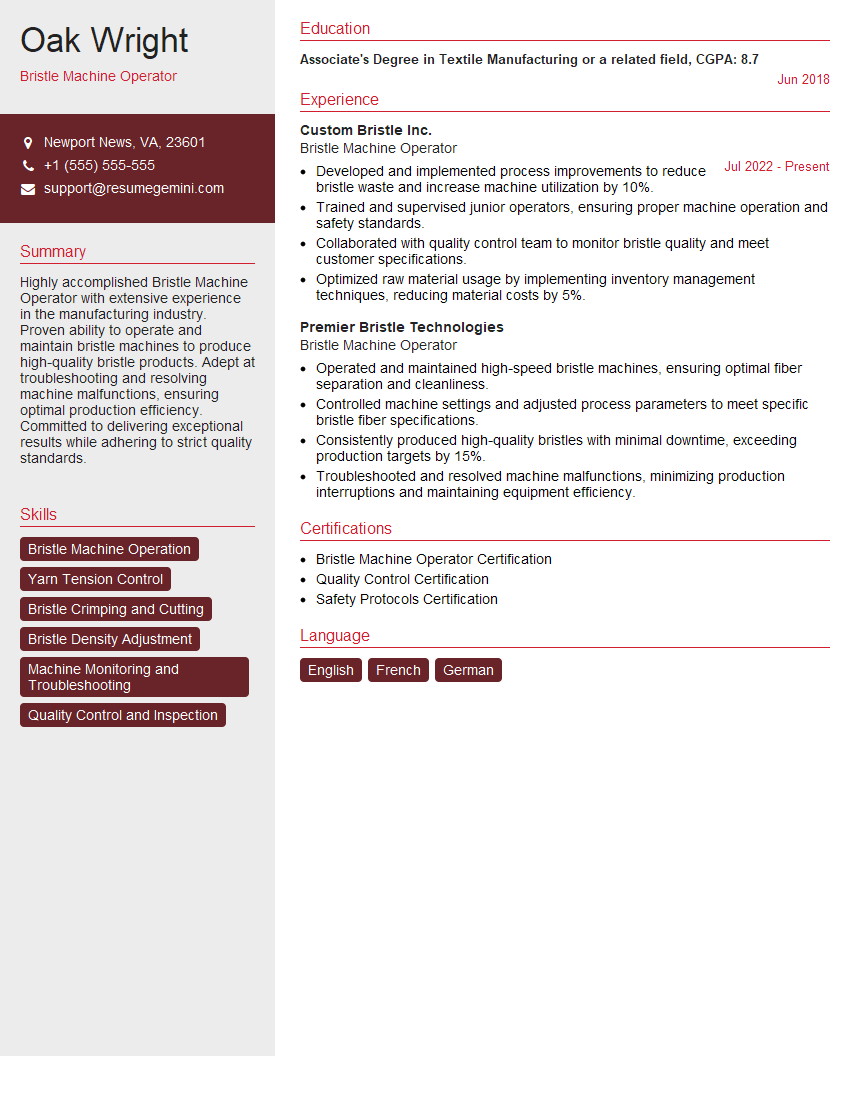

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bristle Machine Operator

1. What are the different types of bristle machines and their applications?

Bristle machines are classified into two main types based on the method used to insert bristles into the brush head:

- Manual Bristle Machine: Requires manual insertion of individual bristles, best suited for small-scale production or customized brushes.

- Automatic Bristle Machine: Equipped with a vibrating or oscillation mechanism that automatically inserts bristles into the brush head, suitable for high-volume production.

Applications of Bristle Machines:

- Production of various brushes, including toothbrushes, hairbrushes, paintbrushes, and industrial brushes.

- Insertion of bristles into cleaning tools, brooms, and brushes for machinery.

- Manufacturing of medical brushes and specialized brushes for technical applications.

2. Explain the process of setting up and operating a bristle machine.

Setting Up:

- Mount the appropriate brush head on the machine.

- Set the bristle feed rate and orientation.

- Calibrate the machine to ensure accurate bristle insertion.

Operation:

- Load the bristles into the machine hopper.

- Activate the machine to start the bristle insertion process.

- Monitor the machine’s operation and make adjustments as needed.

Troubleshooting:

- Identify and resolve any issues related to bristle feeding, orientation, or machine performance.

- Perform regular maintenance and cleaning to ensure optimal machine operation.

3. What are the safety precautions that must be followed when operating a bristle machine?

- Wear appropriate personal protective equipment (PPE), including gloves and safety glasses.

- Keep hands clear of moving parts during machine operation.

- Do not attempt to adjust or repair the machine while it is running.

- Follow proper lockout/tagout procedures before performing any maintenance or repairs.

- Ensure adequate ventilation in the work area to prevent inhalation of bristle dust.

4. What factors affect the quality of bristles inserted by a bristle machine?

- Bristle Material: Type and quality of bristle material (e.g., nylon, horsehair, synthetic) can impact bristle flexibility, durability, and resistance to wear.

- Bristle Length and Diameter: Bristle length and diameter determine the stiffness, density, and functionality of the brush.

- Bristle Orientation: Proper bristle orientation ensures optimal performance and effectiveness of the brush.

- Machine Settings: Accurate machine settings, including bristle feed rate and insertion depth, influence the quality of bristle insertion.

- Maintenance and Calibration: Regular machine maintenance and calibration ensure precise bristle insertion and prevent defects.

5. How do you troubleshoot common problems encountered with bristle machines?

- Bristle Jams: Check for any obstructions in the bristle feed system and adjust the feed rate accordingly.

- Uneven Bristle Insertion: Calibrate the machine and inspect the brush head for any damage or misalignment.

- Poor Bristle Retention: Verify that the bristles are inserted to the correct depth and consider using a different bristle adhesive if necessary.

- Machine Malfunctions: Check for mechanical issues, loose connections, or sensor failures, and refer to the manufacturer’s manual for repair procedures.

6. Explain the importance of maintaining and calibrating a bristle machine.

Importance of Maintenance:

- Prevents premature machine failures and costly repairs.

- Ensures optimal machine performance and bristle insertion quality.

- Promotes safety by preventing potential hazards.

Importance of Calibration:

- Guarantees accurate bristle insertion, length, and orientation.

- Optimizes brush performance and customer satisfaction.

- Minimizes production defects and waste.

7. Describe the different types of brushes that can be produced using a bristle machine.

- Industrial Brushes: Brushes designed for heavy-duty cleaning, scrubbing, and surface preparation in various industries.

- Household Brushes: Brushes for everyday tasks such as cleaning, sweeping, dusting, and personal grooming.

- Medical Brushes: Specialized brushes used in surgical procedures, dental care, and laboratory applications.

- Cosmetic Brushes: Brushes used in makeup application, including brushes for foundation, eyeshadow, and blush.

- Artistic Brushes: Brushes designed for painting, drawing, and other artistic endeavors.

8. How do you maintain the cleanliness and hygiene of a bristle machine?

- Regularly clean the machine and its components using appropriate cleaning agents.

- Remove any bristle debris or dust from the machine’s hopper and feed system.

- Inspect and clean the brush head to prevent bristle buildup and ensure proper hygiene.

- Adhere to manufacturer’s guidelines for periodic maintenance and cleaning intervals.

- Maintain a clean work environment to minimize airborne contaminants and improve machine hygiene.

9. What is the role of adhesives in bristle insertion, and how do you choose the right adhesive?

- Role of Adhesives: Adhesives provide a strong bond between the bristles and the brush head, ensuring bristle retention and durability.

- Choosing the Right Adhesive: Consider factors such as material compatibility, curing time, temperature resistance, and environmental conditions.

- Types of Adhesives: Common adhesives used in bristle insertion include cyanoacrylate, epoxy, and hot melt adhesives.

10. How do you ensure the accuracy and precision of bristle insertion?

- Precise Machine Calibration: Calibrate the machine regularly to ensure accurate bristle insertion depth and orientation.

- Quality Bristles: Use high-quality bristles that are consistent in length and diameter to minimize variations.

- Adequate Training: Train operators on proper machine setup and operation techniques to enhance precision.

- Quality Control Measures: Implement quality control procedures to inspect and verify the accuracy of bristle insertion.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bristle Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bristle Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bristle Machine Operators play a crucial role in manufacturing processes by operating and maintaining specialized machinery that produces bristles for various industrial applications. Their responsibilities include:

1. Production Operations

• Set up, operate, and monitor bristle machines according to established specifications and production schedules.

• Adjust machine settings, feed materials, and monitor product quality to ensure compliance with standards.

2. Machine Maintenance

• Perform routine maintenance tasks such as cleaning, lubrication, and minor repairs to ensure optimal machine performance.

• Identify potential mechanical issues and take corrective actions to prevent breakdowns and downtime.

3. Quality Control

• Inspect bristles for defects and ensure that they meet specified dimensions, strength, and durability requirements.

• Implement quality control procedures and report any non-conformance to supervisors.

4. Health and Safety

• Adhere to all safety regulations and guidelines to maintain a safe work environment.

• Wear appropriate personal protective equipment and follow established safety protocols.

Interview Tips

To ace an interview for a Bristle Machine Operator position, candidates should focus on showcasing the following:

1. Technical Skills and Experience

• Emphasize your proficiency in operating and maintaining bristle machines.

• Highlight your knowledge of machine settings, materials, and quality control procedures.

2. Problem-Solving Abilities

• Share examples of how you have identified and resolved mechanical issues or production challenges.

• Explain your approach to troubleshooting and implementing effective solutions.

3. Quality-Oriented Mindset

• Demonstrate your commitment to producing high-quality bristles that meet specifications.

• Describe your experience in implementing quality control measures and ensuring product conformance.

4. Safety Consciousness

• Highlight your understanding of safety protocols and your adherence to established guidelines.

• Emphasize your commitment to maintaining a safe and hazard-free work environment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bristle Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.